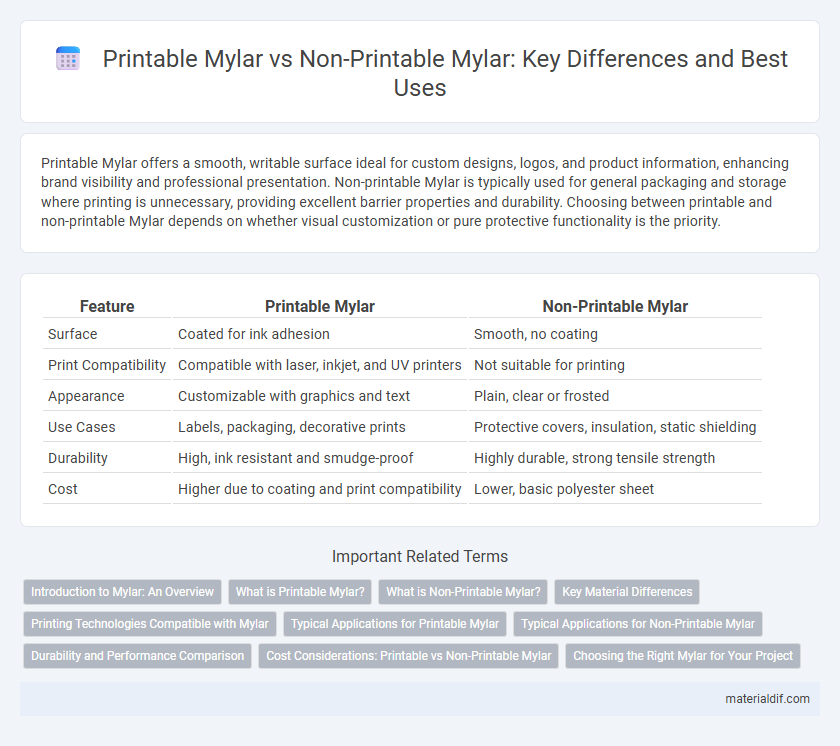

Printable Mylar offers a smooth, writable surface ideal for custom designs, logos, and product information, enhancing brand visibility and professional presentation. Non-printable Mylar is typically used for general packaging and storage where printing is unnecessary, providing excellent barrier properties and durability. Choosing between printable and non-printable Mylar depends on whether visual customization or pure protective functionality is the priority.

Table of Comparison

| Feature | Printable Mylar | Non-Printable Mylar |

|---|---|---|

| Surface | Coated for ink adhesion | Smooth, no coating |

| Print Compatibility | Compatible with laser, inkjet, and UV printers | Not suitable for printing |

| Appearance | Customizable with graphics and text | Plain, clear or frosted |

| Use Cases | Labels, packaging, decorative prints | Protective covers, insulation, static shielding |

| Durability | High, ink resistant and smudge-proof | Highly durable, strong tensile strength |

| Cost | Higher due to coating and print compatibility | Lower, basic polyester sheet |

Introduction to Mylar: An Overview

Mylar is a versatile polyester film known for its durability, chemical resistance, and excellent clarity, widely used in packaging, insulation, and graphic applications. Printable Mylar features a specially coated surface that allows for high-quality ink adhesion, making it ideal for labels, banners, and decorative prints. Non-printable Mylar lacks this coating, providing superior strength and barrier properties for industrial uses such as insulation, protective covers, and flexible electronics.

What is Printable Mylar?

Printable Mylar is a specially coated polyester film designed to accept inks and dyes, allowing high-quality printing for labels, packaging, and decorative applications. This coating enhances adhesion and color vibrancy, making Printable Mylar ideal for digital and screen printing processes. Non-printable Mylar lacks this coating, limiting its use to protective or insulating purposes rather than graphic display.

What is Non-Printable Mylar?

Non-printable Mylar is a polyester film that lacks the surface coating required for ink adhesion, making it unsuitable for direct printing applications. This type of Mylar is commonly used in packaging, insulation, and protective overlays where printing is unnecessary. Its smooth, inert surface provides excellent durability, moisture resistance, and dimensional stability.

Key Material Differences

Printable Mylar features a specially coated surface that enhances ink adhesion, allowing for high-quality graphic printing and vibrant color reproduction, unlike non-printable Mylar which lacks this coating and is primarily used for protective or insulating purposes. The printable variant maintains the core chemical resistance and durability of traditional Mylar but also offers superior print compatibility, making it ideal for labels, signage, and packaging applications. Non-printable Mylar retains a smooth, clear, and glossy finish optimized for optical clarity and barrier properties without the added print receptive layer.

Printing Technologies Compatible with Mylar

Printable Mylar is specially coated to absorb inks from printing technologies such as UV inkjet, solvent inkjet, and screen printing, ensuring high-resolution images and vibrant colors. Non-printable Mylar lacks this coating, making it incompatible with standard ink absorption and limiting its use to applications like lamination or protective coverings. Choosing the right Mylar type depends on the printing technology employed, with printable variants optimized for precise ink adhesion and durability.

Typical Applications for Printable Mylar

Printable Mylar is widely used in applications requiring high-quality, durable graphics such as packaging labels, banners, and name tags due to its smooth surface that supports various printing techniques like screen printing and digital inkjet. Its ability to hold vibrant colors and resist smudging makes it ideal for promotional graphics and product labeling where visual appeal and durability are critical. Non-printable Mylar, lacking the printable coating, is typically used for insulation, protective covers, and barrier films where printability is not a requirement.

Typical Applications for Non-Printable Mylar

Non-printable Mylar is commonly used in applications requiring durability and chemical resistance, such as insulation, protective covers, and packaging materials. Its non-porous surface ensures moisture and gas barrier properties ideal for food storage and industrial laminates. This version of Mylar also serves in electrical insulation, capacitor films, and solar panel back sheets where printing capabilities are unnecessary.

Durability and Performance Comparison

Printable Mylar offers superior performance in high-quality printing applications due to its specially coated surface that enhances ink adhesion and color vibrancy, making it ideal for detailed graphics and labels. Non-printable Mylar, while equally durable with excellent tear resistance and dimensional stability, lacks the coated surface, resulting in poor ink retention and limited use in visual display contexts. Both types provide robust durability, including moisture and chemical resistance, but printable Mylar excels in applications requiring vibrant, long-lasting printed designs.

Cost Considerations: Printable vs Non-Printable Mylar

Printable Mylar typically incurs higher costs due to the specialized coatings required for ink adhesion, making it suitable for high-quality labels and custom prints. Non-printable Mylar is generally more affordable, ideal for packaging and insulation where printing is unnecessary. Cost efficiency depends on project needs, with printable variants justifying expense through enhanced branding and design capabilities.

Choosing the Right Mylar for Your Project

Printable Mylar features a specially coated surface that allows for high-quality ink adhesion, making it ideal for custom designs, labels, and signage requiring precise color output and durability. Non-printable Mylar, while lacking a printable coating, offers superior clarity and strength, making it suitable for protective covers, insulation, and applications prioritizing resilience over graphic detail. Selecting the right Mylar depends on the project's need for visual customization versus physical performance, where printable options enhance graphic presentation and non-printable options provide structural integrity.

Printable Mylar vs Non-Printable Mylar Infographic

materialdif.com

materialdif.com