Heat seal Mylar offers a strong, airtight closure achieved by applying heat to activate an adhesive, ensuring optimal freshness and durability for pet packaging. Cold seal Mylar relies on pressure-sensitive adhesives that bond at room temperature without heat, providing quick and convenient sealing ideal for temperature-sensitive pet products. Selecting between heat seal and cold seal Mylar depends on the specific needs for shelf life, ease of use, and product sensitivity.

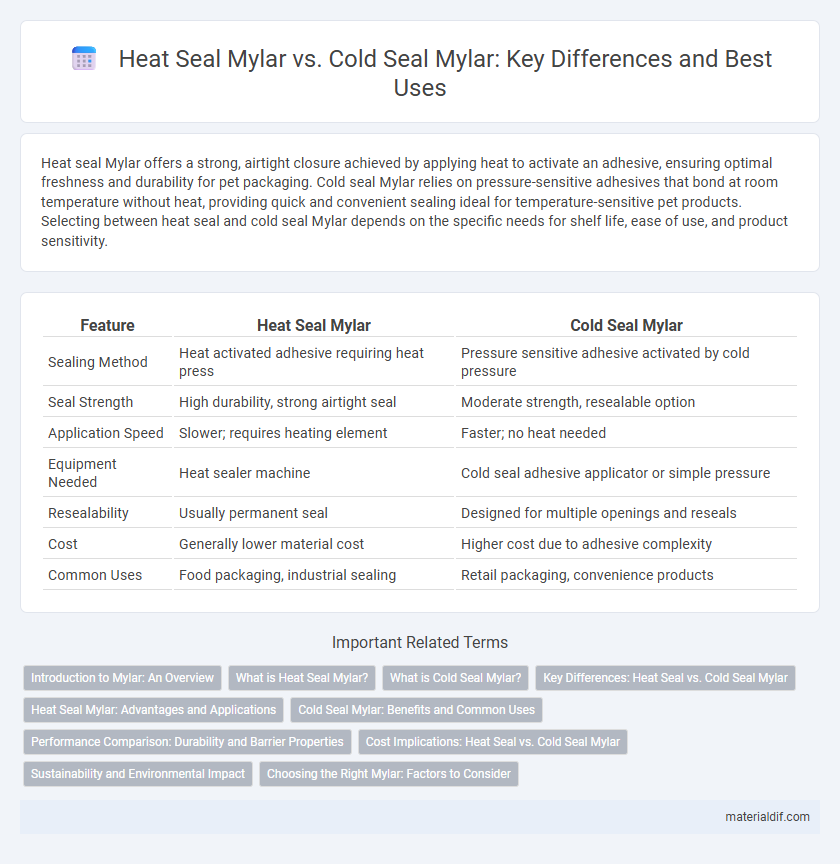

Table of Comparison

| Feature | Heat Seal Mylar | Cold Seal Mylar |

|---|---|---|

| Sealing Method | Heat activated adhesive requiring heat press | Pressure sensitive adhesive activated by cold pressure |

| Seal Strength | High durability, strong airtight seal | Moderate strength, resealable option |

| Application Speed | Slower; requires heating element | Faster; no heat needed |

| Equipment Needed | Heat sealer machine | Cold seal adhesive applicator or simple pressure |

| Resealability | Usually permanent seal | Designed for multiple openings and reseals |

| Cost | Generally lower material cost | Higher cost due to adhesive complexity |

| Common Uses | Food packaging, industrial sealing | Retail packaging, convenience products |

Introduction to Mylar: An Overview

Mylar is a versatile polyester film known for its durability, strength, and excellent barrier properties against moisture, gases, and light. Heat Seal Mylar utilizes heat and pressure to create a secure bond, making it ideal for packaging requiring airtight seals, while Cold Seal Mylar forms seals using pressure-sensitive adhesives without heat, suitable for temperature-sensitive products. Both types of Mylar films offer reliable protection and preservation but differ in their sealing methods to accommodate various industrial applications.

What is Heat Seal Mylar?

Heat Seal Mylar is a polyester film coated with a heat-activated adhesive layer that bonds securely when exposed to controlled temperature and pressure. It offers superior sealing strength and durability, making it ideal for packaging applications requiring tamper resistance and product freshness. This type of Mylar excels in preserving food, pharmaceuticals, and electronics by creating airtight, moisture-resistant seals.

What is Cold Seal Mylar?

Cold Seal Mylar is a type of packaging material coated with an adhesive that bonds securely at room temperature without the need for heat activation. This makes it ideal for fast and efficient sealing processes, especially for products sensitive to heat. Its application is common in food packaging, pharmaceuticals, and confectionery where maintaining product integrity without heat remains crucial.

Key Differences: Heat Seal vs. Cold Seal Mylar

Heat seal Mylar requires the application of heat to activate an adhesive layer, creating a strong, permanent bond ideal for packaging products sensitive to humidity or requiring tamper resistance. Cold seal Mylar uses pressure-sensitive adhesives that bond at room temperature without heat, making it suitable for heat-sensitive items and faster, energy-efficient sealing processes. The choice between heat seal and cold seal Mylar depends on product type, packaging speed, and environmental considerations.

Heat Seal Mylar: Advantages and Applications

Heat Seal Mylar offers superior durability and airtight sealing compared to Cold Seal variants, making it ideal for packaging sensitive products such as food, pharmaceuticals, and electronics. Its heat-activated adhesive ensures a strong, tamper-evident seal that extends shelf life and protects contents from moisture, oxygen, and contaminants. Common applications include snack packaging, medical supplies, and industrial components requiring high-barrier protection and reliable sealing performance.

Cold Seal Mylar: Benefits and Common Uses

Cold Seal Mylar offers a unique adhesive property that activates with pressure rather than heat, making it ideal for packaging heat-sensitive products. Its benefits include easy and noise-free opening, excellent tamper resistance, and compatibility with a variety of substrates, enhancing product preservation and shelf appeal. Common uses of Cold Seal Mylar include wrapping chocolates, medical supplies, and bakery items where maintaining product integrity without heat exposure is crucial.

Performance Comparison: Durability and Barrier Properties

Heat seal Mylar offers superior durability and enhanced barrier properties compared to cold seal Mylar, making it ideal for applications requiring strong, moisture-resistant packaging. Heat seal Mylar forms a permanent bond through heat-activated adhesives, providing greater resistance to punctures and environmental factors. In contrast, cold seal Mylar relies on pressure-sensitive adhesives, offering faster sealing but reduced strength and lower protection against oxygen and moisture infiltration.

Cost Implications: Heat Seal vs. Cold Seal Mylar

Heat seal Mylar generally incurs higher initial costs due to the need for specialized heat sealing equipment and energy consumption, but it offers superior durability and airtight seals, reducing potential product loss and returns. Cold seal Mylar eliminates the energy expense by using pressure-sensitive adhesives, allowing for lower upfront production costs and faster sealing processes, making it cost-effective for packaging sensitive items requiring quick turnaround. Choosing between heat seal and cold seal Mylar depends on balancing upfront machinery investment against ongoing operational costs and packaging performance requirements.

Sustainability and Environmental Impact

Heat seal Mylar offers stronger, more durable seals that reduce packaging waste through improved product protection, leading to less spoilage and landfill contribution. Cold seal Mylar requires less energy during sealing, lowering the carbon footprint in production but may result in weaker seals that increase product loss and environmental burden. Selecting Heat seal or Cold seal Mylar impacts sustainability by balancing energy consumption with waste reduction, highlighting the need for lifecycle assessment to optimize environmental benefits.

Choosing the Right Mylar: Factors to Consider

Choosing the right Mylar depends on the packaging application, with heat seal Mylar offering strong, tamper-evident seals ideal for food and medical products requiring airtight protection. Cold seal Mylar is preferred for heat-sensitive items, providing secure bonding without heat, reducing the risk of damage or deformation. Factors such as product sensitivity, sealing equipment availability, and desired shelf life determine the optimal Mylar type for effective packaging.

Heat Seal Mylar vs Cold Seal Mylar Infographic

materialdif.com

materialdif.com