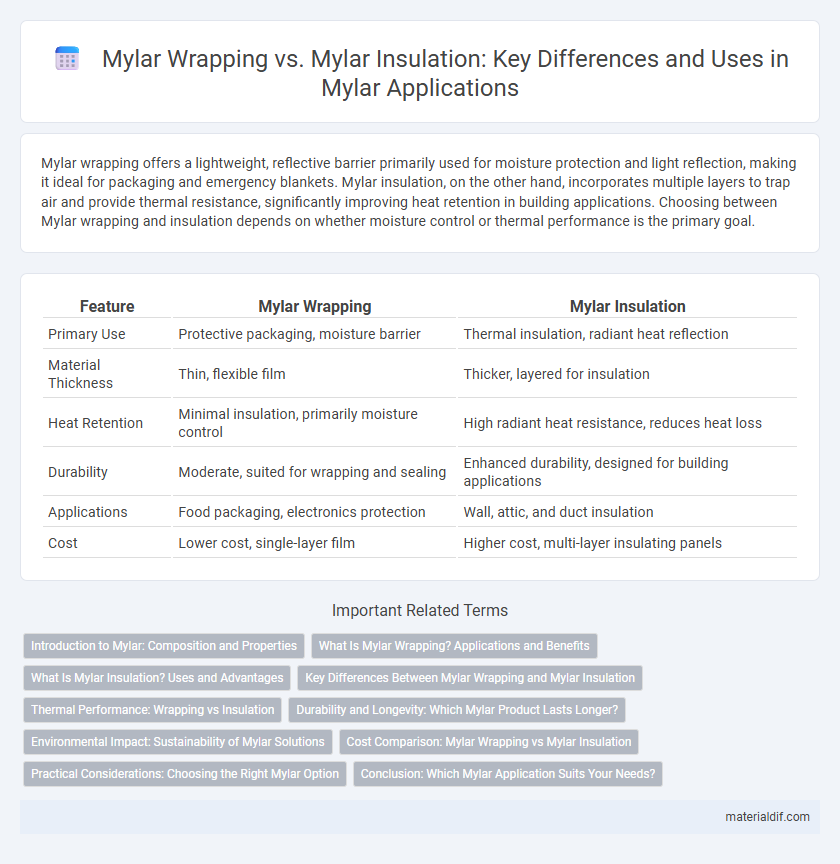

Mylar wrapping offers a lightweight, reflective barrier primarily used for moisture protection and light reflection, making it ideal for packaging and emergency blankets. Mylar insulation, on the other hand, incorporates multiple layers to trap air and provide thermal resistance, significantly improving heat retention in building applications. Choosing between Mylar wrapping and insulation depends on whether moisture control or thermal performance is the primary goal.

Table of Comparison

| Feature | Mylar Wrapping | Mylar Insulation |

|---|---|---|

| Primary Use | Protective packaging, moisture barrier | Thermal insulation, radiant heat reflection |

| Material Thickness | Thin, flexible film | Thicker, layered for insulation |

| Heat Retention | Minimal insulation, primarily moisture control | High radiant heat resistance, reduces heat loss |

| Durability | Moderate, suited for wrapping and sealing | Enhanced durability, designed for building applications |

| Applications | Food packaging, electronics protection | Wall, attic, and duct insulation |

| Cost | Lower cost, single-layer film | Higher cost, multi-layer insulating panels |

Introduction to Mylar: Composition and Properties

Mylar, a polyester film made from stretched polyethylene terephthalate (PET), is known for its strength, durability, and reflective properties. Mylar wrapping utilizes its airtight and moisture-resistant qualities for packaging and protection, preserving freshness and prolonging shelf life. In contrast, Mylar insulation leverages its reflective surface to reduce heat transfer by reflecting radiant heat, making it effective in thermal insulation applications.

What Is Mylar Wrapping? Applications and Benefits

Mylar wrapping involves covering objects with a thin, reflective polyester film to enhance protection against moisture, dust, and light, widely used in packaging electronics and food preservation. Its applications include shielding sensitive items from environmental damage, improving shelf life, and providing a lightweight barrier with excellent tensile strength. Benefits of Mylar wrapping encompass durability, resistance to chemical corrosion, and the ability to maintain product integrity through effective thermal insulation properties.

What Is Mylar Insulation? Uses and Advantages

Mylar insulation consists of reflective polyester film designed to reduce heat transfer by reflecting radiant heat away from surfaces in buildings and automotive applications. It is commonly used in attics, walls, and HVAC ducts to improve energy efficiency, lower heating and cooling costs, and enhance indoor comfort. The key advantages of Mylar insulation include high thermal reflectivity, moisture resistance, lightweight properties, and easy installation compared to traditional insulation materials.

Key Differences Between Mylar Wrapping and Mylar Insulation

Mylar wrapping serves primarily as a reflective barrier to retain heat and protect surfaces from moisture and contaminants, whereas Mylar insulation combines reflective properties with multiple layers to provide enhanced thermal resistance and reduce heat transfer. Mylar insulation typically includes air pockets or foam layers that improve its efficacy in temperature regulation, while Mylar wrapping is thinner and mainly focuses on reflection and moisture control. Understanding these key differences helps in selecting the appropriate Mylar product for specific needs such as packaging, thermal blankets, or building insulation.

Thermal Performance: Wrapping vs Insulation

Mylar wrapping mainly serves as a radiant barrier, reflecting up to 97% of radiant heat and reducing thermal transfer in multi-layer insulation systems. In contrast, Mylar insulation combines the reflective properties of Mylar with air pockets or foam layers to deliver improved overall thermal resistance (R-value), enhancing both conductive and radiant heat control. For optimal thermal performance, Mylar insulation outperforms simple Mylar wrapping by reducing heat flow through conduction, convection, and radiation.

Durability and Longevity: Which Mylar Product Lasts Longer?

Mylar insulation typically offers greater durability and longevity compared to Mylar wrapping due to its thicker, multi-layered construction designed for thermal resistance and moisture protection. Mylar wrapping, often thinner and more flexible, is prone to tearing and degradation when exposed to environmental stressors over time. For long-term applications requiring sustained performance, Mylar insulation provides a more reliable solution with enhanced lifespan.

Environmental Impact: Sustainability of Mylar Solutions

Mylar wrapping and Mylar insulation both utilize polyethylene terephthalate (PET) film, but their environmental impacts differ based on usage and disposal. Mylar wrapping is often single-use and contributes to plastic waste, whereas Mylar insulation, designed for long-term thermal efficiency, offers energy-saving benefits that reduce carbon emissions over time. Recycling challenges exist for both, but advancements in PET recycling improve the sustainability profile of Mylar solutions overall.

Cost Comparison: Mylar Wrapping vs Mylar Insulation

Mylar wrapping typically costs less than Mylar insulation due to its thinner material and simpler application process, making it a budget-friendly option for surface protection and light reflective purposes. Mylar insulation, which combines multiple layers including foil and insulating substrates, offers superior thermal resistance but at a higher price point that reflects its enhanced energy-saving benefits. Evaluating projects based on performance needs and budget constraints helps determine the cost-effectiveness of Mylar wrapping versus Mylar insulation.

Practical Considerations: Choosing the Right Mylar Option

Mylar wrapping provides a versatile moisture and vapor barrier ideal for protecting items from humidity, while Mylar insulation offers superior thermal resistance for temperature control in buildings or packaging. Practical considerations include the specific application environment, with Mylar insulation better suited for energy efficiency and Mylar wrapping preferred for lightweight, protective coverage. Cost, installation complexity, and desired durability also influence the choice between Mylar wrapping and insulation.

Conclusion: Which Mylar Application Suits Your Needs?

Mylar wrapping excels in protecting items from moisture, dust, and light, making it ideal for packaging and preservation purposes. Mylar insulation, on the other hand, provides superior thermal resistance by reflecting radiant heat, suitable for enhancing energy efficiency in buildings or garments. Choosing between Mylar wrapping and insulation depends on whether your priority is protection or thermal control, with each serving distinct functional needs.

Mylar Wrapping vs Mylar Insulation Infographic

materialdif.com

materialdif.com