Mylar overlays offer a flexible, cost-effective solution with good light transmission, making them ideal for temporary or low-impact uses. Polycarbonate overlays provide superior durability and impact resistance, ensuring long-lasting protection against scratches and environmental damage. Choosing between Mylar and polycarbonate depends on the required balance of affordability and strength for your specific pet project.

Table of Comparison

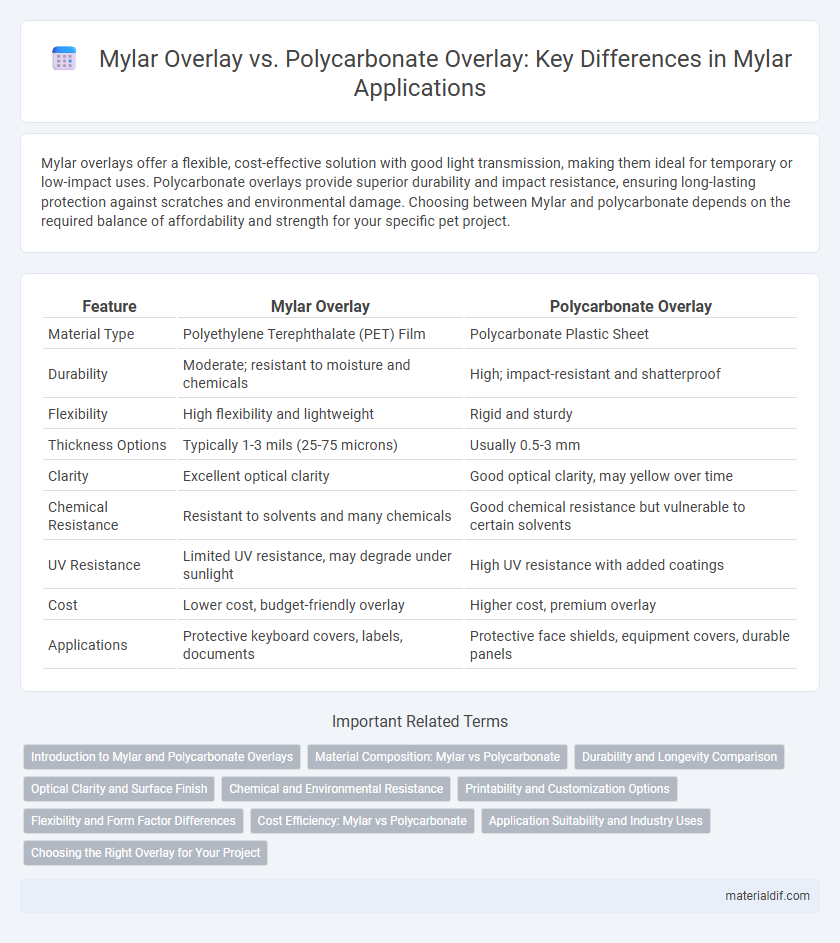

| Feature | Mylar Overlay | Polycarbonate Overlay |

|---|---|---|

| Material Type | Polyethylene Terephthalate (PET) Film | Polycarbonate Plastic Sheet |

| Durability | Moderate; resistant to moisture and chemicals | High; impact-resistant and shatterproof |

| Flexibility | High flexibility and lightweight | Rigid and sturdy |

| Thickness Options | Typically 1-3 mils (25-75 microns) | Usually 0.5-3 mm |

| Clarity | Excellent optical clarity | Good optical clarity, may yellow over time |

| Chemical Resistance | Resistant to solvents and many chemicals | Good chemical resistance but vulnerable to certain solvents |

| UV Resistance | Limited UV resistance, may degrade under sunlight | High UV resistance with added coatings |

| Cost | Lower cost, budget-friendly overlay | Higher cost, premium overlay |

| Applications | Protective keyboard covers, labels, documents | Protective face shields, equipment covers, durable panels |

Introduction to Mylar and Polycarbonate Overlays

Mylar overlays offer a lightweight, flexible protective layer made from polyethylene terephthalate (PET) film, known for its clarity and durability in various applications. Polycarbonate overlays provide a more rigid, impact-resistant barrier created from a durable thermoplastic polymer, excelling in environments requiring enhanced strength and scratch resistance. Both materials serve as effective protective covers, with Mylar favored for its thinness and transparency, while polycarbonate is preferred for heavy-duty protection and longevity.

Material Composition: Mylar vs Polycarbonate

Mylar overlay consists of biaxially-oriented polyethylene terephthalate (BoPET), known for its high tensile strength, chemical stability, and excellent dimensional stability. Polycarbonate overlay is made from a durable thermoplastic polymer characterized by impact resistance, optical clarity, and heat resistance. The distinct molecular structures of Mylar and polycarbonate affect their flexibility, durability, and environmental resistance in overlay applications.

Durability and Longevity Comparison

Mylar overlays offer excellent chemical resistance and flexibility, making them highly durable for various applications, but they may be prone to scratching over extended use. Polycarbonate overlays outperform Mylar in impact resistance and scratch hardness, providing superior longevity in harsher environments. The choice between Mylar and polycarbonate overlays depends on the required balance between cost-effectiveness and enhanced durability for long-term projects.

Optical Clarity and Surface Finish

Mylar overlays provide superior optical clarity due to their high transparency and low haze properties, making them ideal for applications requiring precise visual performance. Polycarbonate overlays, while offering excellent impact resistance, typically exhibit slightly lower optical clarity and may have a glossier surface finish that can increase glare. The choice between Mylar and polycarbonate overlays depends on the balance needed between clear visibility and durability in the specific application.

Chemical and Environmental Resistance

Mylar overlay offers superior chemical resistance, effectively withstanding acids, alkalis, and solvents, making it ideal for harsh environments. Polycarbonate overlay provides excellent impact resistance but is more susceptible to chemical degradation from organic solvents and UV exposure. Environmental durability of Mylar ensures longer lifespan in corrosive or chemically aggressive settings compared to polycarbonate, which may yellow or crack over time.

Printability and Customization Options

Mylar overlays offer superior printability due to their smooth, non-porous surface, enabling crisp, high-resolution graphics ideal for detailed designs. Polycarbonate overlays provide enhanced customization flexibility with options for embossing, texturing, and varying thicknesses, making them suitable for tactile interfaces and durable applications. Choosing between Mylar and polycarbonate depends on the balance between print quality and the need for physical customization in the final product.

Flexibility and Form Factor Differences

Mylar overlays offer superior flexibility and thinner form factors compared to polycarbonate overlays, making them ideal for applications requiring lightweight and bendable materials. Polycarbonate overlays provide enhanced rigidity and impact resistance but are generally thicker and less flexible, which can limit design versatility. Choosing between Mylar and polycarbonate depends on the need for flexibility versus durability in specific product designs.

Cost Efficiency: Mylar vs Polycarbonate

Mylar overlays offer superior cost efficiency compared to polycarbonate overlays due to their lower material and production expenses, making them ideal for budget-sensitive projects. Polycarbonate, while more durable and impact-resistant, typically incurs higher upfront costs and increased maintenance over time. Choosing Mylar ensures affordable protection without significant compromise on performance in applications where extreme toughness is not critical.

Application Suitability and Industry Uses

Mylar overlays are highly suitable for applications requiring flexibility, chemical resistance, and clarity, making them ideal for electrical insulation, solar panels, and packaging industries. Polycarbonate overlays offer superior impact resistance and durability, commonly used in automotive, aerospace, and protective equipment sectors. Choosing between Mylar and polycarbonate depends on specific industry demands such as temperature tolerance, mechanical strength, and clarity requirements.

Choosing the Right Overlay for Your Project

Mylar overlays offer superior flexibility, chemical resistance, and clarity, making them ideal for applications requiring lightweight and durable protection. Polycarbonate overlays provide exceptional impact resistance and UV protection, suited for environments exposed to physical stress and outdoor conditions. Selecting the right overlay depends on project needs such as durability, environmental exposure, and budget considerations.

Mylar Overlay vs Polycarbonate Overlay Infographic

materialdif.com

materialdif.com