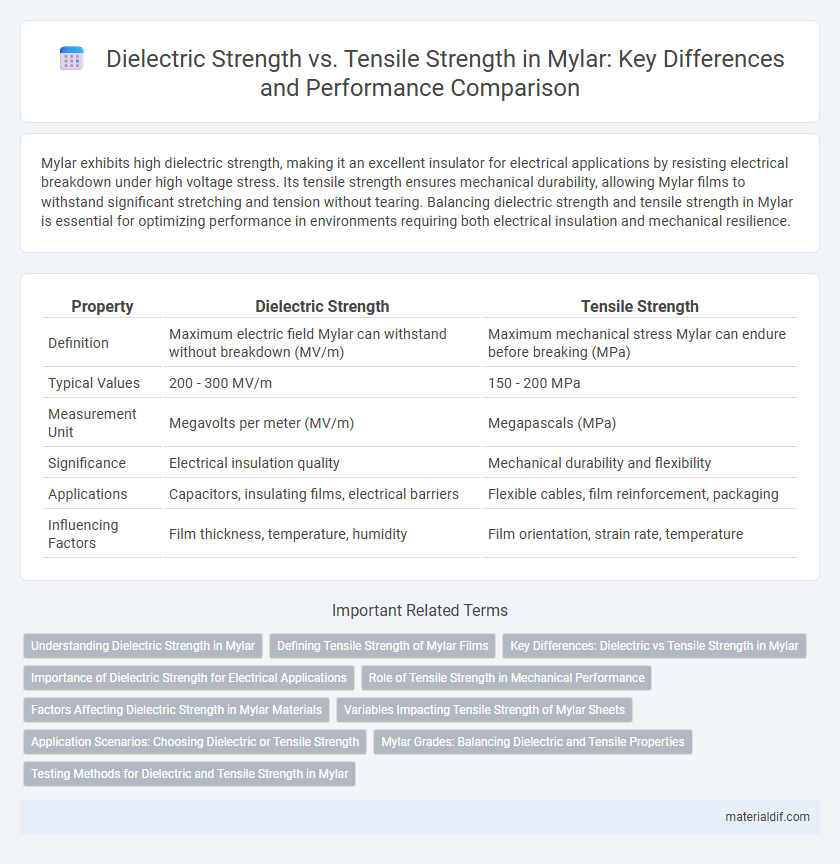

Mylar exhibits high dielectric strength, making it an excellent insulator for electrical applications by resisting electrical breakdown under high voltage stress. Its tensile strength ensures mechanical durability, allowing Mylar films to withstand significant stretching and tension without tearing. Balancing dielectric strength and tensile strength in Mylar is essential for optimizing performance in environments requiring both electrical insulation and mechanical resilience.

Table of Comparison

| Property | Dielectric Strength | Tensile Strength |

|---|---|---|

| Definition | Maximum electric field Mylar can withstand without breakdown (MV/m) | Maximum mechanical stress Mylar can endure before breaking (MPa) |

| Typical Values | 200 - 300 MV/m | 150 - 200 MPa |

| Measurement Unit | Megavolts per meter (MV/m) | Megapascals (MPa) |

| Significance | Electrical insulation quality | Mechanical durability and flexibility |

| Applications | Capacitors, insulating films, electrical barriers | Flexible cables, film reinforcement, packaging |

| Influencing Factors | Film thickness, temperature, humidity | Film orientation, strain rate, temperature |

Understanding Dielectric Strength in Mylar

Dielectric strength in Mylar refers to its ability to withstand high electrical voltages without breaking down, typically measured in kilovolts per millimeter (kV/mm). This property is critical for Mylar's use as an insulating material in capacitors, flexible circuits, and electrical insulation films. While Mylar exhibits high tensile strength, allowing it to resist mechanical stress, its dielectric strength specifically ensures reliable electrical insulation under high-voltage conditions.

Defining Tensile Strength of Mylar Films

Tensile strength of Mylar films measures the maximum stress the material can withstand while being stretched before breaking, typically ranging from 150 to 220 MPa. This property is crucial for applications requiring durability and flexibility, as Mylar's high tensile strength ensures resistance to tearing and mechanical stress. In comparison, dielectric strength of Mylar, usually around 200-300 kV/mm, defines its ability to insulate against electrical breakdown, but tensile strength emphasizes mechanical performance in film applications.

Key Differences: Dielectric vs Tensile Strength in Mylar

Dielectric strength in Mylar measures its ability to withstand electric voltage without breaking down, typically rated around 200-300 kV/mm, whereas tensile strength refers to its mechanical resistance to breaking under tension, usually about 170 MPa. Dielectric strength is critical for insulating applications, ensuring electrical isolation, while tensile strength determines Mylar's durability and flexibility in physical stress conditions. These key differences highlight Mylar's dual functionality as both an excellent electrical insulator and a robust mechanical material.

Importance of Dielectric Strength for Electrical Applications

Dielectric strength in Mylar is crucial for electrical insulation, preventing breakdown under high voltage conditions and ensuring safety and reliability in capacitors and insulating films. While tensile strength measures mechanical durability and flexibility, dielectric strength directly impacts Mylar's performance in protecting electrical components from short circuits and voltage surges. High dielectric strength enables Mylar to be widely used in electronics, medical devices, and aerospace industries where electrical insulation is paramount.

Role of Tensile Strength in Mechanical Performance

Tensile strength in Mylar plays a crucial role in determining its mechanical performance by providing resistance to breaking under tension, which ensures durability and flexibility in applications such as electrical insulation and packaging. While dielectric strength measures Mylar's ability to withstand electric stress without breakdown, tensile strength directly impacts its ability to maintain structural integrity under mechanical loads. High tensile strength in Mylar enables enhanced reliability in environments where both electrical insulation and mechanical robustness are required.

Factors Affecting Dielectric Strength in Mylar Materials

Dielectric strength in Mylar is primarily influenced by its thickness, moisture content, and manufacturing process, with thicker films typically exhibiting higher dielectric breakdown voltage. Contaminants and surface impurities reduce dielectric strength by creating localized electric field enhancements, while tensile strength is more directly related to the molecular orientation and crystallinity during extrusion. Optimizing processing conditions such as stretch ratio and heat treatment can enhance both dielectric and tensile properties, making Mylar suitable for high-performance insulating applications.

Variables Impacting Tensile Strength of Mylar Sheets

Tensile strength of Mylar sheets is influenced by factors such as thickness, molecular orientation, and temperature during processing. Dielectric strength, while critical for electrical insulation, remains relatively stable compared to tensile strength, which can vary significantly with stretching rate and environmental conditions. Variations in crystallinity and humidity levels also directly impact the mechanical durability of Mylar films.

Application Scenarios: Choosing Dielectric or Tensile Strength

Mylar exhibits high dielectric strength, typically around 200-300 kV/mm, making it ideal for electrical insulation applications such as capacitor films and flexible printed circuits. Its tensile strength ranges from 75 to 170 MPa, which supports mechanical durability in packaging and protective layering where physical stress resistance is crucial. Selecting Mylar based on dielectric strength suits high-voltage environments, while prioritizing tensile strength benefits scenarios requiring robust mechanical stability.

Mylar Grades: Balancing Dielectric and Tensile Properties

Mylar grades are engineered to balance dielectric strength and tensile strength, optimizing performance for various industrial applications. Higher-grade Mylar films exhibit dielectric strengths up to 7000 volts per mil, while maintaining tensile strengths around 15,000 psi, ensuring reliable electrical insulation and mechanical durability. Selecting the appropriate Mylar grade involves evaluating the specific dielectric requirements alongside mechanical stress tolerances to achieve maximum efficiency and safety.

Testing Methods for Dielectric and Tensile Strength in Mylar

Testing the dielectric strength of Mylar involves applying a high-voltage electric field between two electrodes to measure the maximum voltage the film can withstand before electrical breakdown. Tensile strength testing is conducted using a universal testing machine that stretches the Mylar film at a controlled rate until it breaks, providing data on its mechanical endurance. Both tests require precise environmental controls and standardized sample preparation to ensure accurate and reproducible results.

Dielectric Strength vs Tensile Strength (in Mylar) Infographic

materialdif.com

materialdif.com