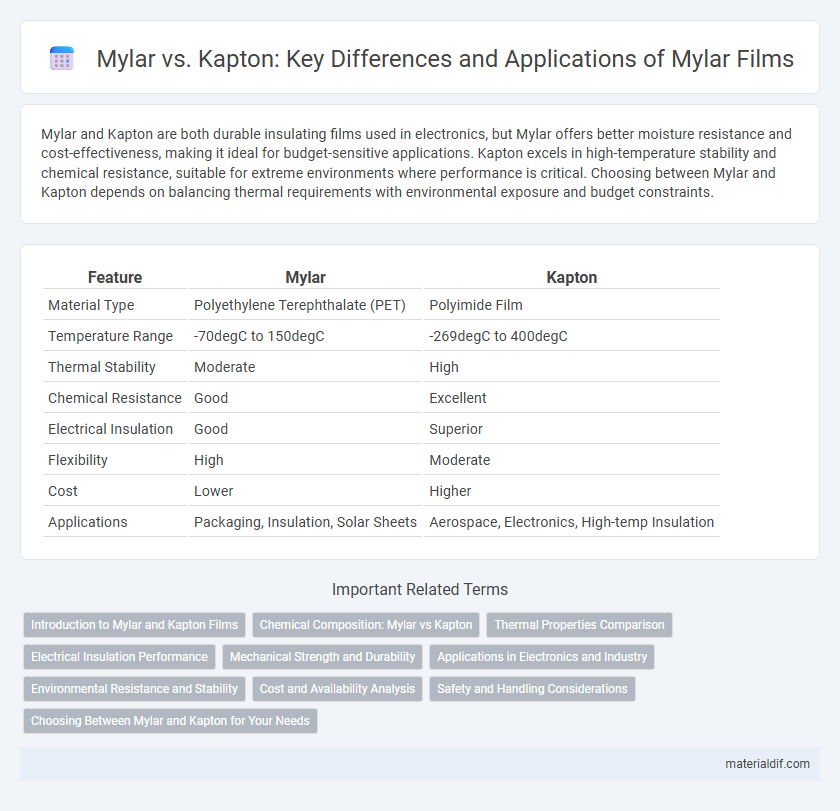

Mylar and Kapton are both durable insulating films used in electronics, but Mylar offers better moisture resistance and cost-effectiveness, making it ideal for budget-sensitive applications. Kapton excels in high-temperature stability and chemical resistance, suitable for extreme environments where performance is critical. Choosing between Mylar and Kapton depends on balancing thermal requirements with environmental exposure and budget constraints.

Table of Comparison

| Feature | Mylar | Kapton |

|---|---|---|

| Material Type | Polyethylene Terephthalate (PET) | Polyimide Film |

| Temperature Range | -70degC to 150degC | -269degC to 400degC |

| Thermal Stability | Moderate | High |

| Chemical Resistance | Good | Excellent |

| Electrical Insulation | Good | Superior |

| Flexibility | High | Moderate |

| Cost | Lower | Higher |

| Applications | Packaging, Insulation, Solar Sheets | Aerospace, Electronics, High-temp Insulation |

Introduction to Mylar and Kapton Films

Mylar is a polyester film known for its excellent tensile strength, chemical stability, and electrical insulation properties, widely used in packaging, insulation, and flexible electronics. Kapton, a polyimide film, offers superior thermal stability and can operate at extreme temperatures up to 400degC, making it ideal for aerospace, electronics, and high-temperature insulation applications. Both films provide distinct advantages: Mylar excels in cost-effective, everyday uses, while Kapton is preferred for high-performance, heat-resistant environments.

Chemical Composition: Mylar vs Kapton

Mylar is a polyester film primarily composed of polyethylene terephthalate (PET), offering excellent dimensional stability and resistance to moisture. Kapton, by contrast, is a polyimide film known for its high thermal stability and chemical resistance due to its aromatic polyimide chemical structure. The differing molecular compositions result in Mylar being more suited for applications requiring flexibility and moisture barrier properties, while Kapton excels in high-temperature environments and electrical insulation.

Thermal Properties Comparison

Mylar exhibits superior thermal stability with a continuous use temperature of around 150degC, whereas Kapton withstands extreme temperatures up to 400degC without degradation. The thermal conductivity of Mylar is lower, making it a better insulator compared to Kapton's higher conductivity suited for heat dissipation applications. Mylar's thermal expansion is moderate, offering dimensional stability in standard conditions, while Kapton maintains exceptional dimensional stability across wide temperature variations.

Electrical Insulation Performance

Mylar exhibits superior electrical insulation performance compared to Kapton, thanks to its high dielectric strength typically ranging from 1500 to 7000 volts per mil. This polyester film maintains excellent insulation properties under varying temperatures and humidity levels, making it ideal for electronics and electrical applications. While Kapton offers excellent thermal stability, Mylar's consistent dielectric reliability and moisture resistance often provide more effective electrical insulation in standard operating conditions.

Mechanical Strength and Durability

Mylar exhibits high tensile strength with excellent resistance to tearing and stretching, making it a durable option for various applications. Kapton surpasses Mylar in thermal stability, maintaining mechanical strength at extreme temperatures from -269degC to 400degC without degradation. The superior mechanical durability of Kapton in harsh environments contrasts with Mylar's strong performance under standard conditions, highlighting Kapton's advantage in high-temperature and chemically aggressive settings.

Applications in Electronics and Industry

Mylar excels in electronics and industry due to its high tensile strength, excellent electrical insulation, and resistance to moisture, making it ideal for capacitor films, flexible printed circuits, and insulation tapes. Kapton stands out for its exceptional thermal stability and chemical resistance, which are crucial in high-temperature environments like aerospace electronics, flexible heaters, and insulating films for circuit boards. Both materials serve critical roles, with Mylar favored for cost-effective insulation and flexibility, while Kapton is chosen for durability under extreme thermal and chemical conditions.

Environmental Resistance and Stability

Mylar exhibits superior environmental resistance with excellent moisture barrier properties and UV stability, making it ideal for outdoor and humid conditions. Kapton offers exceptional thermal stability, maintaining performance across extreme temperature ranges from -269degC to 400degC, but is less resistant to moisture and UV exposure than Mylar. The choice between Mylar and Kapton depends on the specific environmental stressors, where Mylar favors moisture and UV resistance, while Kapton excels in high-temperature stability.

Cost and Availability Analysis

Mylar offers a more cost-effective solution compared to Kapton, with prices significantly lower due to its widespread availability and simpler manufacturing process. Kapton's higher cost stems from its superior thermal stability and specialized polyimide composition, which are beneficial in high-performance applications but limit its accessibility. The abundant production and distribution of Mylar make it a preferred choice for budget-sensitive projects requiring reliable insulating materials.

Safety and Handling Considerations

Mylar and Kapton differ significantly in safety and handling considerations due to their chemical and thermal properties. Mylar, made from biaxially-oriented polyethylene terephthalate (BoPET), is non-toxic, relatively stable, and safe to handle under normal conditions, but it can release harmful fumes if exposed to high temperatures or flames. Kapton, a polyimide film, offers superior thermal resistance up to 400degC and excellent electrical insulation but requires caution as its decomposition at extreme temperatures may produce toxic gases, necessitating proper ventilation and protective equipment during processing.

Choosing Between Mylar and Kapton for Your Needs

Mylar offers excellent tensile strength, chemical stability, and cost-effectiveness, making it ideal for applications requiring high durability and electrical insulation at moderate temperatures up to 150degC. Kapton surpasses Mylar in thermal resistance, performing reliably in extreme temperatures up to 400degC, which suits aerospace, electronics, and high-temperature environments. Selecting between Mylar and Kapton depends on the thermal requirements, budget constraints, and environmental exposure of your specific project.

Mylar vs Kapton Infographic

materialdif.com

materialdif.com