Mylar offers excellent dimensional stability and clarity, making it ideal for applications requiring transparency and strength, whereas polyimide excels in thermal and chemical resistance, suited for high-temperature environments. While Mylar is cost-effective and widely used in packaging and decorative purposes, polyimide films provide superior insulation and durability in electronics and aerospace industries. Choosing between Mylar and polyimide depends on the specific needs for flexibility, temperature tolerance, and environmental exposure.

Table of Comparison

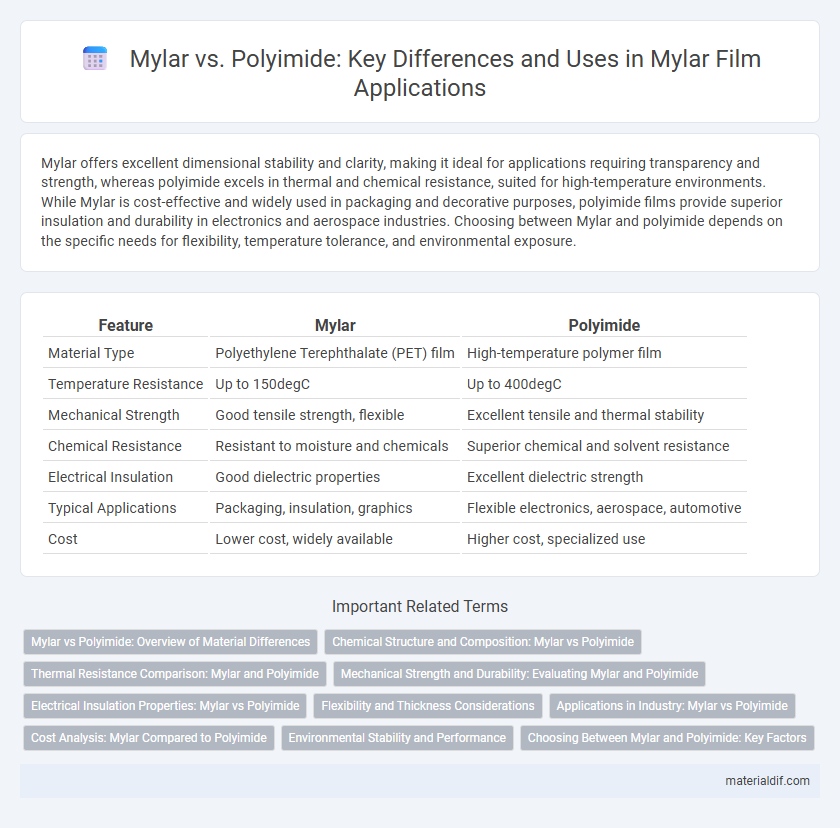

| Feature | Mylar | Polyimide |

|---|---|---|

| Material Type | Polyethylene Terephthalate (PET) film | High-temperature polymer film |

| Temperature Resistance | Up to 150degC | Up to 400degC |

| Mechanical Strength | Good tensile strength, flexible | Excellent tensile and thermal stability |

| Chemical Resistance | Resistant to moisture and chemicals | Superior chemical and solvent resistance |

| Electrical Insulation | Good dielectric properties | Excellent dielectric strength |

| Typical Applications | Packaging, insulation, graphics | Flexible electronics, aerospace, automotive |

| Cost | Lower cost, widely available | Higher cost, specialized use |

Mylar vs Polyimide: Overview of Material Differences

Mylar, a polyester film, offers excellent tensile strength, chemical resistance, and dimensional stability compared to Polyimide, which excels in higher thermal resistance and electrical insulation. Unlike Polyimide, Mylar is more cost-effective and performs well under moderate temperature conditions but has lower heat tolerance, typically up to 150degC versus Polyimide's 260degC. These material differences make Mylar suitable for applications like packaging and insulation where moderate heat resistance suffices, while Polyimide is preferred for high-temperature electronics and aerospace components.

Chemical Structure and Composition: Mylar vs Polyimide

Mylar, a biaxially-oriented polyethylene terephthalate (BoPET), consists of ester linkages formed from terephthalic acid and ethylene glycol, resulting in a highly crystalline polyester structure known for its strength and clarity. Polyimide features aromatic imide rings derived from the polymerization of dianhydrides and diamines, providing exceptional thermal stability and chemical resistance due to its rigid heterocyclic backbone. The fundamental difference in chemical composition, polyester ester bonds versus polyimide imide rings, governs Mylar's mechanical flexibility and optical properties versus polyimide's durability in extreme environments.

Thermal Resistance Comparison: Mylar and Polyimide

Mylar, a type of polyester film, offers thermal resistance up to approximately 150degC, making it suitable for moderate heat applications. Polyimide films, such as Kapton, exhibit superior thermal resistance, withstanding temperatures up to 400degC or higher, ideal for high-temperature environments. This significant difference positions Polyimide as the preferred choice for electronics and aerospace industries requiring extreme thermal stability.

Mechanical Strength and Durability: Evaluating Mylar and Polyimide

Mylar exhibits high tensile strength and excellent durability, making it resistant to stretching and tearing under mechanical stress. Polyimide outperforms Mylar in thermal stability and maintains superior mechanical strength at elevated temperatures, offering enhanced durability in harsh environments. When selecting materials for applications requiring robust mechanical performance and long-term durability, Polyimide is preferred over Mylar for extreme conditions, while Mylar is suitable for moderately demanding mechanical uses.

Electrical Insulation Properties: Mylar vs Polyimide

Mylar offers excellent electrical insulation with a high dielectric strength of around 5000 V/mil, making it suitable for general-purpose insulation applications. Polyimide surpasses Mylar in thermal stability and maintains superior electrical insulation properties at elevated temperatures up to 400degC, with dielectric strength typically around 7000 V/mil. These distinctions make Polyimide the preferred choice for high-temperature and high-performance electrical insulation needs, while Mylar excels in cost-effective, lower-temperature applications.

Flexibility and Thickness Considerations

Mylar typically offers greater flexibility compared to polyimide, making it suitable for applications requiring extensive bending or folding. In terms of thickness, Mylar films are available in a wide range, usually from 12 to 250 microns, allowing customization for lightweight or robust needs, whereas polyimide films tend to have a higher minimum thickness but provide superior thermal stability. The choice between Mylar and polyimide depends largely on balancing flexibility requirements with thickness constraints for specific industrial or electronic uses.

Applications in Industry: Mylar vs Polyimide

Mylar excels in applications requiring high tensile strength, chemical stability, and electrical insulation, making it ideal for flexible packaging, electrical insulation, and solar panel substrates. Polyimide offers superior thermal stability and chemical resistance, preferred in aerospace, microelectronics, and high-temperature electrical insulation. Both materials serve critical industrial roles, with Mylar favored for cost-effectiveness and flexibility, while Polyimide is chosen for durability in extreme environments.

Cost Analysis: Mylar Compared to Polyimide

Mylar offers a significant cost advantage over polyimide, with prices generally ranging from 30% to 50% lower depending on thickness and supplier volume discounts. While polyimide films provide superior thermal stability and chemical resistance, the lower material and processing costs of Mylar make it an economical choice for applications with moderate temperature and environmental demands. Manufacturers prioritize Mylar for high-volume, cost-sensitive products, whereas polyimide is reserved for specialized uses where performance justifies the premium.

Environmental Stability and Performance

Mylar, a polyester film, offers superior environmental stability compared to polyimide, resisting moisture, UV radiation, and temperature fluctuations effectively. Polyimide films excel in high-temperature applications but can degrade under prolonged UV exposure and moisture conditions. Mylar's balanced performance in durability and environmental resistance makes it preferable for outdoor and general-use applications requiring long-term stability.

Choosing Between Mylar and Polyimide: Key Factors

Mylar offers excellent tensile strength, clarity, and moisture resistance, making it ideal for applications requiring durability and flexibility. Polyimide excels in high-temperature environments, maintaining stability up to 400degC, which suits electronic insulation and aerospace uses. When choosing between Mylar and Polyimide, consider thermal tolerance, chemical resistance, and mechanical properties relevant to the specific industrial requirements.

Mylar vs Polyimide Infographic

materialdif.com

materialdif.com