Mylar sheeting offers superior tensile strength and excellent moisture barrier properties compared to polyethylene sheeting, making it ideal for long-term storage and insulation. Unlike polyethylene, Mylar provides enhanced reflectivity and durability, which helps maintain temperature control and resist UV damage. Its lightweight yet sturdy composition ensures better protection for sensitive items, especially in pet care environments where contamination and wear are concerns.

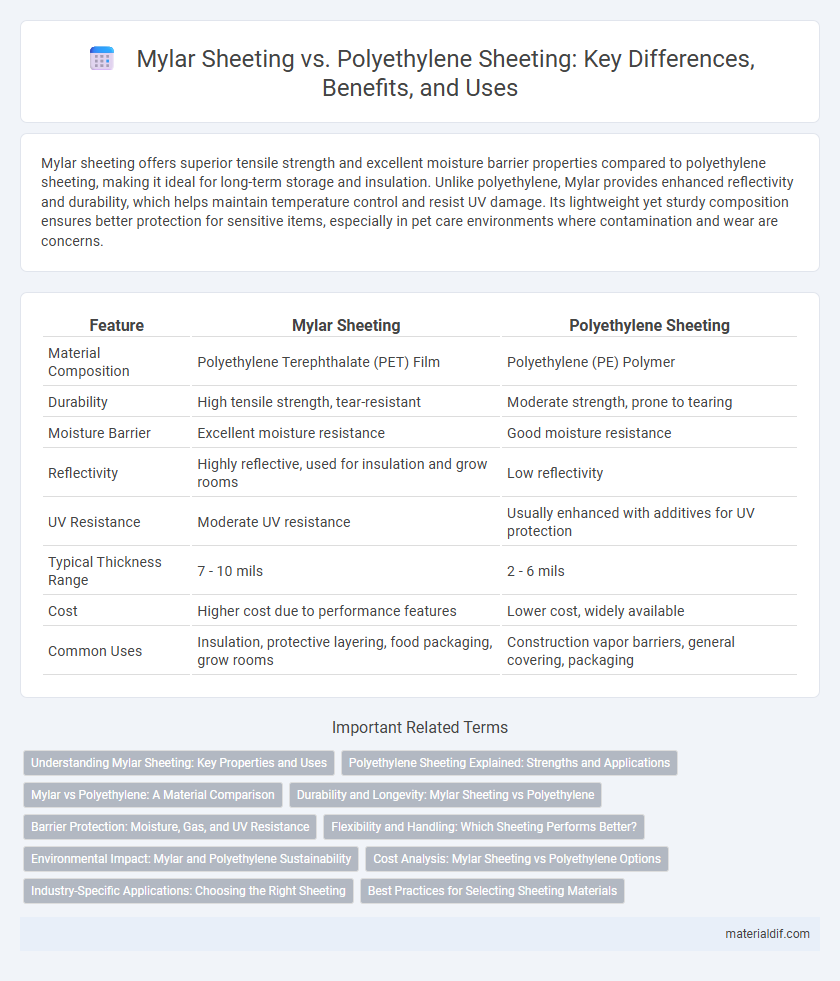

Table of Comparison

| Feature | Mylar Sheeting | Polyethylene Sheeting |

|---|---|---|

| Material Composition | Polyethylene Terephthalate (PET) Film | Polyethylene (PE) Polymer |

| Durability | High tensile strength, tear-resistant | Moderate strength, prone to tearing |

| Moisture Barrier | Excellent moisture resistance | Good moisture resistance |

| Reflectivity | Highly reflective, used for insulation and grow rooms | Low reflectivity |

| UV Resistance | Moderate UV resistance | Usually enhanced with additives for UV protection |

| Typical Thickness Range | 7 - 10 mils | 2 - 6 mils |

| Cost | Higher cost due to performance features | Lower cost, widely available |

| Common Uses | Insulation, protective layering, food packaging, grow rooms | Construction vapor barriers, general covering, packaging |

Understanding Mylar Sheeting: Key Properties and Uses

Mylar sheeting, made from biaxially-oriented polyethylene terephthalate (BoPET), offers superior tensile strength, dimensional stability, and chemical resistance compared to polyethylene sheeting, making it ideal for insulation, reflective surfaces, and packaging. Its high tensile strength and low permeability to gases and moisture enable extended product protection and enhanced insulation performance in HVAC and agricultural applications. Unlike polyethylene, Mylar's reflective properties and resistance to stretching under tension make it preferred for emergency blankets, spacecraft insulation, and high-quality graphic arts.

Polyethylene Sheeting Explained: Strengths and Applications

Polyethylene sheeting is a versatile plastic material known for its flexibility, chemical resistance, and cost-effectiveness, making it ideal for agricultural covers, vapor barriers, and construction applications. Its lightweight nature and moisture resistance enable effective protection against environmental elements, while its wide range of thicknesses allows customization for durability and strength. Unlike Mylar, polyethylene sheeting lacks reflective properties but excels in impact resistance and affordability for large-scale industrial uses.

Mylar vs Polyethylene: A Material Comparison

Mylar sheeting, made from stretched polyethylene terephthalate (PET), offers superior tensile strength, chemical resistance, and thermal stability compared to polyethylene sheeting, which is typically less durable and more prone to punctures and chemical degradation. Mylar's reflective surface enhances insulation and light reflection, making it ideal for applications like emergency blankets and insulation barriers, whereas polyethylene sheeting is more commonly used for temporary coverings and moisture barriers due to its lower cost and flexibility. The molecular structure of Mylar provides enhanced dimensional stability and UV resistance, outperforming polyethylene in long-term outdoor and industrial uses.

Durability and Longevity: Mylar Sheeting vs Polyethylene

Mylar sheeting demonstrates superior durability and longevity compared to polyethylene sheeting due to its polyester composition, which provides enhanced resistance to tearing, moisture, and ultraviolet (UV) degradation. While polyethylene sheeting is more prone to wear and environmental damage over time, Mylar maintains its integrity under harsh conditions, making it ideal for long-term applications. The high tensile strength and stability of Mylar sheeting ensure prolonged performance in both indoor and outdoor environments.

Barrier Protection: Moisture, Gas, and UV Resistance

Mylar sheeting offers superior barrier protection compared to polyethylene sheeting, effectively blocking moisture, gases, and UV radiation due to its metallized polyester composition. Its low permeability to oxygen and water vapor enhances preservation and insulation applications where airtight and moisture-resistant seals are critical. Polyethylene sheeting provides basic moisture resistance but lacks the advanced gas and UV barrier properties essential for long-term protection against environmental factors.

Flexibility and Handling: Which Sheeting Performs Better?

Mylar sheeting offers superior flexibility and durability compared to polyethylene sheeting, making it easier to handle in various applications. Its tensile strength and resistance to stretching allow for smooth wrapping and fewer creases, enhancing performance. Polyethylene sheeting is more prone to tearing and less flexible, which can complicate installation and reduce long-term reliability.

Environmental Impact: Mylar and Polyethylene Sustainability

Mylar sheeting, made from biaxially-oriented polyethylene terephthalate (BoPET), offers superior durability and recyclability compared to polyethylene sheeting, which is derived from non-biodegradable low-density or high-density polyethylene. Mylar's high tensile strength and resistance to moisture reduce the need for frequent replacement, thereby minimizing waste generation. Polyethylene sheeting, while cheaper, contributes more significantly to environmental pollution due to slower degradation rates and limited recycling infrastructure.

Cost Analysis: Mylar Sheeting vs Polyethylene Options

Mylar sheeting generally incurs higher upfront costs compared to polyethylene sheeting due to its enhanced durability and reflective properties, making it a preferred investment for long-term applications. Polyethylene sheeting remains more budget-friendly, especially for large-scale projects requiring extensive coverage with minimal initial expenditure. Evaluating total cost of ownership reveals Mylar's resistance to environmental degradation can offset its price over time through reduced replacement and maintenance expenses.

Industry-Specific Applications: Choosing the Right Sheeting

Mylar sheeting offers superior tensile strength, chemical resistance, and dimensional stability, making it ideal for electronics, aerospace, and packaging industries that demand durability and precision. Polyethylene sheeting provides flexibility and cost-effectiveness, suited for construction, agriculture, and temporary protective coverings where moisture resistance and affordability are priorities. Industry-specific application needs dictate the optimal choice between Mylar and polyethylene sheeting to ensure performance and cost efficiency.

Best Practices for Selecting Sheeting Materials

Mylar sheeting offers superior tensile strength and moisture resistance compared to polyethylene sheeting, making it ideal for applications requiring durability and barrier protection. When selecting sheeting materials, prioritize environmental conditions, intended use duration, and budget constraints to balance performance with cost-effectiveness. For long-term outdoor use or chemical resistance, Mylar sheeting is the optimal choice due to its reflective properties and resistance to UV degradation.

Mylar Sheeting vs Polyethylene Sheeting Infographic

materialdif.com

materialdif.com