Metallized Mylar features a thin metallic coating that enhances its reflective properties and provides excellent barrier protection against moisture and gases. Laminated Mylar combines multiple layers of film, improving durability, puncture resistance, and overall strength while maintaining flexibility. Choosing between metallized and laminated Mylar depends on the specific pet packaging requirements, such as the desired shelf life and handling conditions.

Table of Comparison

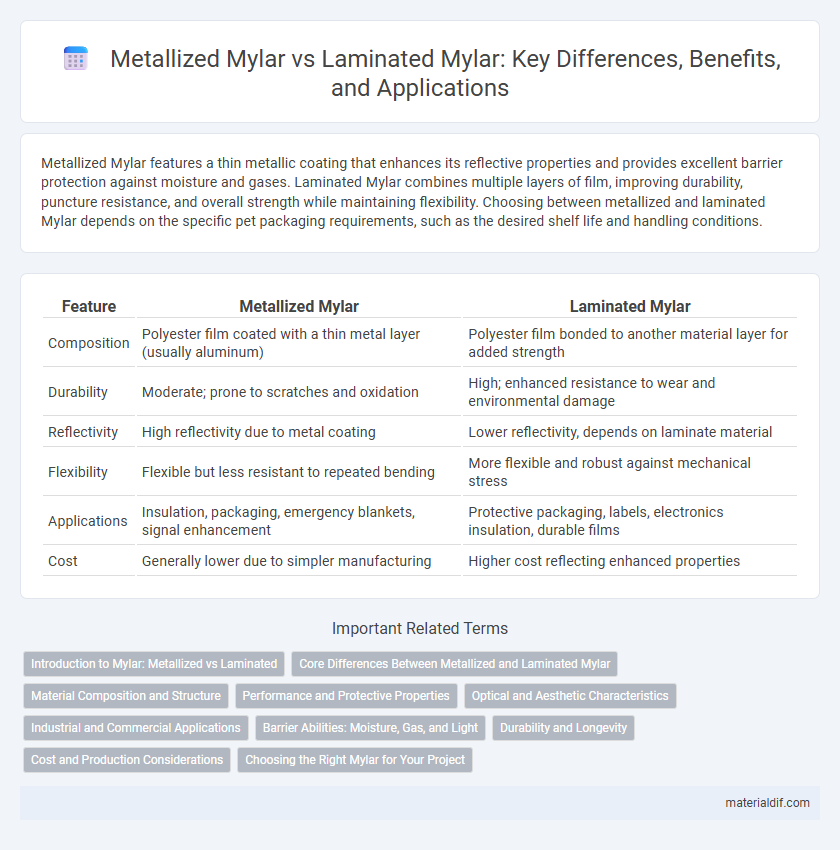

| Feature | Metallized Mylar | Laminated Mylar |

|---|---|---|

| Composition | Polyester film coated with a thin metal layer (usually aluminum) | Polyester film bonded to another material layer for added strength |

| Durability | Moderate; prone to scratches and oxidation | High; enhanced resistance to wear and environmental damage |

| Reflectivity | High reflectivity due to metal coating | Lower reflectivity, depends on laminate material |

| Flexibility | Flexible but less resistant to repeated bending | More flexible and robust against mechanical stress |

| Applications | Insulation, packaging, emergency blankets, signal enhancement | Protective packaging, labels, electronics insulation, durable films |

| Cost | Generally lower due to simpler manufacturing | Higher cost reflecting enhanced properties |

Introduction to Mylar: Metallized vs Laminated

Metallized Mylar features a thin metal coating, typically aluminum, that enhances reflectivity, moisture resistance, and barrier properties, making it ideal for insulation and packaging applications. Laminated Mylar consists of multiple layers bonded together, offering increased durability, tear resistance, and dimensional stability for use in flexible packaging and protective coverings. Both types provide unique benefits depending on their structural design, with metallized variants emphasizing reflective qualities and laminated versions focusing on strength and versatility.

Core Differences Between Metallized and Laminated Mylar

Metallized Mylar features a thin layer of metal, usually aluminum, vacuum-deposited onto the film, providing enhanced reflectivity, improved barrier properties against moisture and gases, and increased electrical conductivity. Laminated Mylar involves bonding multiple layers of Mylar film together, often with adhesives or other substrates, to increase tensile strength, durability, and resistance to punctures and tears. Core differences lie in their functional properties: metallized Mylar excels in reflective and barrier applications, while laminated Mylar offers superior mechanical strength and structural integrity.

Material Composition and Structure

Metallized Mylar consists of a polyester film coated with a thin layer of metal, typically aluminum, which enhances its reflective properties and increases its barrier effectiveness against moisture and gases. Laminated Mylar combines multiple layers of polyester films bonded together, sometimes with adhesive layers, to improve strength, durability, and resistance to punctures while maintaining flexibility. The structural difference lies in Metallized Mylar's single metallized surface, whereas Laminated Mylar provides a composite multi-layer system for specialized industrial and packaging applications.

Performance and Protective Properties

Metallized Mylar offers superior reflective properties and enhanced barrier protection against moisture, gases, and light, making it ideal for insulation and packaging applications. Laminated Mylar provides increased durability and puncture resistance through multiple bonded layers, improving mechanical strength and protection against physical damage. Both materials excel in preserving product integrity, but Metallized Mylar prioritizes barrier efficiency while Laminated Mylar enhances structural resilience.

Optical and Aesthetic Characteristics

Metallized Mylar features a reflective surface created by vapor-depositing a thin layer of metal, enhancing its optical clarity and providing a mirror-like finish that excels in light reflection and brightness. Laminated Mylar involves bonding layers of Mylar film to increase durability and offers a smoother, more uniform appearance with reduced glare, making it ideal for applications requiring consistent aesthetics. Both types maintain excellent color retention and surface gloss, but Metallized Mylar's metallic sheen delivers a striking visual impact, while Laminated Mylar provides enhanced surface protection and refined visual smoothness.

Industrial and Commercial Applications

Metallized Mylar offers superior barrier properties and electrical conductivity, making it ideal for industrial applications such as insulation, capacitors, and reflective surfaces in lighting and electronics. Laminated Mylar provides enhanced durability, moisture resistance, and strength, which suits commercial packaging, labeling, and protective coverings for machinery. Both types optimize performance based on specific requirements in temperature resistance, chemical exposure, and mechanical stress in industrial and commercial environments.

Barrier Abilities: Moisture, Gas, and Light

Metallized Mylar offers superior barrier properties against moisture, gases, and light due to its thin metal coating that significantly reduces permeability. Laminated Mylar, constructed by bonding multiple layers, enhances durability and mechanical strength but typically provides slightly lower moisture and gas barrier performance compared to metallized versions. Both types are effective for packaging applications, with metallized Mylar preferred for maximum barrier protection and laminated Mylar chosen when flexibility and toughness are prioritized.

Durability and Longevity

Metallized Mylar features a thin layer of metal, typically aluminum, which enhances its reflective properties but makes it more susceptible to tearing and degradation over time. Laminated Mylar combines multiple layers, increasing its resistance to wear, moisture, and punctures, thereby significantly improving durability and longevity. For applications demanding extended lifespan and high durability, laminated Mylar is generally the superior choice.

Cost and Production Considerations

Metallized Mylar offers a cost-effective solution due to its lightweight aluminum coating process, leading to lower production expenses compared to Laminated Mylar, which involves additional layers that increase manufacturing complexity and material costs. Production of Metallized Mylar benefits from faster processing times and reduced energy consumption, making it ideal for high-volume applications with budget constraints. In contrast, Laminated Mylar provides enhanced durability and moisture resistance but demands higher investment in materials and labor, impacting overall production cost-efficiency.

Choosing the Right Mylar for Your Project

Metallized Mylar offers superior reflective properties and excellent barrier protection against moisture and gases, making it ideal for insulation and packaging applications. Laminated Mylar provides enhanced durability, tear resistance, and added layers for specific functional needs, such as UV protection or printability. Selecting the right Mylar depends on the project's requirements for reflectivity, strength, and environmental resistance, ensuring optimal performance and longevity.

Metallized Mylar vs Laminated Mylar Infographic

materialdif.com

materialdif.com