Mylar windows offer superior flexibility and lightweight properties compared to acrylic windows, making them ideal for lightweight pet enclosure designs. Unlike acrylic, Mylar provides excellent clarity while being less prone to cracking or shattering under impact. Mylar's reflective surface also helps regulate temperature by reflecting heat, enhancing comfort for pets.

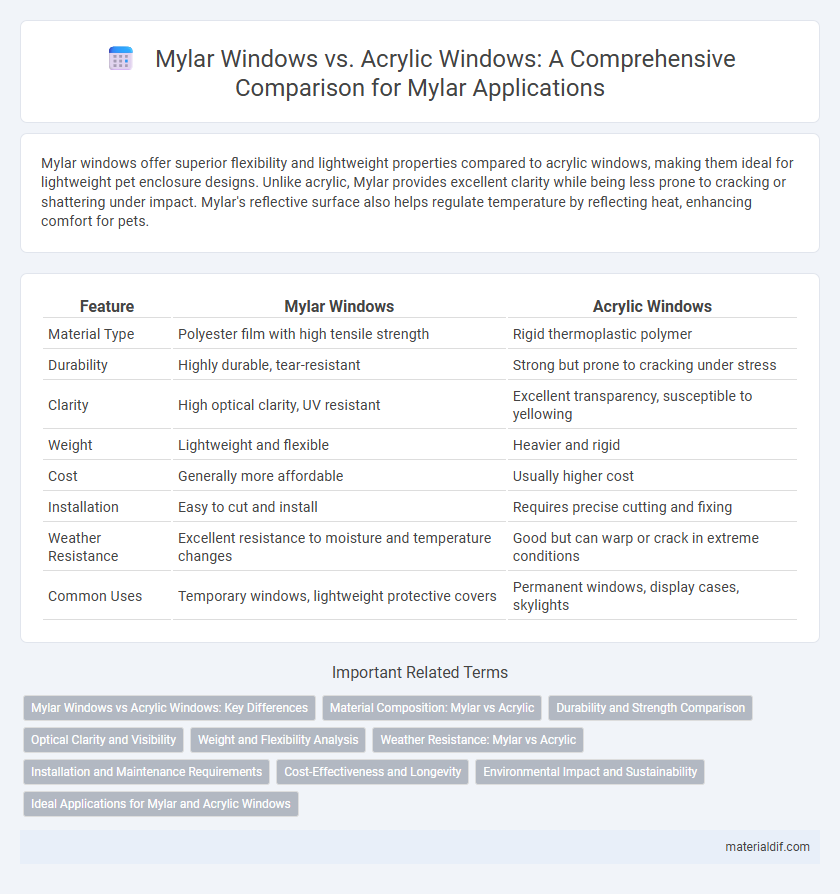

Table of Comparison

| Feature | Mylar Windows | Acrylic Windows |

|---|---|---|

| Material Type | Polyester film with high tensile strength | Rigid thermoplastic polymer |

| Durability | Highly durable, tear-resistant | Strong but prone to cracking under stress |

| Clarity | High optical clarity, UV resistant | Excellent transparency, susceptible to yellowing |

| Weight | Lightweight and flexible | Heavier and rigid |

| Cost | Generally more affordable | Usually higher cost |

| Installation | Easy to cut and install | Requires precise cutting and fixing |

| Weather Resistance | Excellent resistance to moisture and temperature changes | Good but can warp or crack in extreme conditions |

| Common Uses | Temporary windows, lightweight protective covers | Permanent windows, display cases, skylights |

Mylar Windows vs Acrylic Windows: Key Differences

Mylar windows offer superior UV resistance and flexibility compared to acrylic windows, making them ideal for applications requiring durability and clarity under harsh conditions. Acrylic windows provide higher impact resistance and stiffness, which benefits structural stability but may yellow over time due to UV exposure. Choosing between Mylar and acrylic windows depends on prioritizing UV protection and lightweight flexibility versus impact strength and rigidity.

Material Composition: Mylar vs Acrylic

Mylar windows are made from stretched polyethylene terephthalate (PET) film, providing strong tensile strength, excellent clarity, and resistance to moisture and UV light. Acrylic windows consist of polymethyl methacrylate (PMMA), a rigid thermoplastic known for its transparency and weather resistance but with less flexibility compared to Mylar. The key difference in material composition affects durability, flexibility, and suitability for different environmental conditions, with Mylar offering superior resilience in dynamic or flexible applications.

Durability and Strength Comparison

Mylar windows offer superior tensile strength and resistance to tearing compared to acrylic windows, making them highly durable under stress and extreme weather conditions. Acrylic windows, while providing good clarity, are more prone to cracking and scratching over time, reducing their long-term strength. The molecular structure of Mylar enhances impact resistance and flexibility, ensuring better performance in demanding environments.

Optical Clarity and Visibility

Mylar windows offer superior optical clarity compared to acrylic windows due to their high transparency and low haze properties, ensuring unobstructed visibility. Unlike acrylic, Mylar's smooth, non-porous surface resists yellowing and maintains consistent light transmission over time. This makes Mylar an ideal choice for applications requiring long-lasting, clear viewing without distortion or glare.

Weight and Flexibility Analysis

Mylar windows are significantly lighter than acrylic windows, with Mylar films typically weighing less than one-tenth the density of acrylic sheets, enhancing ease of installation and reducing structural load. The flexibility of Mylar allows it to bend and conform to curved surfaces without cracking, unlike acrylic which is rigid and prone to fracture under stress. This combination of low weight and high flexibility makes Mylar ideal for applications requiring lightweight, durable window materials in aerospace, aviation, and specialized architectural projects.

Weather Resistance: Mylar vs Acrylic

Mylar windows exhibit superior weather resistance compared to acrylic windows due to their enhanced UV blocking properties and moisture barrier capabilities, which prevent yellowing and degradation over time. Acrylic windows, while durable, are more susceptible to scratches and can become brittle with prolonged exposure to harsh sunlight and fluctuating temperatures. This makes Mylar an ideal choice for long-term outdoor applications requiring consistent clarity and protection against environmental elements.

Installation and Maintenance Requirements

Mylar windows offer lightweight installation and flexibility, making them easier to handle and secure compared to rigid acrylic windows that often require precise fitting and specialized mounting hardware. Maintenance of Mylar windows involves simple cleaning with mild soap and water, whereas acrylic windows can collect scratches and may need polishing or replacement over time. The durability and ease of upkeep of Mylar make it a cost-effective choice for applications requiring frequent cleaning and quick installation.

Cost-Effectiveness and Longevity

Mylar windows offer superior cost-effectiveness compared to acrylic windows due to their lower initial price and enhanced durability against UV radiation and weathering. Acrylic windows may incur higher maintenance and replacement costs over time because they are more prone to yellowing and cracking under prolonged exposure. Choosing Mylar windows ensures a longer lifespan and reduced long-term expenses, making them ideal for budget-conscious applications requiring sturdy, clear glazing.

Environmental Impact and Sustainability

Mylar windows offer superior environmental benefits due to their lightweight, recyclable polyester film composition, reducing carbon footprint compared to acrylic's petroleum-based manufacturing. Acrylic windows, while durable, involve energy-intensive production and generate more non-biodegradable waste, impacting landfill volume negatively. Choosing Mylar supports sustainability efforts by promoting reduced resource use and enhanced recyclability in window materials.

Ideal Applications for Mylar and Acrylic Windows

Mylar windows are ideal for applications requiring high tensile strength, chemical resistance, and excellent barrier properties, making them perfect for industrial packaging and protective covers. Acrylic windows excel in clarity, impact resistance, and weather durability, commonly used in retail displays, skylights, and protective barriers. Choosing between Mylar and acrylic depends on whether flexibility and barrier performance or optical clarity and rigid protection are the primary needs.

Mylar Windows vs Acrylic Windows Infographic

materialdif.com

materialdif.com