Glassine offers a smooth, semi-transparent texture that is acid-free and resistant to air and moisture, making it suitable for short-term storage of delicate collectibles. Mylar provides a stronger, more durable barrier with superior clarity and archival-quality protection, ideal for long-term preservation of valuable items. Choosing between Glassine and Mylar depends on the level of protection needed and the desired longevity of the stored materials.

Table of Comparison

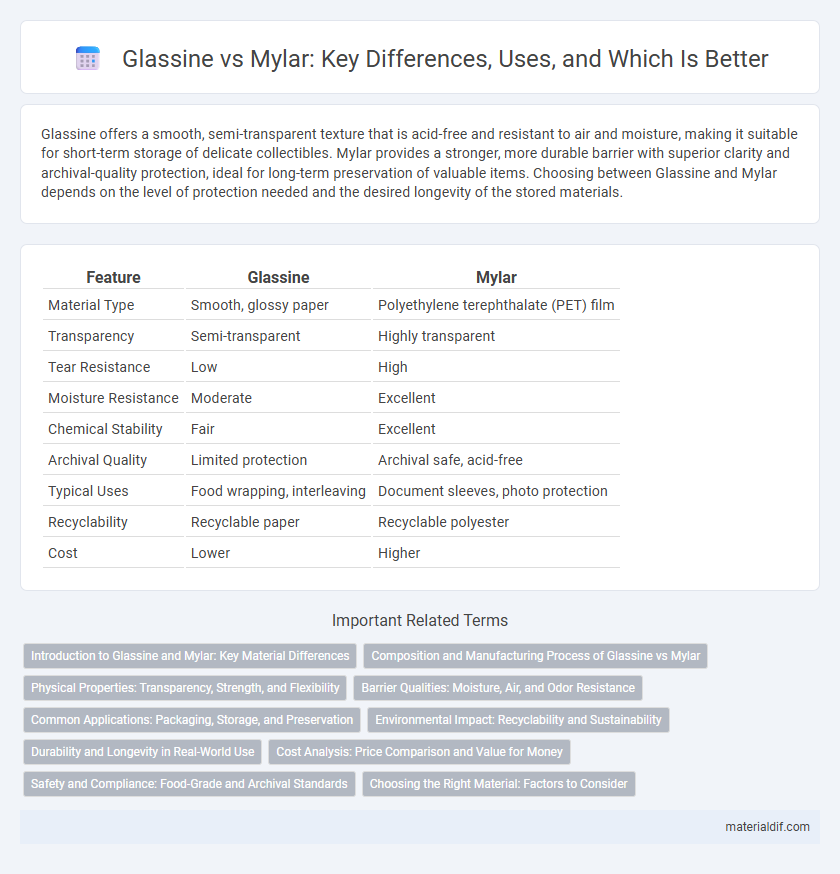

| Feature | Glassine | Mylar |

|---|---|---|

| Material Type | Smooth, glossy paper | Polyethylene terephthalate (PET) film |

| Transparency | Semi-transparent | Highly transparent |

| Tear Resistance | Low | High |

| Moisture Resistance | Moderate | Excellent |

| Chemical Stability | Fair | Excellent |

| Archival Quality | Limited protection | Archival safe, acid-free |

| Typical Uses | Food wrapping, interleaving | Document sleeves, photo protection |

| Recyclability | Recyclable paper | Recyclable polyester |

| Cost | Lower | Higher |

Introduction to Glassine and Mylar: Key Material Differences

Glassine is a smooth, glossy paper known for its resistance to air, water, and grease, often used for archival purposes and protective interleaving. Mylar, a polyester film, offers superior durability, clarity, and resistance to chemicals and moisture, making it ideal for long-term preservation and high-strength applications. Differences in material composition and performance underline Glassine's use as a lightweight barrier, while Mylar provides enhanced protection and longevity in archival storage.

Composition and Manufacturing Process of Glassine vs Mylar

Glassine is a smooth, glossy paper made from refined pulp that undergoes a supercalendering process, resulting in a dense, air- and water-resistant finish. Mylar, on the other hand, is a type of biaxially oriented polyethylene terephthalate (BoPET) film manufactured through extrusion and biaxial stretching, providing superior strength, chemical resistance, and stability. While Glassine's manufacturing emphasizes paper fiber refinement and calendaring, Mylar's production involves polymer synthesis and precise film orientation, leading to distinct physical and chemical properties in the final products.

Physical Properties: Transparency, Strength, and Flexibility

Mylar exhibits higher tensile strength and greater flexibility compared to glassine, making it more durable under stress and less prone to tearing. Both materials offer excellent transparency, but glassine tends to have a matte finish while Mylar provides a clearer, glossy surface. These physical properties position Mylar as a preferred choice for protective sleeves and archival storage where durability and clarity are essential.

Barrier Qualities: Moisture, Air, and Odor Resistance

Mylar outperforms Glassine in barrier qualities, offering superior resistance to moisture, air, and odor infiltration due to its polyester film composition. Glassine, a smooth and glossy paper, provides moderate resistance but is more permeable to vapor and odors compared to Mylar. The enhanced barrier properties of Mylar make it ideal for long-term preservation and protection of sensitive materials.

Common Applications: Packaging, Storage, and Preservation

Mylar, a polyester film known for its strength and clarity, is widely used in packaging due to its moisture and gas barrier properties, making it ideal for food storage and preservation. Glassine, a smooth, glossy paper resistant to air and water, is commonly used for storing archival materials such as stamps and photographs, providing protection without static buildup. While Mylar excels in long-term preservation and industrial packaging, Glassine is preferred for lightweight, breathable storage applications where chemical inertness is crucial.

Environmental Impact: Recyclability and Sustainability

Mylar, a polyester film, is less biodegradable but highly recyclable, offering a sustainable option if properly processed through specialized recycling facilities. Glassine, made from tightly supercalendered paper, is biodegradable and compostable but generally less recyclable due to its coating and processing. Choosing between Glassine and Mylar impacts sustainability goals by balancing biodegradability with the efficiency of recycling infrastructure.

Durability and Longevity in Real-World Use

Mylar offers superior durability and longevity compared to Glassine, resisting tears, moisture, and UV damage more effectively in real-world use. Glassine, while smooth and translucent, tends to yellow and become brittle over time, especially under prolonged exposure to light and humidity. Collectors and archivists prefer Mylar for long-term protection of valuable documents and photographs due to its robust, stable polyester composition.

Cost Analysis: Price Comparison and Value for Money

Glassine typically costs less than Mylar, making it a budget-friendly option for single-use or low-protection needs. Mylar, although priced higher, offers superior durability, chemical resistance, and archival quality, delivering greater long-term value for preserving delicate items. Choosing between Glassine and Mylar depends on balancing upfront cost against the enhanced protection and longevity provided by Mylar sleeves.

Safety and Compliance: Food-Grade and Archival Standards

Glassine and Mylar both offer food-grade safety and archival compliance, but Mylar excels due to its superior chemical inertness and durability. Mylar meets stringent archival standards like ANSI/AIIM Type I, ensuring long-term preservation without risk of off-gassing or degradation. Glassine is food-safe and biodegradable but lacks the high tensile strength and moisture barrier properties essential for prolonged archival use.

Choosing the Right Material: Factors to Consider

When choosing between Glassine and Mylar for archival storage, consider factors such as durability, moisture resistance, and clarity. Mylar offers superior strength and clarity, making it ideal for long-term preservation of valuable documents and photographs, while Glassine provides good protection against grease and moisture but is less durable over time. Assess the specific needs of your materials, including exposure to environmental elements and handling frequency, to select the most appropriate option.

Glassine vs Mylar Infographic

materialdif.com

materialdif.com