Mylar lamination offers superior durability and moisture resistance compared to foil lamination, making it ideal for protecting sensitive documents and packaging. While foil lamination provides a reflective, metallic finish that enhances visual appeal, Mylar lamination ensures long-lasting protection against wear and tear. Choosing between Mylar and foil lamination depends on whether durability or aesthetic shine is the primary requirement.

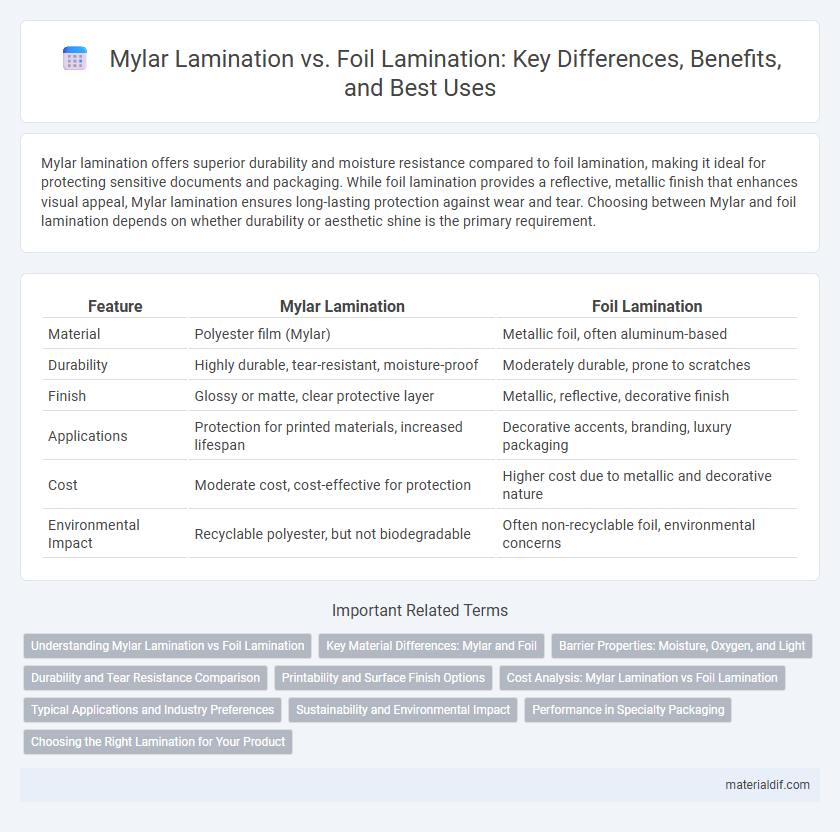

Table of Comparison

| Feature | Mylar Lamination | Foil Lamination |

|---|---|---|

| Material | Polyester film (Mylar) | Metallic foil, often aluminum-based |

| Durability | Highly durable, tear-resistant, moisture-proof | Moderately durable, prone to scratches |

| Finish | Glossy or matte, clear protective layer | Metallic, reflective, decorative finish |

| Applications | Protection for printed materials, increased lifespan | Decorative accents, branding, luxury packaging |

| Cost | Moderate cost, cost-effective for protection | Higher cost due to metallic and decorative nature |

| Environmental Impact | Recyclable polyester, but not biodegradable | Often non-recyclable foil, environmental concerns |

Understanding Mylar Lamination vs Foil Lamination

Mylar lamination uses a polyester film known for its durability, clarity, and heat resistance, making it ideal for protecting documents and packaging with a glossy or matte finish. Foil lamination involves applying a thin layer of metallic foil to surfaces, offering a decorative and reflective finish that enhances visual appeal but may be less flexible than Mylar. Understanding the difference centers on Mylar's protective strength and clarity versus foil's aesthetic enhancement for branding and luxury packaging.

Key Material Differences: Mylar and Foil

Mylar lamination utilizes polyethylene terephthalate (PET), known for its excellent clarity, durability, and resistance to moisture and chemicals, making it ideal for protective and insulating applications. Foil lamination, typically composed of thin layers of metal such as aluminum bonded to a substrate, offers superior reflectivity, barrier properties against light and oxygen, and enhanced aesthetic appeal with metallic finishes. The key material difference lies in Mylar's polyester base providing flexibility and transparency, whereas foil laminates emphasize metallic protection and decorative effects.

Barrier Properties: Moisture, Oxygen, and Light

Mylar lamination offers superior barrier properties against moisture, oxygen, and light, ensuring enhanced product protection and extended shelf life. Its polyethylene terephthalate (PET) composition provides excellent moisture resistance and low oxygen permeability compared to traditional foil lamination. While foil lamination also effectively blocks oxygen and light, Mylar's clarity and durability make it preferable for applications requiring both high barrier performance and visual appeal.

Durability and Tear Resistance Comparison

Mylar lamination offers superior durability and tear resistance compared to foil lamination due to its polyester base, which provides enhanced strength and flexibility. Unlike foil lamination, Mylar resists cracking and peeling under stress, making it ideal for long-lasting applications. Its high tensile strength ensures protection against wear and tear, extending the lifespan of laminated materials significantly.

Printability and Surface Finish Options

Mylar lamination offers superior printability due to its smooth, non-porous surface that enhances ink adhesion and color vibrancy, making it ideal for high-definition graphics. Foil lamination provides a distinct metallic surface finish with limited printability, often used to create eye-catching accents rather than full-surface prints. The choice between Mylar and foil lamination depends on the desired balance between detailed print clarity and decorative metallic effects.

Cost Analysis: Mylar Lamination vs Foil Lamination

Mylar lamination typically incurs higher initial material costs compared to foil lamination but offers enhanced durability and heat resistance, potentially reducing long-term replacement expenses. Foil lamination, while generally more affordable upfront, may require more frequent maintenance and replacement due to its lower resilience in high-stress environments. Evaluating cost-effectiveness depends on application longevity, with Mylar lamination favoring bulk, high-performance uses and foil lamination suitable for budget-conscious, short-term projects.

Typical Applications and Industry Preferences

Mylar lamination is widely preferred in electronics, packaging, and printing industries due to its superior durability, clarity, and heat resistance, making it ideal for protective covers and flexible circuits. Foil lamination is commonly used in luxury packaging and decorative applications, favored for its metallic sheen and ability to enhance product aesthetics. Industries requiring robust, transparent layers opt for Mylar, while those emphasizing visual appeal choose foil lamination for branding and promotional materials.

Sustainability and Environmental Impact

Mylar lamination utilizes PET film known for its recyclability and lower environmental footprint compared to traditional foil lamination, which often incorporates metalized layers that complicate recycling processes. The energy consumption in manufacturing Mylar sheets is generally lower, resulting in reduced greenhouse gas emissions relative to foil lamination production. Businesses prioritizing sustainability benefit from Mylar lamination through enhanced material recovery and minimized ecological impact during both production and post-consumer disposal phases.

Performance in Specialty Packaging

Mylar lamination offers superior barrier properties, enhancing moisture and oxygen resistance critical for specialty packaging applications requiring extended shelf life. Foil lamination provides excellent light and aroma protection but may lack the flexibility and tensile strength of Mylar films. In high-performance packaging, Mylar lamination ensures durability and clarity, making it ideal for products demanding both visibility and preservation.

Choosing the Right Lamination for Your Product

Mylar lamination provides exceptional durability, moisture resistance, and clarity, making it ideal for products requiring long-lasting protection and visual appeal. Foil lamination, characterized by its metallic finish and premium aesthetic, enhances product attractiveness but offers less flexibility and moisture resistance compared to Mylar. Selecting the right lamination depends on balancing the need for visual impact with functional protection based on product type and usage conditions.

Mylar Lamination vs Foil Lamination Infographic

materialdif.com

materialdif.com