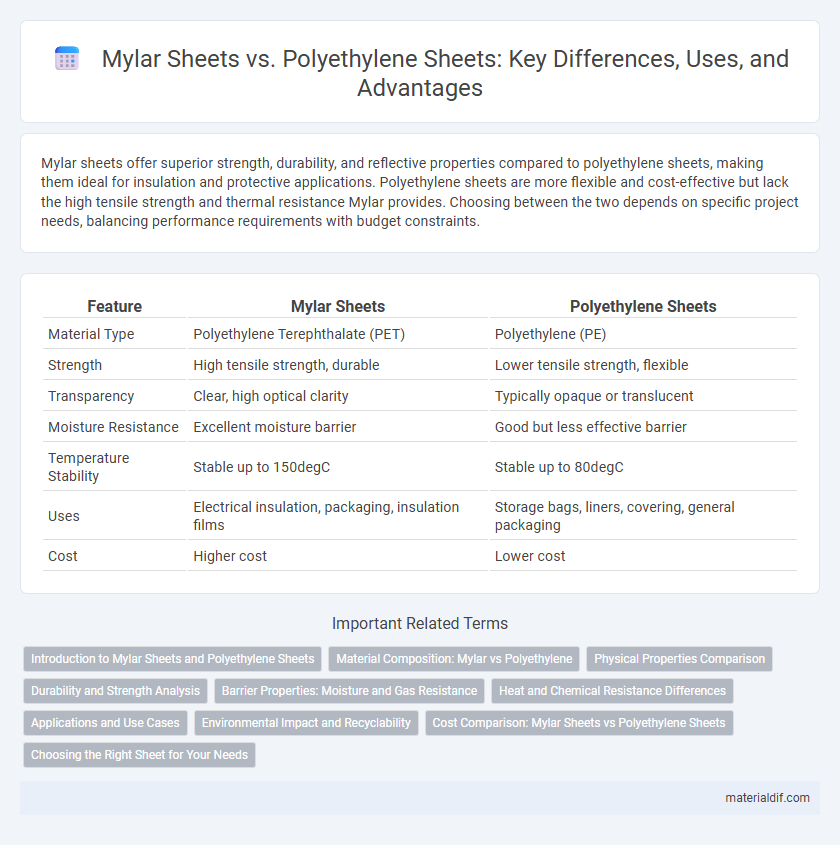

Mylar sheets offer superior strength, durability, and reflective properties compared to polyethylene sheets, making them ideal for insulation and protective applications. Polyethylene sheets are more flexible and cost-effective but lack the high tensile strength and thermal resistance Mylar provides. Choosing between the two depends on specific project needs, balancing performance requirements with budget constraints.

Table of Comparison

| Feature | Mylar Sheets | Polyethylene Sheets |

|---|---|---|

| Material Type | Polyethylene Terephthalate (PET) | Polyethylene (PE) |

| Strength | High tensile strength, durable | Lower tensile strength, flexible |

| Transparency | Clear, high optical clarity | Typically opaque or translucent |

| Moisture Resistance | Excellent moisture barrier | Good but less effective barrier |

| Temperature Stability | Stable up to 150degC | Stable up to 80degC |

| Uses | Electrical insulation, packaging, insulation films | Storage bags, liners, covering, general packaging |

| Cost | Higher cost | Lower cost |

Introduction to Mylar Sheets and Polyethylene Sheets

Mylar sheets, made from biaxially-oriented polyethylene terephthalate (BoPET), offer exceptional tensile strength, dimensional stability, and resistance to moisture and chemicals, making them ideal for insulation, packaging, and graphic arts applications. Polyethylene sheets, derived from polymerized ethylene, provide flexibility, impact resistance, and excellent chemical resistance, commonly used in packaging, protective covers, and liners. While Mylar excels in clarity and durability under stress, polyethylene is preferred for applications requiring cushioning and moisture barrier properties.

Material Composition: Mylar vs Polyethylene

Mylar sheets are made from stretched polyethylene terephthalate (PET) film, known for its high tensile strength, clarity, and chemical stability, making it ideal for insulation and reflective applications. In contrast, polyethylene sheets consist of thermoplastic polymers made from ethylene monomers, offering flexibility, moisture resistance, and chemical inertness, commonly used in packaging and protective coverings. The distinct molecular structures of Mylar's PET and polyethylene result in differing physical properties and performance suited to specific industrial and commercial uses.

Physical Properties Comparison

Mylar sheets exhibit superior tensile strength and dimensional stability compared to polyethylene sheets, making them ideal for applications requiring durability and resistance to stretching. Mylar also offers higher clarity and better resistance to moisture and chemicals, while polyethylene sheets are more flexible and have greater impact resistance. Both materials serve diverse uses, but Mylar's enhanced thermal stability and electrical insulation properties distinguish it in industrial and electronic contexts.

Durability and Strength Analysis

Mylar sheets exhibit superior durability and tensile strength compared to polyethylene sheets, making them more resistant to tearing and punctures in demanding applications. The polyester composition of Mylar provides enhanced dimensional stability and chemical resistance, whereas polyethylene sheets tend to degrade faster under UV exposure and mechanical stress. Mylar's high tensile strength typically ranges between 17,000 and 23,000 psi, significantly outperforming polyethylene's tensile strength of around 3,000 to 5,000 psi, ensuring longer-lasting performance in industrial and protective uses.

Barrier Properties: Moisture and Gas Resistance

Mylar sheets exhibit superior barrier properties compared to polyethylene sheets, offering enhanced resistance to moisture and gases such as oxygen and carbon dioxide. The polyethylene sheets have higher permeability rates, making them less effective for applications requiring airtight seals and long-term preservation. Mylar's polyester composition provides a dense molecular structure, significantly reducing the transmission of moisture vapor and gases, crucial for food packaging and electronic insulation.

Heat and Chemical Resistance Differences

Mylar sheets exhibit superior heat resistance, withstanding temperatures up to 150degC, compared to polyethylene sheets that typically endure only around 80degC. Chemically, Mylar is highly resistant to oils, greases, and most solvents, whereas polyethylene is more prone to degradation when exposed to strong chemicals and solvents. These differences make Mylar sheets ideal for high-temperature and chemically aggressive environments, while polyethylene sheets are better suited for lower heat and less demanding chemical applications.

Applications and Use Cases

Mylar sheets, made from biaxially-oriented polyethylene terephthalate (BoPET), excel in applications requiring high tensile strength, chemical stability, and excellent electrical insulation, making them ideal for electrical insulation, packaging, and reflective insulation in HVAC systems. Polyethylene sheets, derived from low or high-density polyethylene, are preferred in applications demanding flexibility, moisture barriers, and cost-effectiveness, such as agricultural mulching, protective covers, and food packaging. The choice between Mylar and polyethylene sheets depends on specific use cases; Mylar's superior durability suits industrial and aerospace needs, while polyethylene's versatility meets everyday protective and packaging requirements.

Environmental Impact and Recyclability

Mylar sheets, made from biaxially-oriented polyethylene terephthalate (BoPET), have a higher environmental impact compared to polyethylene sheets due to their energy-intensive production process but offer superior recyclability through specialized PET recycling programs. Polyethylene sheets, commonly made from low-density polyethylene (LDPE) or high-density polyethylene (HDPE), are widely recyclable in municipal recycling streams, although their production involves fossil fuels and contributes to plastic pollution. Choosing Mylar sheets supports projects requiring durability and recyclability in specialized facilities, while polyethylene sheets offer broader recycling accessibility with lower processing emissions.

Cost Comparison: Mylar Sheets vs Polyethylene Sheets

Mylar sheets generally cost more than polyethylene sheets due to their superior tensile strength, chemical resistance, and durability. Polyethylene sheets offer a budget-friendly option for applications requiring basic moisture barriers or lightweight packaging. When comparing cost-effectiveness, Mylar's higher upfront expense is often justified by its extended lifespan and enhanced protective qualities.

Choosing the Right Sheet for Your Needs

Mylar sheets offer superior tensile strength, excellent dimensional stability, and high resistance to moisture and chemicals, making them ideal for applications requiring durability and clarity. Polyethylene sheets provide greater flexibility, impact resistance, and cost-effectiveness, suitable for protective coverings and packaging where softness and affordability are priorities. Selecting the right sheet depends on factors like environmental exposure, mechanical stress, and budget constraints, ensuring optimal performance and longevity.

Mylar Sheets vs Polyethylene Sheets Infographic

materialdif.com

materialdif.com