Mylar sheeting offers a thicker, more durable option ideal for heavy-duty applications, while Mylar film is thinner and flexible, better suited for lightweight or decorative uses. The choice between Mylar sheeting and Mylar film depends on the required strength, thickness, and intended functionality of the project. Both materials provide excellent moisture resistance and clarity, making them popular in packaging, insulation, and protective coverings.

Table of Comparison

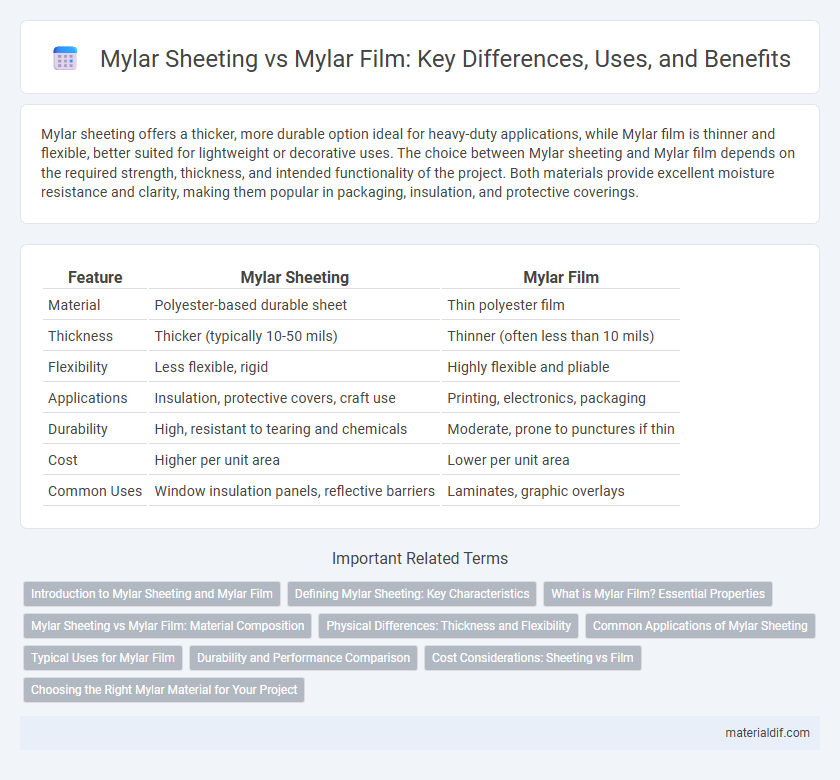

| Feature | Mylar Sheeting | Mylar Film |

|---|---|---|

| Material | Polyester-based durable sheet | Thin polyester film |

| Thickness | Thicker (typically 10-50 mils) | Thinner (often less than 10 mils) |

| Flexibility | Less flexible, rigid | Highly flexible and pliable |

| Applications | Insulation, protective covers, craft use | Printing, electronics, packaging |

| Durability | High, resistant to tearing and chemicals | Moderate, prone to punctures if thin |

| Cost | Higher per unit area | Lower per unit area |

| Common Uses | Window insulation panels, reflective barriers | Laminates, graphic overlays |

Introduction to Mylar Sheeting and Mylar Film

Mylar sheeting and Mylar film both originate from stretched polyethylene terephthalate (PET) polyester resin, known for durability and clarity. Mylar sheeting is thicker and more rigid, ideal for insulation, protective covers, and insulation blankets, while Mylar film is thinner, flexible, and used in packaging, graphics, and electronic applications. Understanding the distinction between the thickness and application of Mylar sheeting versus film is essential for selecting the right material for specific industrial or commercial uses.

Defining Mylar Sheeting: Key Characteristics

Mylar sheeting is a durable polyester film known for its high tensile strength, chemical stability, and excellent dimensional stability, making it ideal for industrial, electrical, and packaging applications. Unlike thinner Mylar film variants primarily used for insulation or decorative purposes, Mylar sheeting offers greater thickness and rigidity, enhancing its protective function. Key characteristics include its resistance to moisture, UV radiation, and temperature extremes, which ensure long-lasting performance in demanding environments.

What is Mylar Film? Essential Properties

Mylar film is a thin, flexible polyester material known for its high tensile strength, chemical stability, and excellent barrier properties against moisture, gases, and aromas. Unlike thicker Mylar sheeting, the film variant is often used in electronics, packaging, and insulation due to its lightweight and durable nature. Its essential properties include transparency, heat resistance, and electrical insulation, making it ideal for applications requiring flexibility and protection.

Mylar Sheeting vs Mylar Film: Material Composition

Mylar sheeting and Mylar film primarily differ in thickness and application, with sheeting being thicker and more rigid than the thin, flexible film. Both are composed of biaxially-oriented polyethylene terephthalate (BoPET), a polyester resin known for its strength, chemical stability, and electrical insulating properties. The increased durability of Mylar sheeting makes it suitable for industrial uses, while Mylar film is often used in packaging, insulation, and graphic arts.

Physical Differences: Thickness and Flexibility

Mylar sheeting is typically thicker, ranging from 3 to 10 mils, providing greater rigidity and durability for structural applications, while Mylar film is much thinner, often between 0.5 to 2 mils, allowing for higher flexibility and easier conformability to curved surfaces. The thickness difference directly impacts their mechanical properties, with sheeting offering enhanced dimensional stability and film delivering superior pliability for wrapping or insulation purposes. Selecting between Mylar sheeting and film depends on the required balance of stiffness versus flexibility for specific industrial or consumer uses.

Common Applications of Mylar Sheeting

Mylar sheeting is widely used in insulation, emergency blankets, and packaging due to its excellent thermal resistance and durability. Its ability to reflect heat and withstand moisture makes it ideal for protective covers and insulation barriers in buildings and electronics. Compared to Mylar film, sheeting is thicker and more robust, making it suitable for heavy-duty applications such as greenhouse covers and solar blankets.

Typical Uses for Mylar Film

Mylar film is commonly used for packaging due to its excellent barrier properties against moisture, oxygen, and light, extending product shelf life in food and pharmaceuticals. It is also favored for insulation in electronic devices and solar panels because of its electrical conductivity and thermal resistance. Additionally, Mylar film is widely utilized in graphic arts and printing applications for its clarity and durability.

Durability and Performance Comparison

Mylar sheeting offers superior durability with enhanced resistance to punctures, tears, and environmental factors compared to Mylar film, making it ideal for long-term applications. Mylar film, being thinner and more flexible, excels in performance where lightweight and ease of application are crucial but may compromise longevity under harsh conditions. For applications demanding resilience and consistent performance, Mylar sheeting provides a robust solution, whereas Mylar film suits short-term or precise use cases.

Cost Considerations: Sheeting vs Film

Mylar sheeting generally costs more upfront due to its thicker gauge and enhanced durability, making it ideal for applications requiring long-term stability. Mylar film, being thinner and more flexible, offers a cost-effective solution for short-term or less demanding uses, reducing material expenses. Choosing between sheeting and film depends on balancing budget constraints with performance needs, where sheeting offers longevity at higher initial costs and film prioritizes economical flexibility.

Choosing the Right Mylar Material for Your Project

Mylar sheeting offers excellent durability and thickness, making it ideal for insulation and protective covers, while Mylar film provides a thinner, more flexible option perfect for lightweight packaging and reflective surfaces. Understanding the specific requirements of your project--such as tensile strength, transparency, and heat resistance--guides the choice between sheeting and film. Selecting the appropriate Mylar material ensures optimal performance, longevity, and cost-efficiency tailored to your application's demands.

Mylar Sheeting vs Mylar Film Infographic

materialdif.com

materialdif.com