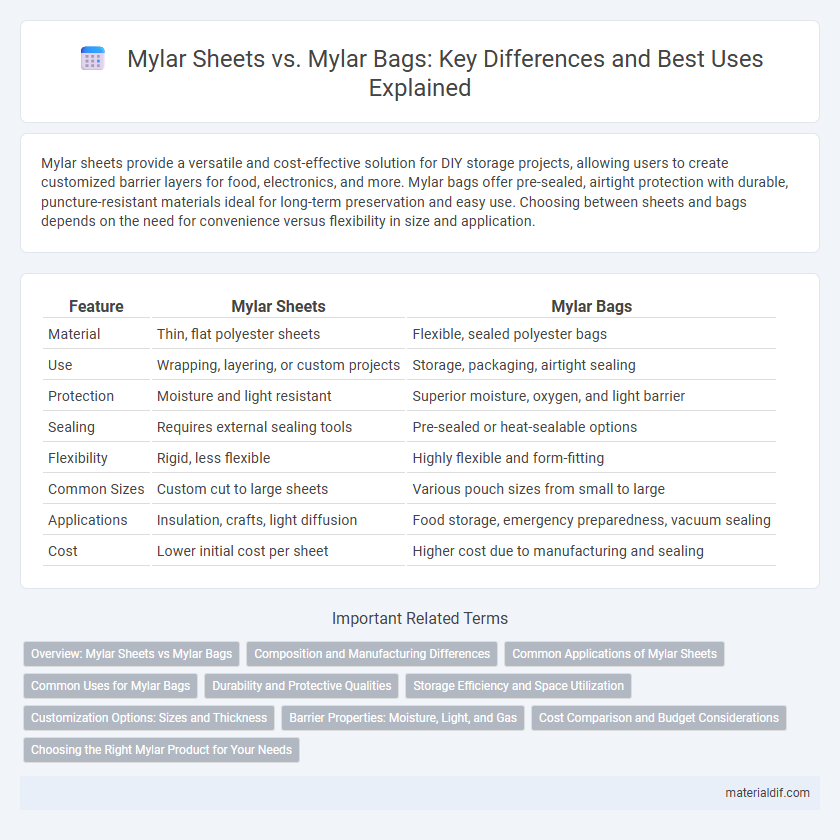

Mylar sheets provide a versatile and cost-effective solution for DIY storage projects, allowing users to create customized barrier layers for food, electronics, and more. Mylar bags offer pre-sealed, airtight protection with durable, puncture-resistant materials ideal for long-term preservation and easy use. Choosing between sheets and bags depends on the need for convenience versus flexibility in size and application.

Table of Comparison

| Feature | Mylar Sheets | Mylar Bags |

|---|---|---|

| Material | Thin, flat polyester sheets | Flexible, sealed polyester bags |

| Use | Wrapping, layering, or custom projects | Storage, packaging, airtight sealing |

| Protection | Moisture and light resistant | Superior moisture, oxygen, and light barrier |

| Sealing | Requires external sealing tools | Pre-sealed or heat-sealable options |

| Flexibility | Rigid, less flexible | Highly flexible and form-fitting |

| Common Sizes | Custom cut to large sheets | Various pouch sizes from small to large |

| Applications | Insulation, crafts, light diffusion | Food storage, emergency preparedness, vacuum sealing |

| Cost | Lower initial cost per sheet | Higher cost due to manufacturing and sealing |

Overview: Mylar Sheets vs Mylar Bags

Mylar sheets and Mylar bags both provide excellent moisture and oxygen barriers, enhancing long-term storage for food, electronics, and sensitive materials. While Mylar sheets offer flexible, flat protection often used for wrapping or laminating, Mylar bags come pre-formed with sealed edges, ideal for vacuum sealing and airtight packaging. The choice depends on storage needs, with sheets preferred for customizable coverage and bags favored for secure, ready-to-use containment.

Composition and Manufacturing Differences

Mylar sheets are made from biaxially-oriented polyethylene terephthalate (BoPET) produced through a film extrusion process, resulting in thin, flexible sheets primarily used for insulation, packaging, and decorative applications. In contrast, Mylar bags are fabricated by heat-sealing multiple layers of Mylar film combined with barrier materials such as aluminum foil and polyethylene to create airtight, moisture-resistant packaging solutions. The manufacturing of Mylar bags involves laminating and sealing techniques that provide enhanced protection compared to the single-layer, unsealed nature of Mylar sheets.

Common Applications of Mylar Sheets

Mylar sheets are widely used in insulation, packaging, and protective covers due to their durability, moisture resistance, and reflective properties. Common applications include thermal insulation in windows, emergency blankets, and decorative crafts, where flexibility and clarity are essential. Unlike Mylar bags, sheets are preferred for flat surface protection and layering, making them ideal for various industrial and consumer uses.

Common Uses for Mylar Bags

Mylar bags are widely used for long-term food storage, preserving freshness and protecting contents from moisture, oxygen, and light exposure. These bags are ideal for packaging dehydrated goods, coffee, and emergency supplies due to their airtight seals and durability. Compared to Mylar sheets, which are often used for insulation or craft purposes, Mylar bags provide enhanced convenience and protection for edible and sensitive products.

Durability and Protective Qualities

Mylar sheets offer exceptional durability with high resistance to moisture, oxygen, and UV light, making them ideal for long-term protection against environmental factors. Mylar bags provide superior airtight sealing capabilities, enhancing the preservation of food and sensitive items by preventing contamination and extending shelf life. Both materials utilize polyethylene terephthalate (PET) but differ in application flexibility, with sheets favoring broader surface coverage and bags enabling compact, secure storage.

Storage Efficiency and Space Utilization

Mylar bags offer superior storage efficiency compared to Mylar sheets by sealing contents in airtight, space-saving compartments that reduce exposure to moisture and air. Mylar sheets require additional materials like vacuum sealers or containers to achieve similar protection, often resulting in bulkier storage solutions. The compact nature of Mylar bags enhances space utilization, making them ideal for storing food, electronics, or documents in limited storage areas.

Customization Options: Sizes and Thickness

Mylar sheets offer versatile customization options with a wide range of sizes and thicknesses, allowing precise tailoring for various craft and packaging needs. Mylar bags typically come in pre-set dimensions but can be ordered in custom sizes for specific storage or preservation purposes, often featuring standardized thickness for durability and barrier protection. Both formats provide flexibility, but sheets excel where size variability and thickness adjustment are critical for project-specific requirements.

Barrier Properties: Moisture, Light, and Gas

Mylar sheets provide excellent moisture and gas barrier properties, making them ideal for applications requiring airtight and moisture-resistant packaging. Mylar bags enhance these barrier properties with sealed edges, offering superior protection against light, moisture, and oxygen infiltration. Both forms utilize biaxially oriented polyethylene terephthalate (BoPET) film, but bags are preferred for long-term storage due to their convenient closure and enhanced sealing capabilities.

Cost Comparison and Budget Considerations

Mylar sheets typically cost less than Mylar bags, making them a budget-friendly option for bulk storage or insulation projects. Although Mylar bags are more expensive due to their resealable and protective features, they offer added value for preserving food freshness and preventing contamination. Evaluating long-term savings and specific storage needs helps determine the most cost-effective choice between Mylar sheets and bags.

Choosing the Right Mylar Product for Your Needs

Mylar sheets offer versatility for crafting, insulation, and DIY projects due to their flat, flexible design, while Mylar bags provide superior protection for food storage with airtight and moisture-proof seals. Selecting between Mylar sheets and Mylar bags depends on whether you need customizable shaping or secure packaging for long-term preservation. For food storage, Mylar bags with oxygen absorbers ensure extended freshness, whereas sheets are ideal for thermal insulation and reflective purposes.

Mylar Sheets vs Mylar Bags Infographic

materialdif.com

materialdif.com