Mylar lamination offers superior clarity, durability, and moisture resistance compared to polyethylene lamination, making it ideal for preserving documents and packaging sensitive items. Polyethylene lamination is more flexible and cost-effective but provides less protection against tearing and environmental factors. Choosing between Mylar and polyethylene depends on the balance between protection needs and budget constraints.

Table of Comparison

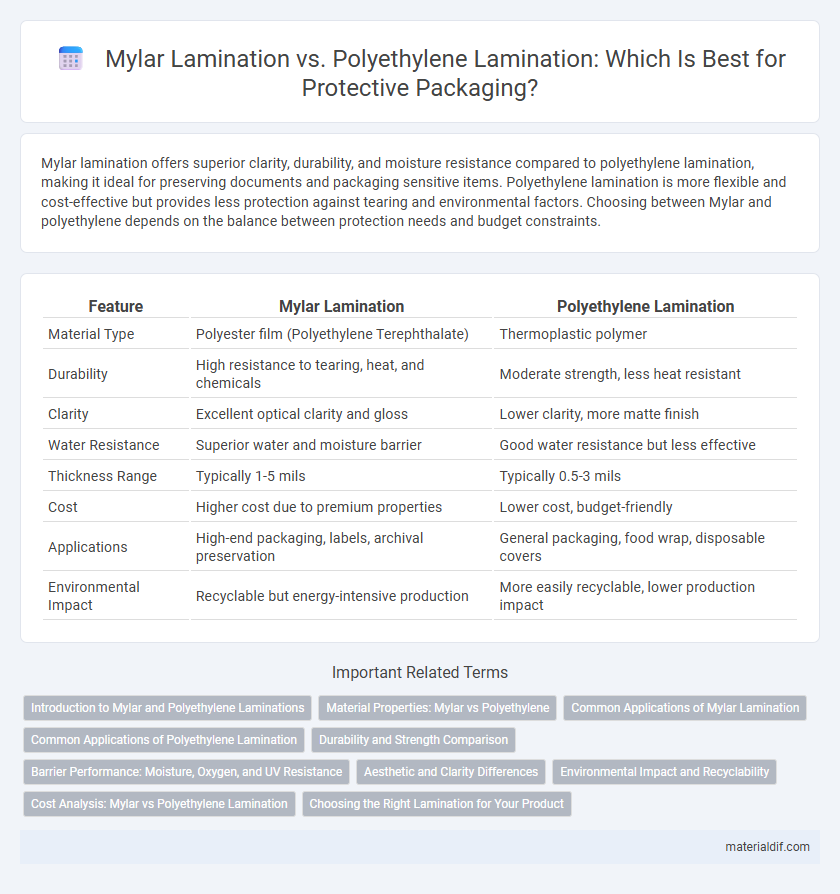

| Feature | Mylar Lamination | Polyethylene Lamination |

|---|---|---|

| Material Type | Polyester film (Polyethylene Terephthalate) | Thermoplastic polymer |

| Durability | High resistance to tearing, heat, and chemicals | Moderate strength, less heat resistant |

| Clarity | Excellent optical clarity and gloss | Lower clarity, more matte finish |

| Water Resistance | Superior water and moisture barrier | Good water resistance but less effective |

| Thickness Range | Typically 1-5 mils | Typically 0.5-3 mils |

| Cost | Higher cost due to premium properties | Lower cost, budget-friendly |

| Applications | High-end packaging, labels, archival preservation | General packaging, food wrap, disposable covers |

| Environmental Impact | Recyclable but energy-intensive production | More easily recyclable, lower production impact |

Introduction to Mylar and Polyethylene Laminations

Mylar lamination uses biaxially oriented polyethylene terephthalate (BoPET) film, offering superior tensile strength, clarity, and resistance to heat and moisture compared to polyethylene lamination, which utilizes low-density polyethylene (LDPE) film known for flexibility and cost-effectiveness. Mylar provides excellent barrier properties against oxygen and moisture, making it ideal for packaging sensitive products, while polyethylene lamination excels in applications requiring pliability and sealability. The choice between Mylar and polyethylene lamination depends on specific product protection needs, durability requirements, and budget considerations.

Material Properties: Mylar vs Polyethylene

Mylar lamination offers superior tensile strength, dimensional stability, and resistance to moisture and chemicals compared to polyethylene lamination, making it ideal for high-performance packaging and protective applications. Polyethylene lamination provides excellent flexibility, impact resistance, and cost-effectiveness, suitable for short-term use and lightweight products. The polyester base of Mylar ensures enhanced clarity and thermal resistance, while polyethylene's lower melting point affects durability under high temperatures.

Common Applications of Mylar Lamination

Mylar lamination is commonly used in applications requiring high durability, clarity, and moisture resistance, such as archival document protection, flexible packaging, and electrical insulation. Unlike polyethylene lamination, which is typically favored for low-cost, disposable packaging, Mylar offers superior barrier properties against oxygen and UV light, making it ideal for food packaging and artwork preservation. Its heat resistance and tensile strength enable Mylar lamination to perform well in industrial uses like printed circuit boards and safety helmets.

Common Applications of Polyethylene Lamination

Polyethylene lamination is widely used in packaging industries for food products, pharmaceuticals, and consumer goods due to its excellent moisture resistance and flexibility. Its common applications include protective wrappers, pouches, and bags that require durable, lightweight barrier properties. Polyethylene's cost-effectiveness and recyclability make it a preferred choice for disposable packaging solutions.

Durability and Strength Comparison

Mylar lamination offers superior durability and strength compared to polyethylene lamination, with enhanced resistance to moisture, chemicals, and tearing. Its polyester film composition provides excellent dimensional stability and higher tensile strength, making it ideal for applications requiring long-term protection. Polyethylene lamination, while flexible and cost-effective, does not match Mylar's robustness in harsh environmental conditions or heavy-use scenarios.

Barrier Performance: Moisture, Oxygen, and UV Resistance

Mylar lamination offers superior barrier performance compared to polyethylene lamination, exhibiting high resistance to moisture, oxygen, and UV radiation. This enhanced protection is due to Mylar's polyester composition, which provides excellent impermeability, effectively preserving product freshness and extending shelf life. In contrast, polyethylene laminates have lower barrier properties, making them less suitable for applications requiring stringent moisture, oxygen, and UV protection.

Aesthetic and Clarity Differences

Mylar lamination offers superior clarity and a glossy finish that enhances color vibrancy and sharpness, making it ideal for high-quality prints and photographs. In contrast, polyethylene lamination provides a more matte appearance with less optical clarity, resulting in a subdued aesthetic suitable for everyday packaging. The higher transparency and smooth surface of Mylar create a visually striking effect, while polyethylene's texture may slightly diffuse images and colors.

Environmental Impact and Recyclability

Mylar lamination offers superior durability and moisture resistance compared to polyethylene lamination, but it presents challenges in recyclability due to its polyester composition, which requires specialized processing. Polyethylene lamination is more environmentally friendly, as it is easier to recycle and produces fewer greenhouse gas emissions during manufacturing. Choosing polyethylene over Mylar can significantly reduce the environmental footprint of laminated products while maintaining adequate protection for many applications.

Cost Analysis: Mylar vs Polyethylene Lamination

Mylar lamination generally incurs higher upfront costs compared to polyethylene lamination due to the premium polyester film material and superior durability. However, Mylar offers extended lifespan and enhanced protection against moisture, UV rays, and abrasion, reducing long-term replacement expenses. Polyethylene lamination provides a cost-effective option for short-term applications but may require more frequent re-lamination, increasing cumulative costs over time.

Choosing the Right Lamination for Your Product

Mylar lamination offers superior durability, high tensile strength, and excellent moisture and gas barrier properties, making it ideal for products requiring long-lasting protection and enhanced appearance. Polyethylene lamination provides cost-effective flexibility and effective moisture resistance, suitable for less demanding packaging needs or items requiring more pliability. Selecting the right lamination depends on product requirements such as barrier performance, aesthetic appeal, and budget constraints to ensure optimal preservation and presentation.

Mylar Lamination vs Polyethylene Lamination Infographic

materialdif.com

materialdif.com