Mylar reflection creates a highly reflective surface that efficiently bounces light in a focused manner, enhancing brightness and intensity for pet environments. In contrast, polycarbonate diffusion spreads light evenly, reducing glare and softening shadows to create a more uniform lighting effect. Choosing between Mylar and polycarbonate depends on whether concentrated illumination or gentle, diffused light best suits your pet's needs.

Table of Comparison

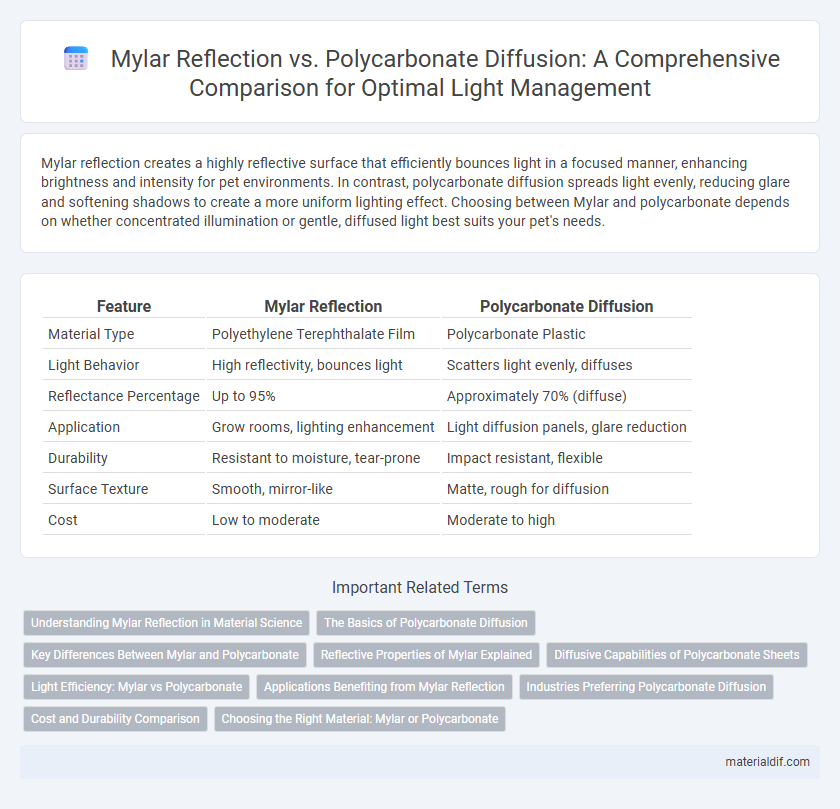

| Feature | Mylar Reflection | Polycarbonate Diffusion |

|---|---|---|

| Material Type | Polyethylene Terephthalate Film | Polycarbonate Plastic |

| Light Behavior | High reflectivity, bounces light | Scatters light evenly, diffuses |

| Reflectance Percentage | Up to 95% | Approximately 70% (diffuse) |

| Application | Grow rooms, lighting enhancement | Light diffusion panels, glare reduction |

| Durability | Resistant to moisture, tear-prone | Impact resistant, flexible |

| Surface Texture | Smooth, mirror-like | Matte, rough for diffusion |

| Cost | Low to moderate | Moderate to high |

Understanding Mylar Reflection in Material Science

Mylar reflection involves the highly reflective surface properties of biaxially-oriented polyethylene terephthalate (BoPET) film, which exhibits excellent specular reflection with a reflectivity often exceeding 90%, making it ideal for applications requiring efficient light redirection. In contrast, polycarbonate diffusion properties scatter light due to their microstructured or frosted surfaces, resulting in diffuse reflection that reduces glare but lowers overall reflectivity. Understanding Mylar's reflection characteristics is essential in material science for optimizing light management in fields such as solar energy, optical devices, and thermal insulation.

The Basics of Polycarbonate Diffusion

Polycarbonate diffusion uses a polymer structure that scatters light, resulting in even illumination and reduced glare compared to Mylar's reflective surface. This diffusion property makes polycarbonate ideal for applications requiring soft, uniform light distribution, such as in lighting panels and display screens. Its ability to minimize hotspots enhances visual comfort, contrasting with Mylar's sharp, mirror-like reflection.

Key Differences Between Mylar and Polycarbonate

Mylar offers high reflectivity with a smooth, mirror-like surface that optimizes light reflection in applications such as grow rooms and solar panels, whereas polycarbonate provides superior light diffusion due to its translucent, impact-resistant properties ideal for evenly distributing light. Mylar's thin, flexible film allows for easy installation and superior UV resistance, while polycarbonate sheets are thicker, more durable, and resist physical damage better but with less reflective efficiency. The key differences lie in Mylar's ability to maximize light reflection versus polycarbonate's strength in light diffusion and structural robustness.

Reflective Properties of Mylar Explained

Mylar offers superior reflective properties due to its highly polished metallic surface, which efficiently bounces light with minimal absorption, making it ideal for applications requiring intense light reflection. Unlike polycarbonate diffusion that scatters light to reduce glare and evenly distribute illumination, Mylar maintains a sharp, focused reflection, preserving light intensity and directionality. This characteristic makes Mylar a preferred choice for grow rooms, solar reflectors, and lighting fixtures where maximizing light reflection is crucial.

Diffusive Capabilities of Polycarbonate Sheets

Polycarbonate sheets excel in diffusive capabilities due to their inherent molecular structure, which scatters light uniformly, reducing glare and hotspots compared to Mylar reflection. Unlike the specular reflection of Mylar that directs light in a concentrated manner, polycarbonate diffuses illumination evenly across surfaces, enhancing visual comfort and reducing eye strain. This makes polycarbonate sheets ideal for applications requiring soft, consistent light distribution such as in lighting panels and protective eyewear.

Light Efficiency: Mylar vs Polycarbonate

Mylar offers superior light efficiency due to its highly reflective surface, reflecting up to 95% of light and minimizing energy loss in grow rooms or lighting applications. In contrast, polycarbonate diffuses light, reducing glare but typically reflecting only around 70-80%, which results in lower overall light intensity. Choosing Mylar maximizes the effective light output, making it the preferred material for applications needing optimal light reflection and energy conservation.

Applications Benefiting from Mylar Reflection

Mylar reflection offers superior light control and high reflectivity, making it ideal for applications in hydroponic grow rooms and photography studios where maximizing light efficiency is crucial. Its smooth, reflective surface enhances image clarity and evenly distributes light, improving plant growth and visual results compared to polycarbonate diffusion, which scatters light and reduces intensity. Industries aiming for precise light management and energy efficiency benefit significantly from Mylar's reflective properties.

Industries Preferring Polycarbonate Diffusion

Industries such as automotive, aerospace, and electronics prioritize polycarbonate diffusion over Mylar reflection due to polycarbonate's superior impact resistance, thermal stability, and light diffusion properties. Unlike Mylar, which offers high reflectivity, polycarbonate diffusion enhances uniform light distribution and reduces glare, critical for safety and visual performance in these sectors. This preference supports advanced applications requiring durable, lightweight materials with effective optical management.

Cost and Durability Comparison

Mylar offers high reflectivity at a lower cost compared to polycarbonate, making it a budget-friendly option for reflective applications. Polycarbonate exhibits superior durability, resisting impact and weathering better than Mylar, which is prone to tearing and degradation over time. The choice between Mylar and polycarbonate depends on whether cost-efficiency or long-term durability is the priority in the project.

Choosing the Right Material: Mylar or Polycarbonate

Mylar offers superior reflectivity with up to 98% light reflectance, making it ideal for applications requiring maximum light efficiency, such as grow rooms and lighting fixtures. Polycarbonate, while less reflective, provides excellent diffusion properties and greater impact resistance, suitable for protective covers and diffuse lighting solutions. Choosing between Mylar and polycarbonate depends on whether high reflectivity or durability with light diffusion is the priority for your project.

Mylar Reflection vs Polycarbonate Diffusion Infographic

materialdif.com

materialdif.com