Mylar labels offer superior durability and resistance to moisture, chemicals, and abrasion compared to paper labels, making them ideal for long-lasting identification. Unlike paper labels, Mylar labels maintain clarity and adhesion in harsh environments, ensuring consistent readability and performance. This makes Mylar the preferred choice for industrial, outdoor, and high-wear applications where label longevity is critical.

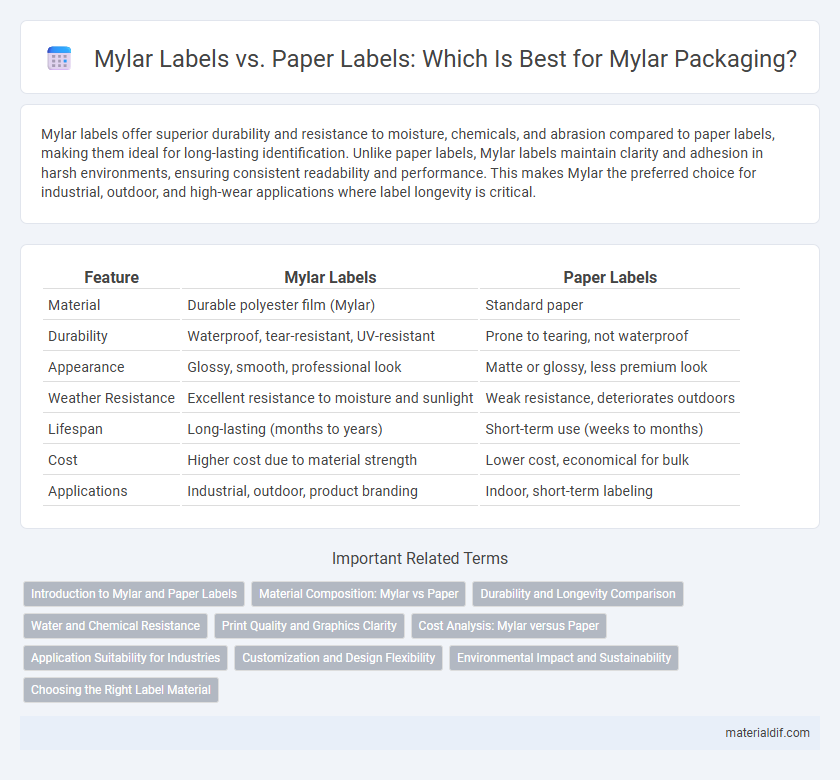

Table of Comparison

| Feature | Mylar Labels | Paper Labels |

|---|---|---|

| Material | Durable polyester film (Mylar) | Standard paper |

| Durability | Waterproof, tear-resistant, UV-resistant | Prone to tearing, not waterproof |

| Appearance | Glossy, smooth, professional look | Matte or glossy, less premium look |

| Weather Resistance | Excellent resistance to moisture and sunlight | Weak resistance, deteriorates outdoors |

| Lifespan | Long-lasting (months to years) | Short-term use (weeks to months) |

| Cost | Higher cost due to material strength | Lower cost, economical for bulk |

| Applications | Industrial, outdoor, product branding | Indoor, short-term labeling |

Introduction to Mylar and Paper Labels

Mylar labels, made from polyester film, offer superior durability, water resistance, and tear-proof qualities compared to traditional paper labels. Paper labels, while more cost-effective and easier to print on, lack the resilience and longevity of Mylar, making them less suitable for harsh or outdoor environments. The choice between Mylar and paper labels depends on the specific application requirements, including exposure to moisture, temperature, and wear.

Material Composition: Mylar vs Paper

Mylar labels consist of biaxially oriented polyethylene terephthalate (BoPET), a durable polyester film offering superior resistance to moisture, chemicals, and temperature variations, unlike paper labels, which are primarily cellulose-based and prone to tearing and warping under similar conditions. The synthetic structure of Mylar provides enhanced dimensional stability and longevity, making it ideal for industrial, outdoor, or high-wear applications where paper labels would deteriorate quickly. Paper labels, although cost-effective and biodegradable, lack the protective barrier qualities and tensile strength inherent in Mylar, limiting their use in environments requiring robust label durability.

Durability and Longevity Comparison

Mylar labels offer superior durability and longevity compared to paper labels due to their polyester film composition, which provides resistance to water, chemicals, and UV exposure. Unlike paper labels that easily tear, fade, or degrade under harsh conditions, Mylar labels maintain clarity and adhesion for extended periods. This makes Mylar labels ideal for industrial, outdoor, and high-moisture environments where long-lasting performance is critical.

Water and Chemical Resistance

Mylar labels offer superior water and chemical resistance compared to paper labels, making them ideal for harsh environments where exposure to moisture and solvents is common. The polyester film in Mylar provides a durable, non-absorbent surface that prevents ink smudging and deterioration under wet or corrosive conditions. Paper labels, by contrast, tend to absorb liquids and degrade quickly, limiting their use in industrial, laboratory, and outdoor applications requiring longevity and resilience.

Print Quality and Graphics Clarity

Mylar labels consistently outperform paper labels in print quality due to their smooth, non-porous surface, allowing for sharper, more vibrant graphics and precise detail reproduction. The durability of Mylar material prevents ink bleeding and smudging, ensuring long-lasting clarity even under exposure to moisture and abrasion. High-resolution printing on Mylar enhances brand visibility by maintaining crisp colors and intricate designs that paper labels often fail to sustain over time.

Cost Analysis: Mylar versus Paper

Mylar labels generally incur higher initial costs than paper labels due to their durable polyester film material, which provides enhanced resistance to moisture, chemicals, and tearing, making them ideal for long-term applications. Despite the upfront expense, Mylar labels offer greater longevity and reduced replacement frequency, potentially lowering total lifecycle costs compared to paper labels that may require frequent reprinting or replacement in harsh environments. For businesses prioritizing durability and long-term savings, the investment in Mylar labels often results in better cost efficiency than the cheaper but less resilient paper options.

Application Suitability for Industries

Mylar labels provide superior durability, resistance to moisture, chemicals, and extreme temperatures, making them ideal for harsh industrial environments such as automotive, manufacturing, and electronics. Paper labels, while cost-effective and suitable for short-term applications, lack the resilience required for outdoor use or exposure to abrasion and solvents. Industries demanding long-lasting, high-performance labeling choose Mylar for enhanced longevity and professional appearance.

Customization and Design Flexibility

Mylar labels offer superior customization and design flexibility compared to traditional paper labels, accommodating intricate shapes, metallic finishes, and vibrant colors that enhance brand visibility. Their durable, water-resistant surface allows for printing detailed graphics and fine text without smudging or fading, making them ideal for high-quality, long-lasting labels. Unlike paper labels, Mylar supports advanced printing techniques such as embossing and foil stamping, providing a premium appearance that elevates product packaging.

Environmental Impact and Sustainability

Mylar labels offer superior durability and water resistance, reducing waste from damaged or discarded labels compared to paper labels. Although Mylar is a polyester film derived from petrochemicals, its recyclability and long lifespan contribute to lower environmental impact in the long term. In contrast, paper labels are biodegradable but often require more frequent replacement, leading to higher resource consumption and waste generation.

Choosing the Right Label Material

Mylar labels offer superior durability, resistance to moisture, chemicals, and temperature extremes compared to paper labels, making them ideal for harsh environments and long-term applications. Paper labels provide cost-effective, easy customization and biodegradability, suitable for short-term use and indoor settings where resistance factors are less critical. Selecting the right label material depends on application requirements such as exposure conditions, longevity, and budget constraints to ensure optimal performance and sustainability.

Mylar Labels vs Paper Labels Infographic

materialdif.com

materialdif.com