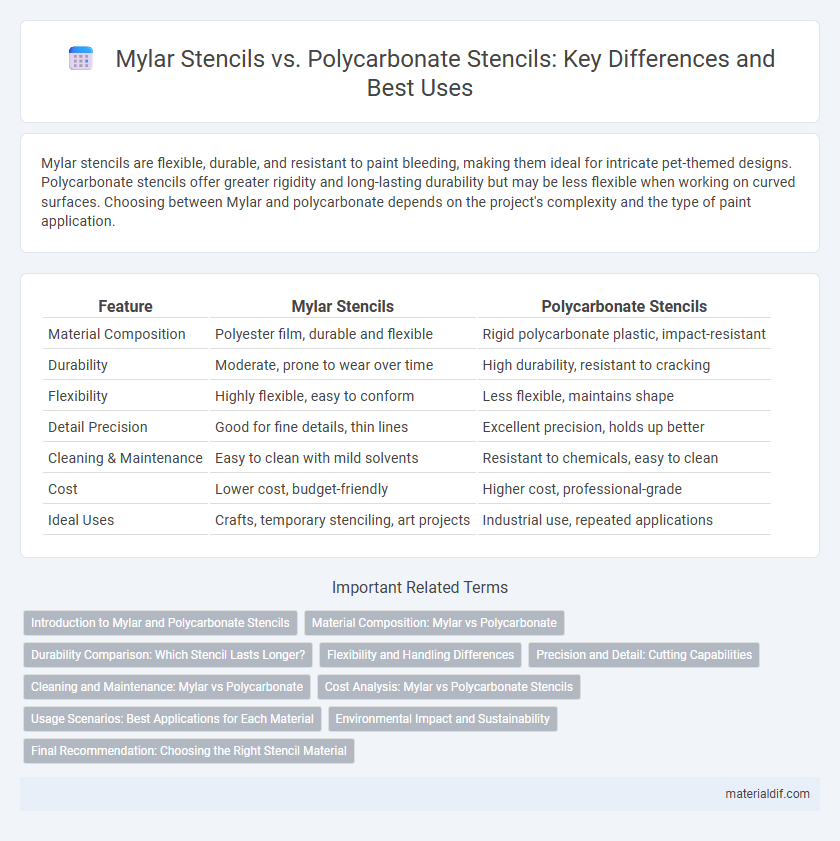

Mylar stencils are flexible, durable, and resistant to paint bleeding, making them ideal for intricate pet-themed designs. Polycarbonate stencils offer greater rigidity and long-lasting durability but may be less flexible when working on curved surfaces. Choosing between Mylar and polycarbonate depends on the project's complexity and the type of paint application.

Table of Comparison

| Feature | Mylar Stencils | Polycarbonate Stencils |

|---|---|---|

| Material Composition | Polyester film, durable and flexible | Rigid polycarbonate plastic, impact-resistant |

| Durability | Moderate, prone to wear over time | High durability, resistant to cracking |

| Flexibility | Highly flexible, easy to conform | Less flexible, maintains shape |

| Detail Precision | Good for fine details, thin lines | Excellent precision, holds up better |

| Cleaning & Maintenance | Easy to clean with mild solvents | Resistant to chemicals, easy to clean |

| Cost | Lower cost, budget-friendly | Higher cost, professional-grade |

| Ideal Uses | Crafts, temporary stenciling, art projects | Industrial use, repeated applications |

Introduction to Mylar and Polycarbonate Stencils

Mylar stencils, made from a durable polyester film, offer high flexibility, excellent detail retention, and resistance to stretching, making them ideal for intricate and reusable stencil designs. Polycarbonate stencils, crafted from a rigid thermoplastic material, provide enhanced durability, resistance to solvents, and superior dimensional stability, which suits more robust applications and repeated use in harsh environments. Both Mylar and polycarbonate stencils serve distinct purposes in crafting, industrial marking, and art projects, with Mylar favored for precision and flexibility, while polycarbonate excels in toughness and chemical resistance.

Material Composition: Mylar vs Polycarbonate

Mylar stencils are crafted from polyester film, known for its flexibility, durability, and resistance to chemicals and heat, making it ideal for detailed and reusable designs. Polycarbonate stencils, made from a thermoplastic polymer, offer superior rigidity and impact resistance but less flexibility compared to Mylar. The choice between Mylar and polycarbonate depends on the application needs, with Mylar providing easier handling and fine precision, while polycarbonate excels in heavy-duty, repetitive use.

Durability Comparison: Which Stencil Lasts Longer?

Mylar stencils exhibit superior durability compared to polycarbonate stencils due to their resistance to cracking, tearing, and chemical damage during repeated use. Their flexible yet strong polyester composition allows for extended lifespan in various crafting and industrial applications. In contrast, polycarbonate stencils tend to wear faster under heavy use, making Mylar the preferred choice for long-term stencil durability.

Flexibility and Handling Differences

Mylar stencils offer superior flexibility compared to polycarbonate stencils, allowing for easier application on curved or uneven surfaces without cracking. This material's lightweight nature improves handling during detailed projects, making it ideal for intricate designs and repeated use. In contrast, polycarbonate stencils provide rigidity and durability but can be less adaptable, often requiring more careful positioning to avoid breakage.

Precision and Detail: Cutting Capabilities

Mylar stencils offer superior precision and intricate detail due to their thin, flexible material, allowing for sharper and more accurate cuts compared to polycarbonate stencils. Polycarbonate stencils, while more rigid and durable, often lack the fine cutting capabilities necessary for highly detailed designs. For applications requiring intricate patterns and exactness, Mylar stencils provide unmatched cutting resolution and edge clarity.

Cleaning and Maintenance: Mylar vs Polycarbonate

Mylar stencils offer superior ease of cleaning due to their smooth, non-porous surface that resists ink and paint buildup, enabling quick removal with mild soap and water. Polycarbonate stencils tend to require more intensive cleaning, often needing stronger solvents to remove residue, which can degrade the material over time. The durability of Mylar against frequent washings enhances its maintenance efficiency compared to the more chemically sensitive polycarbonate.

Cost Analysis: Mylar vs Polycarbonate Stencils

Mylar stencils typically offer a more cost-effective solution compared to polycarbonate stencils due to lower material and manufacturing expenses. Polycarbonate stencils provide greater durability and chemical resistance, but their higher upfront cost can impact budget considerations for large or repetitive stencil projects. Evaluating the balance between initial investment and stencil lifespan is crucial for optimizing overall cost efficiency in applications like screen printing or electronics.

Usage Scenarios: Best Applications for Each Material

Mylar stencils excel in fine-detail applications such as airbrushing and fabric painting due to their flexibility and ability to hold sharp, intricate designs. Polycarbonate stencils are preferred for heavy-duty uses like industrial marking and repeated use on rough surfaces because of their durability and resistance to wear. Choosing between Mylar and polycarbonate depends on the project requirements, with Mylar favoring precision and delicate tasks, while polycarbonate suits repetitive, robust operations.

Environmental Impact and Sustainability

Mylar stencils offer significant environmental advantages over polycarbonate stencils due to their recyclability and lower carbon footprint during production. Made from polyethylene terephthalate (PET), Mylar is biodegradable under specific industrial conditions, reducing long-term waste. In contrast, polycarbonate stencils, derived from petroleum-based plastics, contribute more to environmental pollution and have limited recycling options, making Mylar a more sustainable choice for eco-conscious creators.

Final Recommendation: Choosing the Right Stencil Material

Mylar stencils offer superior flexibility, durability, and resistance to solvents, making them ideal for intricate designs and repeated use in various crafting and industrial applications. Polycarbonate stencils provide high impact resistance and rigidity, suitable for projects requiring sturdier, reusable templates but may wear faster with chemical exposure. For precision work demanding longevity and delicate detailing, Mylar stencils are the recommended choice, while polycarbonate fits better for rougher, heavy-duty tasks.

Mylar Stencils vs Polycarbonate Stencils Infographic

materialdif.com

materialdif.com