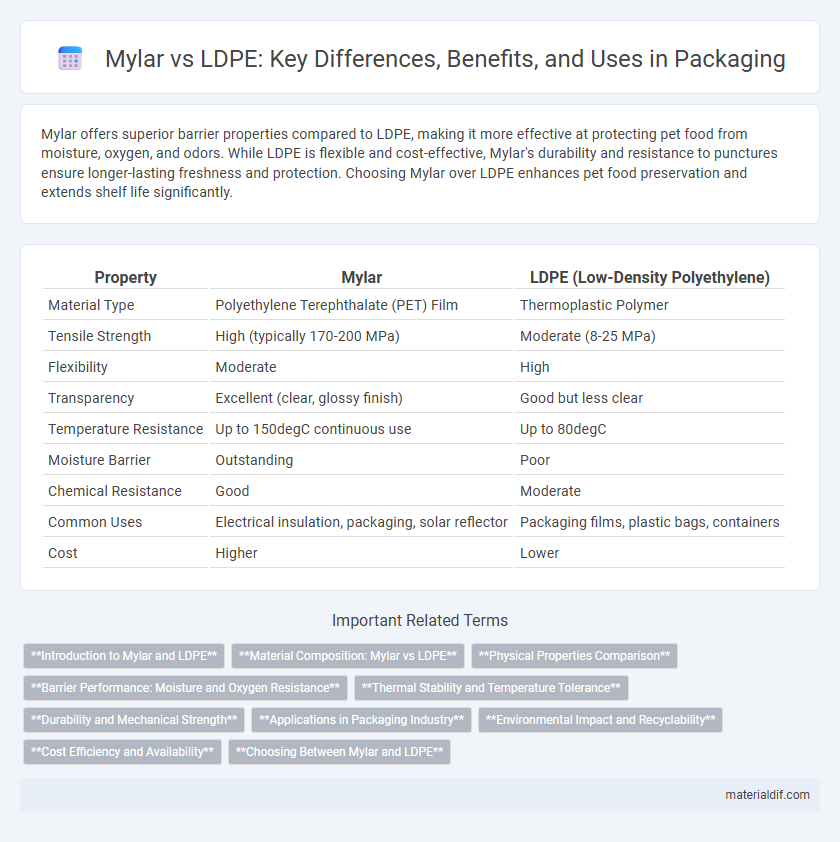

Mylar offers superior barrier properties compared to LDPE, making it more effective at protecting pet food from moisture, oxygen, and odors. While LDPE is flexible and cost-effective, Mylar's durability and resistance to punctures ensure longer-lasting freshness and protection. Choosing Mylar over LDPE enhances pet food preservation and extends shelf life significantly.

Table of Comparison

| Property | Mylar | LDPE (Low-Density Polyethylene) |

|---|---|---|

| Material Type | Polyethylene Terephthalate (PET) Film | Thermoplastic Polymer |

| Tensile Strength | High (typically 170-200 MPa) | Moderate (8-25 MPa) |

| Flexibility | Moderate | High |

| Transparency | Excellent (clear, glossy finish) | Good but less clear |

| Temperature Resistance | Up to 150degC continuous use | Up to 80degC |

| Moisture Barrier | Outstanding | Poor |

| Chemical Resistance | Good | Moderate |

| Common Uses | Electrical insulation, packaging, solar reflector | Packaging films, plastic bags, containers |

| Cost | Higher | Lower |

Introduction to Mylar and LDPE

Mylar, a polyester film known for its high tensile strength, chemical stability, and excellent barrier properties, is commonly used in packaging, insulation, and electronics. LDPE (Low-Density Polyethylene) is a flexible, lightweight plastic widely utilized for bags, containers, and film applications due to its moisture resistance and low cost. The fundamental difference between Mylar and LDPE lies in Mylar's superior durability and thermal resistance compared to LDPE's flexibility and ease of processing.

Material Composition: Mylar vs LDPE

Mylar is a polyester film made from polyethylene terephthalate (PET), known for its high tensile strength, chemical stability, and excellent barrier properties against moisture and gases. LDPE (Low-Density Polyethylene) is a thermoplastic made from the polymerization of ethylene, characterized by its flexibility, low moisture vapor transmission rate, and lower tensile strength compared to Mylar. The distinct molecular structures give Mylar superior durability and clarity, while LDPE offers greater flexibility and cost-effectiveness for packaging applications.

Physical Properties Comparison

Mylar exhibits superior tensile strength and higher temperature resistance compared to LDPE, making it ideal for applications requiring durability and heat stability. Unlike LDPE, Mylar has a lower moisture vapor transmission rate, enhancing its effectiveness as a barrier material. Its dimensional stability and resistance to stretching surpass those of LDPE, providing consistent performance in packaging and insulation uses.

Barrier Performance: Moisture and Oxygen Resistance

Mylar exhibits superior barrier performance against moisture and oxygen compared to LDPE, making it ideal for packaging applications requiring extended shelf life. The polyester composition of Mylar provides low permeability to gases and water vapor, significantly reducing oxidation and moisture ingress. LDPE, while flexible and cost-effective, offers higher permeability rates that limit its suitability for sensitive products needing enhanced protection.

Thermal Stability and Temperature Tolerance

Mylar exhibits superior thermal stability and temperature tolerance compared to LDPE, maintaining structural integrity at temperatures up to 150degC, whereas LDPE typically softens around 80-90degC. This enhanced heat resistance makes Mylar ideal for applications requiring prolonged exposure to elevated temperatures, such as electrical insulation and high-performance packaging. LDPE's lower melting point limits its use in high-heat environments, favoring Mylar for thermal-sensitive functions.

Durability and Mechanical Strength

Mylar exhibits superior durability and mechanical strength compared to LDPE due to its polyester composition, which provides greater tensile strength and resistance to stretching or tearing. LDPE, being a more flexible and softer plastic, tends to have lower impact resistance and is more prone to punctures under stress. This makes Mylar ideal for applications requiring long-lasting, robust protection, such as packaging, insulation, and industrial films.

Applications in Packaging Industry

Mylar offers superior barrier properties against oxygen, moisture, and gases, making it ideal for food packaging that requires extended shelf life and freshness preservation. LDPE is favored for flexible packaging applications due to its excellent sealability, toughness, and low cost, often used for bags, liners, and shrink films. In the packaging industry, Mylar is preferred for high-performance packaging requiring durability and product protection, while LDPE suits cost-effective, flexible packaging solutions for everyday consumer goods.

Environmental Impact and Recyclability

Mylar, a polyester film, offers superior recyclability compared to LDPE due to its chemical stability and ability to be recycled into high-quality products, reducing landfill waste. LDPE, while widely used for packaging, often faces challenges in recycling infrastructure and tends to degrade in quality after recycling, contributing to environmental pollution. The durability and longer lifespan of Mylar also result in less frequent replacements, lowering overall environmental impact.

Cost Efficiency and Availability

Mylar offers moderate cost efficiency with high durability but is generally more expensive than LDPE, which is widely recognized for its low price and extensive availability. LDPE's mass production ensures consistent supply and affordability, making it a preferred choice for budget-conscious packaging and protective applications. Despite higher costs, Mylar's superior strength and barrier properties justify its use where performance outweighs initial expense.

Choosing Between Mylar and LDPE

Mylar offers superior barrier properties, including high resistance to moisture, oxygen, and chemicals, making it ideal for long-term food storage and electronic packaging compared to LDPE. LDPE is more flexible and cost-effective, with excellent tear resistance and suitability for applications requiring easy sealing and lower environmental impact. Selecting between Mylar and LDPE depends on the priority of durability, barrier protection, and application-specific demands such as temperature tolerance and transparency.

Mylar vs LDPE Infographic

materialdif.com

materialdif.com