Mylar tape offers superior tensile strength and chemical resistance compared to standard polyester tape, making it ideal for industrial applications requiring durability and longevity. Polyester tape, while more flexible and cost-effective, may degrade faster under extreme temperatures and abrasive conditions. Choosing between Mylar tape and polyester tape depends on the specific performance requirements and environmental factors of the intended use.

Table of Comparison

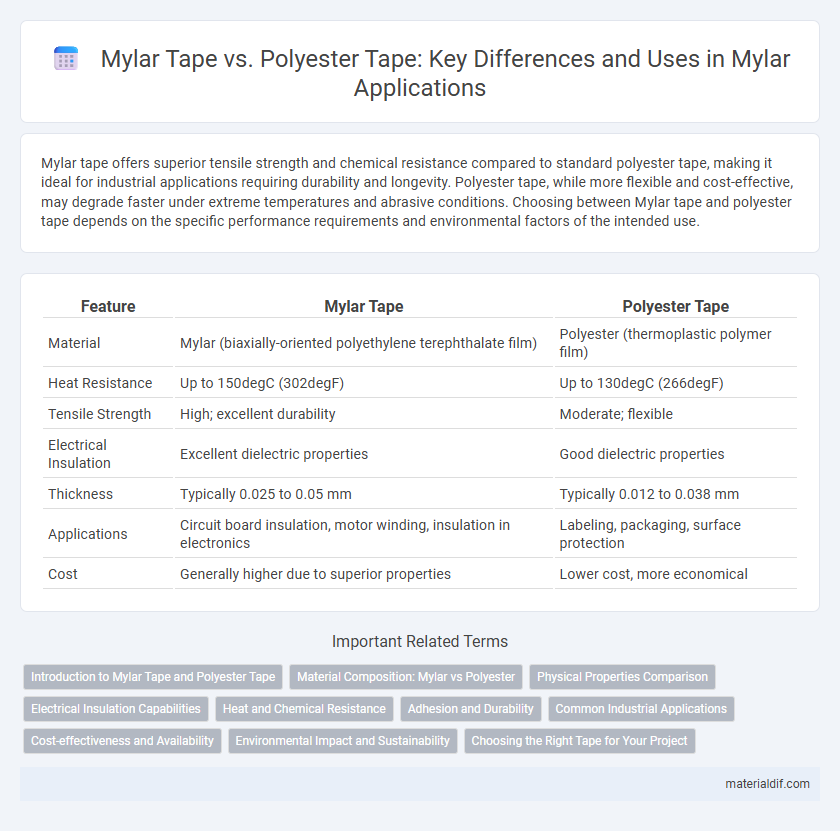

| Feature | Mylar Tape | Polyester Tape |

|---|---|---|

| Material | Mylar (biaxially-oriented polyethylene terephthalate film) | Polyester (thermoplastic polymer film) |

| Heat Resistance | Up to 150degC (302degF) | Up to 130degC (266degF) |

| Tensile Strength | High; excellent durability | Moderate; flexible |

| Electrical Insulation | Excellent dielectric properties | Good dielectric properties |

| Thickness | Typically 0.025 to 0.05 mm | Typically 0.012 to 0.038 mm |

| Applications | Circuit board insulation, motor winding, insulation in electronics | Labeling, packaging, surface protection |

| Cost | Generally higher due to superior properties | Lower cost, more economical |

Introduction to Mylar Tape and Polyester Tape

Mylar Tape, made from biaxially-oriented polyethylene terephthalate (BoPET), offers high tensile strength and excellent electrical insulation properties, making it ideal for applications requiring durability and heat resistance. Polyester Tape, also based on polyethylene terephthalate but with a different finish, provides good chemical resistance and flexibility, suitable for general-purpose masking and insulation tasks. Both tapes deliver strong adhesion and dimensional stability; however, Mylar Tape excels in environments with extreme temperatures and mechanical stress.

Material Composition: Mylar vs Polyester

Mylar tape is made from biaxially-oriented polyethylene terephthalate (BoPET), offering superior tensile strength and dimensional stability compared to standard polyester tape. While both tapes are polyester-based, Mylar undergoes a unique stretching process enhancing its molecular orientation, resulting in higher resistance to heat, chemicals, and moisture. This distinct material composition makes Mylar tape ideal for applications requiring durability and reliability under extreme conditions.

Physical Properties Comparison

Mylar tape exhibits superior tensile strength and dimensional stability compared to standard polyester tape, making it more resistant to stretching and deformation under stress. The dielectric strength of Mylar tape averages around 5000 volts per mil, significantly higher than that of polyester tape, which typically ranges between 3500 and 4000 volts per mil. Temperature resistance for Mylar tape extends up to 150degC, whereas polyester tape generally withstands temperatures up to 120degC, enhancing Mylar's suitability for high-heat applications.

Electrical Insulation Capabilities

Mylar tape offers superior electrical insulation capabilities compared to standard polyester tape due to its higher dielectric strength and resistance to heat and abrasion. Its electrically insulating properties make it ideal for applications in electrical transformers, coils, and motors, where consistent performance under thermal stress is critical. Polyester tape, while cost-effective, typically provides lower dielectric strength and less thermal stability, limiting its effectiveness in advanced electrical insulation applications.

Heat and Chemical Resistance

Mylar tape offers superior heat resistance, maintaining stability at temperatures up to 250degC, compared to standard polyester tape which typically withstands temperatures around 150degC. In terms of chemical resistance, Mylar tape resists solvents, oils, and chemicals better due to its biaxially-oriented polyethylene terephthalate (PET) film composition. These properties make Mylar tape ideal for industrial applications requiring durability in harsh thermal and chemical environments.

Adhesion and Durability

Mylar tape offers superior adhesion compared to standard polyester tape, ensuring a stronger and more reliable bond on various surfaces, including metals and plastics. Its enhanced durability provides excellent resistance to heat, chemicals, and abrasion, making it ideal for demanding industrial applications. Polyester tape, while cost-effective, generally exhibits lower adhesive strength and less resilience under extreme environmental conditions.

Common Industrial Applications

Mylar tape, known for its superior heat resistance and electrical insulation, is extensively used in electrical and electronic industries for motor winding insulation, transformers, and coil wrapping. Polyester tape offers excellent chemical resistance and dimensional stability, making it ideal for circuit board protection, surface masking in powder coating, and splicing applications. Both tapes are integral in manufacturing processes requiring durable, non-conductive, and temperature-resistant materials.

Cost-effectiveness and Availability

Mylar tape offers a cost-effective option due to its durable polyester film backing, which balances price and performance better than traditional polyester tape. Its widespread availability through multiple industrial suppliers enhances accessibility for various applications, reducing lead times and procurement costs. Polyester tape, while similar, often incurs higher costs due to specialty coatings and less market penetration, impacting overall budget efficiency.

Environmental Impact and Sustainability

Mylar tape, made from biaxially-oriented polyethylene terephthalate (PET), often demonstrates better environmental sustainability compared to general polyester tapes due to its higher recyclability and durability, reducing waste over time. The production of Mylar tape typically involves less energy consumption and fewer volatile organic compounds (VOCs) than standard polyester films, contributing to a lower carbon footprint. Choosing Mylar tape supports eco-friendly manufacturing practices and promotes longer product lifecycle, aligning with corporate sustainability goals and environmental regulations.

Choosing the Right Tape for Your Project

Mylar tape offers superior durability, heat resistance up to 150degC, and electrical insulation, making it ideal for electronics and aerospace applications. Polyester tape, while less heat-resistant, provides excellent clarity and flexibility, suitable for labeling and light-duty sealing. Selecting the right tape depends on project requirements like temperature tolerance, mechanical strength, and transparency needs.

Mylar Tape vs Polyester Tape Infographic

materialdif.com

materialdif.com