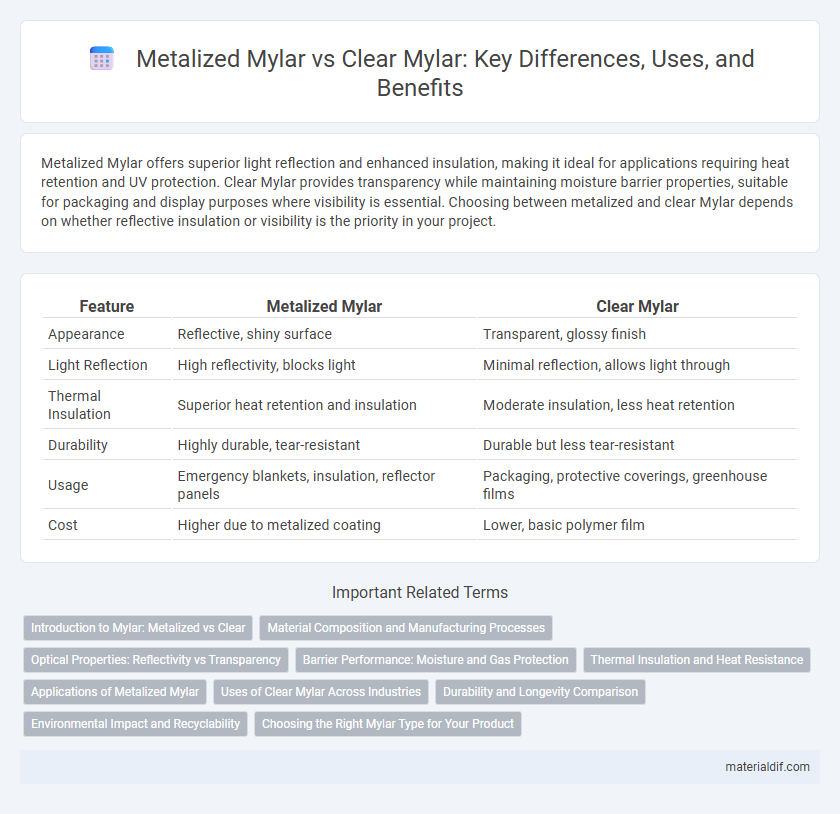

Metalized Mylar offers superior light reflection and enhanced insulation, making it ideal for applications requiring heat retention and UV protection. Clear Mylar provides transparency while maintaining moisture barrier properties, suitable for packaging and display purposes where visibility is essential. Choosing between metalized and clear Mylar depends on whether reflective insulation or visibility is the priority in your project.

Table of Comparison

| Feature | Metalized Mylar | Clear Mylar |

|---|---|---|

| Appearance | Reflective, shiny surface | Transparent, glossy finish |

| Light Reflection | High reflectivity, blocks light | Minimal reflection, allows light through |

| Thermal Insulation | Superior heat retention and insulation | Moderate insulation, less heat retention |

| Durability | Highly durable, tear-resistant | Durable but less tear-resistant |

| Usage | Emergency blankets, insulation, reflector panels | Packaging, protective coverings, greenhouse films |

| Cost | Higher due to metalized coating | Lower, basic polymer film |

Introduction to Mylar: Metalized vs Clear

Metalized Mylar features a thin layer of metal, typically aluminum, which enhances its reflective properties and provides superior barrier protection against moisture, light, and gases. Clear Mylar, made from biaxially oriented polyethylene terephthalate (BoPET), offers excellent strength, flexibility, and transparency, making it ideal for applications requiring visibility and moderate protection. The choice between Metalized and Clear Mylar depends on the balance between durability, protection level, and visual requirements for packaging, insulation, or decorative uses.

Material Composition and Manufacturing Processes

Metalized Mylar consists of a polyester film coated with a thin layer of aluminum achieved through vacuum deposition, enhancing its reflective properties and barrier strength. Clear Mylar is uncoated biaxially-oriented polyethylene terephthalate (BoPET) film that maintains transparency and high tensile strength without metallic interference. Manufacturing Metalized Mylar involves a metallization step post-extrusion, while Clear Mylar undergoes direct film extrusion and orientation without further coating processes.

Optical Properties: Reflectivity vs Transparency

Metalized Mylar exhibits high reflectivity due to its thin metal coating, making it ideal for applications requiring light reflection and insulation. Clear Mylar, on the other hand, offers excellent transparency and minimal light distortion, suitable for protective coverings and optical clarity. The choice between Metalized and Clear Mylar hinges on the need for reflective properties versus the requirement for visibility and light transmission.

Barrier Performance: Moisture and Gas Protection

Metalized Mylar films offer superior barrier performance against moisture and gases due to their aluminum coating, which significantly reduces permeability compared to clear Mylar. Clear Mylar, while providing excellent transparency and durability, has higher moisture and oxygen transmission rates, making it less effective for applications requiring airtight protection. The enhanced barrier properties of metalized Mylar make it ideal for food packaging, electronics, and sensitive product preservation.

Thermal Insulation and Heat Resistance

Metalized Mylar offers superior thermal insulation and heat resistance compared to Clear Mylar due to its reflective aluminum coating that effectively reflects radiant heat and reduces heat transfer. Clear Mylar lacks this reflective layer, making it less effective at retaining or deflecting heat under high-temperature conditions. Consequently, Metalized Mylar is preferred in applications requiring enhanced heat retention and thermal barrier properties.

Applications of Metalized Mylar

Metalized Mylar enhances insulation and reflective properties, making it ideal for applications in thermal blankets, emergency shelters, and insulation in electronics. Its metal coating improves durability and light reflectivity, which is crucial in packaging sensitive products and solar control films. Industries rely on Metalized Mylar for moisture barriers, electrical insulation, and decorative purposes where enhanced performance and aesthetics are required.

Uses of Clear Mylar Across Industries

Clear Mylar offers exceptional clarity and durability, making it ideal for packaging in the food and pharmaceutical industries where product visibility is essential. In electronics, Clear Mylar serves as an insulating film due to its excellent dielectric properties and heat resistance. The graphic arts and printing sectors utilize Clear Mylar for overlays and protective covers, benefiting from its transparency and dimensional stability.

Durability and Longevity Comparison

Metalized Mylar exhibits superior durability due to its aluminum coating, which enhances resistance to moisture, UV rays, and tearing compared to Clear Mylar's basic polyester film. The reflective surface of Metalized Mylar contributes to extended longevity in outdoor and high-stress environments, whereas Clear Mylar is more prone to degradation and yellowing over time. For applications demanding long-term preservation and robust protection, Metalized Mylar offers a more reliable and resilient solution.

Environmental Impact and Recyclability

Metalized Mylar contains an aluminum coating that significantly reduces its recyclability compared to Clear Mylar, which is made from pure polyester film and is easier to recycle. The environmental impact of Metalized Mylar is higher due to the energy-intensive metalizing process and difficulty in separation during recycling, leading to more landfill waste. Clear Mylar's simpler composition allows for more efficient recycling and less environmental burden, making it a more sustainable choice for packaging and insulation applications.

Choosing the Right Mylar Type for Your Product

Metalized Mylar offers superior light reflection and moisture barrier properties, making it ideal for packaging products sensitive to light and humidity. Clear Mylar provides transparency for product visibility while maintaining good resistance to oxygen and moisture, suitable for showcasing items. Selecting the right Mylar depends on whether protection from environmental factors or visibility of the product is the priority.

Metalized Mylar vs Clear Mylar Infographic

materialdif.com

materialdif.com