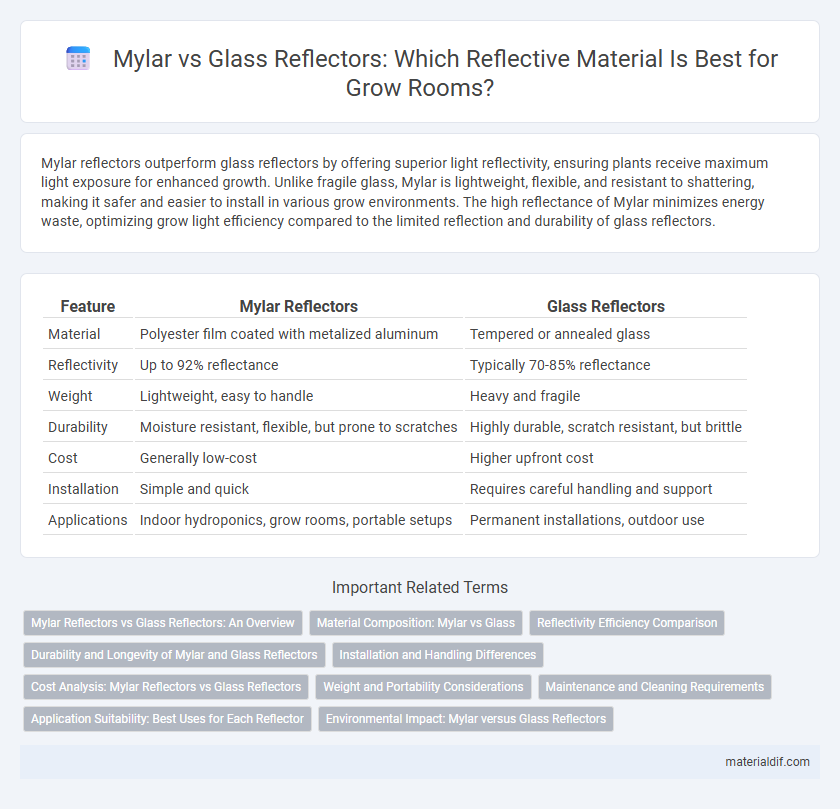

Mylar reflectors outperform glass reflectors by offering superior light reflectivity, ensuring plants receive maximum light exposure for enhanced growth. Unlike fragile glass, Mylar is lightweight, flexible, and resistant to shattering, making it safer and easier to install in various grow environments. The high reflectance of Mylar minimizes energy waste, optimizing grow light efficiency compared to the limited reflection and durability of glass reflectors.

Table of Comparison

| Feature | Mylar Reflectors | Glass Reflectors |

|---|---|---|

| Material | Polyester film coated with metalized aluminum | Tempered or annealed glass |

| Reflectivity | Up to 92% reflectance | Typically 70-85% reflectance |

| Weight | Lightweight, easy to handle | Heavy and fragile |

| Durability | Moisture resistant, flexible, but prone to scratches | Highly durable, scratch resistant, but brittle |

| Cost | Generally low-cost | Higher upfront cost |

| Installation | Simple and quick | Requires careful handling and support |

| Applications | Indoor hydroponics, grow rooms, portable setups | Permanent installations, outdoor use |

Mylar Reflectors vs Glass Reflectors: An Overview

Mylar reflectors offer superior light reflectivity, boasting up to 95% reflectance compared to 70-85% for glass reflectors, making them ideal for maximizing illumination efficiency. They are lightweight, flexible, and more resistant to shattering than glass, enhancing safety and ease of installation in various applications such as horticulture and photography. Unlike glass reflectors, Mylar is moisture-resistant and does not degrade easily, providing longer-lasting performance in humid or variable environments.

Material Composition: Mylar vs Glass

Mylar reflectors are made from a polyester film coated with a thin layer of metal, typically aluminum, which provides high reflectivity and lightweight durability. Glass reflectors consist of thick, rigid glass with a reflective metal backing, offering superior rigidity but increased weight and fragility. The flexible nature of Mylar allows for easy installation and adaptability in various reflector shapes, while glass's solid composition supports long-term structural stability but limits versatility.

Reflectivity Efficiency Comparison

Mylar reflectors exhibit reflectivity efficiencies ranging from 85% to 95%, outperforming standard glass reflectors that typically achieve around 70% to 80%. The high reflectivity of Mylar results from its smooth, metalized polyester surface, which reduces light absorption and scatter. Compared to glass, which can suffer from internal reflection losses and weight limitations, Mylar offers superior efficiency and flexibility in various lighting and solar energy applications.

Durability and Longevity of Mylar and Glass Reflectors

Mylar reflectors offer superior durability compared to glass reflectors due to their resistance to shattering and lightweight, flexible properties. Glass reflectors, while providing high reflectivity, are prone to breakage and weathering over time, reducing their longevity in outdoor applications. The polymer composition of Mylar enables it to maintain reflectivity and structural integrity longer under varying environmental conditions.

Installation and Handling Differences

Mylar reflectors offer a lightweight and flexible alternative to glass reflectors, simplifying installation processes due to their easy cutting and shaping capabilities. Unlike fragile glass reflectors that require careful handling and mounting hardware, Mylar can be quickly attached to various surfaces with adhesive or framing methods, reducing labor time and cost. Their durability and resistance to shattering make Mylar reflectors safer and more convenient for applications where frequent adjustments or repositioning are necessary.

Cost Analysis: Mylar Reflectors vs Glass Reflectors

Mylar reflectors offer a cost-effective alternative to glass reflectors, with prices typically 40-60% lower due to cheaper raw materials and simpler manufacturing processes. While glass reflectors provide higher durability and reflectivity, the initial investment and replacement costs make Mylar an attractive choice for budget-sensitive projects. Maintenance expenses for Mylar are generally lower, but its lifespan averages 3-5 years compared to glass reflectors that can last up to 20 years, impacting long-term cost analysis.

Weight and Portability Considerations

Mylar reflectors are significantly lighter and more flexible compared to traditional glass reflectors, enhancing portability for on-the-go applications. Their lightweight nature allows for easy transport and quick setup, making them ideal for mobile photography or outdoor lighting. Glass reflectors, while more durable, tend to be heavier and bulkier, which can limit ease of movement and increase handling effort.

Maintenance and Cleaning Requirements

Mylar reflectors require minimal maintenance due to their lightweight, flexible polyester film construction, which resists corrosion and dirt buildup better than glass. Glass reflectors demand frequent cleaning to prevent dust and grime accumulation that can reduce reflectivity and often require careful handling to avoid cracking or chipping. The durability and ease of cleaning Mylar reflectors make them more cost-effective and convenient for long-term use in solar and lighting applications.

Application Suitability: Best Uses for Each Reflector

Mylar reflectors excel in indoor horticulture and hydroponics due to their high reflectivity and lightweight flexibility, making them ideal for maximizing light efficiency in grow tents and controlled environments. Glass reflectors, with superior durability and heat resistance, are better suited for industrial and outdoor applications where longevity and high-temperature tolerance are crucial. Each reflector type offers distinct advantages depending on environmental conditions and specific light management requirements.

Environmental Impact: Mylar versus Glass Reflectors

Mylar reflectors have a significantly lower environmental impact compared to glass reflectors due to their lightweight nature and reduced energy consumption during production. Unlike glass, which requires high-temperature melting processes and results in higher carbon emissions, Mylar manufacturing emits fewer greenhouse gases and allows easier recycling options. The durability and flexibility of Mylar also reduce material waste and transportation fuel usage, contributing to a more sustainable reflector choice.

Mylar Reflectors vs Glass Reflectors Infographic

materialdif.com

materialdif.com