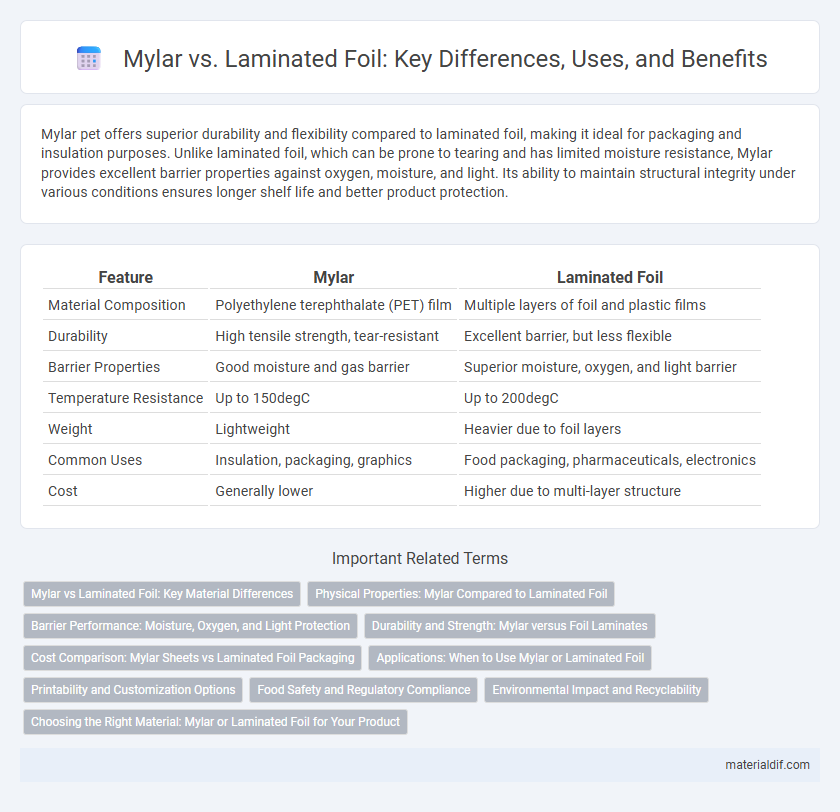

Mylar pet offers superior durability and flexibility compared to laminated foil, making it ideal for packaging and insulation purposes. Unlike laminated foil, which can be prone to tearing and has limited moisture resistance, Mylar provides excellent barrier properties against oxygen, moisture, and light. Its ability to maintain structural integrity under various conditions ensures longer shelf life and better product protection.

Table of Comparison

| Feature | Mylar | Laminated Foil |

|---|---|---|

| Material Composition | Polyethylene terephthalate (PET) film | Multiple layers of foil and plastic films |

| Durability | High tensile strength, tear-resistant | Excellent barrier, but less flexible |

| Barrier Properties | Good moisture and gas barrier | Superior moisture, oxygen, and light barrier |

| Temperature Resistance | Up to 150degC | Up to 200degC |

| Weight | Lightweight | Heavier due to foil layers |

| Common Uses | Insulation, packaging, graphics | Food packaging, pharmaceuticals, electronics |

| Cost | Generally lower | Higher due to multi-layer structure |

Mylar vs Laminated Foil: Key Material Differences

Mylar is a polyester film known for its high tensile strength, chemical stability, and excellent electrical insulation properties, making it ideal for packaging, insulation, and protective applications. Laminated foil combines metal foil, typically aluminum, with plastic layers to enhance barrier protection against moisture, oxygen, and light, crucial for food and pharmaceutical packaging. Unlike laminated foil, Mylar offers superior clarity and flexibility, while laminated foil provides enhanced barrier performance but less transparency and rigidity.

Physical Properties: Mylar Compared to Laminated Foil

Mylar exhibits superior tensile strength and flexibility compared to laminated foil, making it more resistant to tearing and punctures. Its higher clarity and lower permeability enhance its barrier properties, providing better protection against moisture, oxygen, and UV light. In contrast, laminated foil typically offers greater heat resistance but sacrifices flexibility and transparency, impacting its suitability for various packaging applications.

Barrier Performance: Moisture, Oxygen, and Light Protection

Mylar exhibits superior barrier performance compared to laminated foil, effectively blocking moisture, oxygen, and light to preserve product integrity. The polyester structure of Mylar offers exceptional resistance to gas transmission, significantly reducing oxygen infiltration and extending shelf life. Its high tensile strength and low permeability make Mylar an optimal choice for applications requiring advanced protection against environmental factors.

Durability and Strength: Mylar versus Foil Laminates

Mylar exhibits superior durability and tensile strength compared to laminated foil, making it more resistant to tearing and punctures under stress. Unlike laminated foil, Mylar maintains flexibility without compromising structural integrity, ensuring prolonged protection against environmental factors like moisture and UV exposure. Its enhanced mechanical properties make Mylar ideal for applications requiring reliable and long-lasting barrier performance.

Cost Comparison: Mylar Sheets vs Laminated Foil Packaging

Mylar sheets generally offer a cost-effective solution compared to laminated foil packaging, as their production involves fewer material layers and simpler manufacturing processes. Laminated foil packaging tends to be more expensive due to multiple layer laminations, including aluminum and polymer films, which provide enhanced barrier properties but increase material and processing costs. Businesses seeking budget-friendly packaging often prefer Mylar sheets for applications where moderate moisture and oxygen resistance suffice, whereas laminated foil is chosen for premium protection despite higher expenses.

Applications: When to Use Mylar or Laminated Foil

Mylar offers superior tensile strength and flexibility, making it ideal for applications requiring durability and lightweight protection, such as insulation, packaging, and emergency blankets. Laminated foil excels in moisture and odor barriers, commonly used in food packaging and pharmaceutical products to preserve freshness and extend shelf life. Choose Mylar for high-performance thermal and electrical insulation, while laminated foil suits environments demanding enhanced barrier properties against external contaminants.

Printability and Customization Options

Mylar offers superior printability compared to laminated foil due to its smooth, non-porous surface, allowing for vibrant, high-resolution graphics. Customization options with Mylar are extensive, including various colors, finishes, and thicknesses that enhance branding versatility. Laminated foil, while durable, often limits detailed printing and colors, reducing customization flexibility.

Food Safety and Regulatory Compliance

Mylar provides superior food safety due to its high barrier properties against oxygen, moisture, and contaminants, ensuring extended shelf life and freshness compared to laminated foil. Regulatory compliance is enhanced with Mylar packaging as it meets FDA and EU food contact material standards, reducing the risk of chemical migration. Laminated foil, while effective, often fails to match Mylar's consistent performance in preserving product integrity under stringent safety regulations.

Environmental Impact and Recyclability

Mylar and laminated foil differ significantly in environmental impact and recyclability, with Mylar being a type of polyester film that is more easily recyclable due to its homogenous material composition. Laminated foil, often composed of multiple layers including aluminum and plastic films, poses greater challenges for recycling and usually ends up in landfills. Choosing Mylar over laminated foil supports reduced environmental footprint by enabling more efficient recycling processes and lowering the volume of non-biodegradable waste.

Choosing the Right Material: Mylar or Laminated Foil for Your Product

Mylar offers superior durability, excellent moisture and gas barrier properties, and flexibility, making it ideal for packaging sensitive products like electronics and food. Laminated foil provides enhanced thermal insulation and better protection against light and odor, suitable for items requiring extended shelf life and high barrier performance. Selecting between Mylar and laminated foil depends on your product's specific protection needs, environmental exposure, and cost considerations.

Mylar vs Laminated Foil Infographic

materialdif.com

materialdif.com