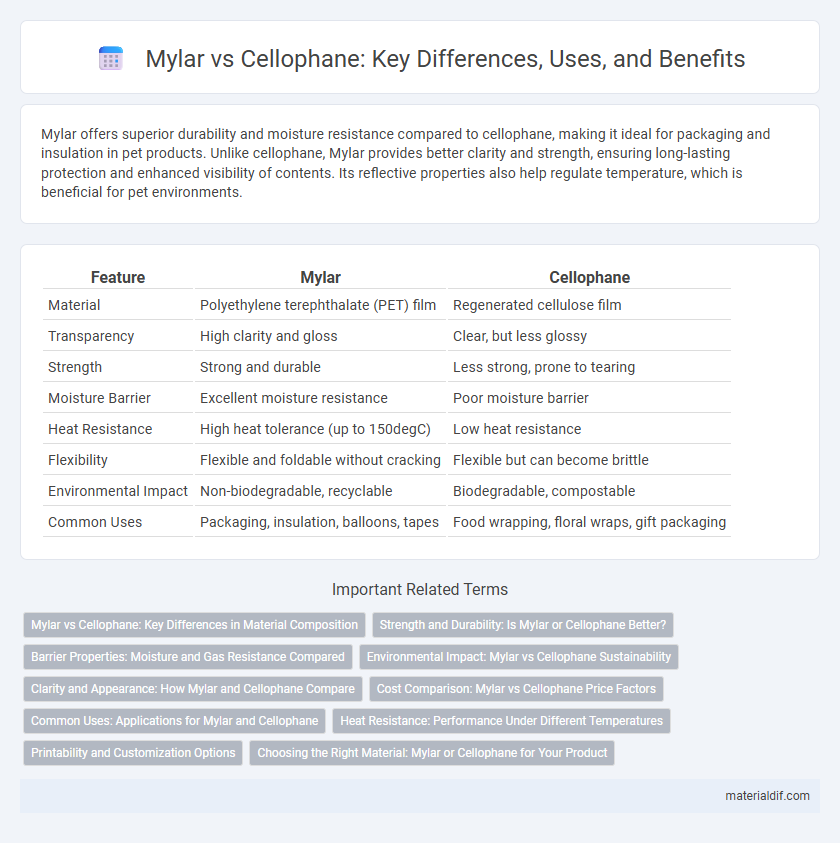

Mylar offers superior durability and moisture resistance compared to cellophane, making it ideal for packaging and insulation in pet products. Unlike cellophane, Mylar provides better clarity and strength, ensuring long-lasting protection and enhanced visibility of contents. Its reflective properties also help regulate temperature, which is beneficial for pet environments.

Table of Comparison

| Feature | Mylar | Cellophane |

|---|---|---|

| Material | Polyethylene terephthalate (PET) film | Regenerated cellulose film |

| Transparency | High clarity and gloss | Clear, but less glossy |

| Strength | Strong and durable | Less strong, prone to tearing |

| Moisture Barrier | Excellent moisture resistance | Poor moisture barrier |

| Heat Resistance | High heat tolerance (up to 150degC) | Low heat resistance |

| Flexibility | Flexible and foldable without cracking | Flexible but can become brittle |

| Environmental Impact | Non-biodegradable, recyclable | Biodegradable, compostable |

| Common Uses | Packaging, insulation, balloons, tapes | Food wrapping, floral wraps, gift packaging |

Mylar vs Cellophane: Key Differences in Material Composition

Mylar is a polyester film composed primarily of polyethylene terephthalate (PET), known for its durability, flexibility, and resistance to moisture and chemicals. In contrast, cellophane is made from regenerated cellulose derived from wood pulp, making it biodegradable but less resistant to moisture and tearing. These material composition differences result in Mylar being preferred for long-lasting packaging and insulation applications, while cellophane is commonly used for eco-friendly wrapping and lightweight protective covers.

Strength and Durability: Is Mylar or Cellophane Better?

Mylar, a polyester film, offers superior strength and durability compared to cellophane, which is a cellulose-based film. Mylar resists tearing, moisture, and temperature changes, making it ideal for long-term storage and packaging. Cellophane, while biodegradable, lacks the tensile strength and moisture barrier properties that Mylar provides for more demanding applications.

Barrier Properties: Moisture and Gas Resistance Compared

Mylar exhibits superior moisture and gas barrier properties compared to cellophane, making it highly effective for packaging sensitive products. Its polyester composition provides low permeability to oxygen and water vapor, ensuring longer shelf life and product freshness. Cellophane, being cellulose-based, offers moderate moisture resistance but is less effective against gas transmission, limiting its use in high-barrier applications.

Environmental Impact: Mylar vs Cellophane Sustainability

Mylar, a polyester film, offers greater durability and recyclability compared to cellophane, which is made from cellulose derived from plants but is biodegradable under industrial composting conditions. Mylar's production has a higher carbon footprint due to petrochemical processing, yet its longevity reduces the need for frequent replacement, contributing to less waste. Cellophane's renewable origin favors sustainability, but its limited durability and reliance on energy-intensive composting challenge its overall environmental impact.

Clarity and Appearance: How Mylar and Cellophane Compare

Mylar offers superior clarity with a glossy, smooth surface that enhances visual appeal, making images and colors appear more vibrant compared to cellophane's slightly matte and less transparent finish. Cellophane tends to have a natural, organic texture that can cause slight visual distortion, while Mylar provides consistent transparency ideal for high-quality packaging and display applications. The durability and resistance to moisture in Mylar further preserve its clarity and appearance over time, unlike cellophane which can yellow or become brittle.

Cost Comparison: Mylar vs Cellophane Price Factors

Mylar generally costs more than cellophane due to its polyester base, which provides superior durability and moisture resistance. Cellophane is cheaper because it is made from cellulose and is less durable, making it suitable for short-term applications. Price factors for Mylar include production complexity and enhanced protective properties, while cellophane's lower price reflects its biodegradability and easier manufacturing process.

Common Uses: Applications for Mylar and Cellophane

Mylar is widely used in insulation, packaging, and protective coverings due to its durability and heat resistance, while cellophane is primarily applied in food wrapping and gift packaging thanks to its biodegradability and moisture permeability. Mylar's reflective properties make it ideal for emergency blankets, balloons, and electrical insulation, whereas cellophane is favored for its clarity and breathability in preserving freshness of flowers and confectionery. Both materials serve important roles in packaging, but Mylar excels in industrial and thermal applications, whereas cellophane is preferred for environmentally friendly, breathable packaging solutions.

Heat Resistance: Performance Under Different Temperatures

Mylar exhibits superior heat resistance compared to cellophane, maintaining structural integrity and clarity at temperatures up to approximately 150degC, while cellophane tends to degrade or shrink around 100degC. The polyester composition of Mylar allows it to endure higher thermal stress without curling or melting, making it ideal for applications exposed to elevated temperatures such as insulation or thermal insulation barriers. Cellophane's cellulose base limits its performance under heat, causing loss of mechanical strength and transparency, which restricts its use in high-temperature environments.

Printability and Customization Options

Mylar offers superior printability compared to cellophane due to its smooth, non-porous surface that allows for high-resolution graphics and vibrant colors. Unlike cellophane, Mylar supports a wider range of customization options including lamination, metalization, and various finishes that enhance both aesthetic appeal and durability. These properties make Mylar the preferred choice for packaging and promotional materials requiring detailed designs and long-lasting visual impact.

Choosing the Right Material: Mylar or Cellophane for Your Product

Mylar offers superior durability, moisture resistance, and clarity compared to cellophane, making it ideal for long-term packaging and protection. Cellophane is biodegradable and more environmentally friendly, suited for short-term use and products emphasizing sustainability. Selecting between Mylar or cellophane depends on whether durability and barrier properties or eco-friendliness and compostability are the primary requirements for your product packaging.

Mylar vs Cellophane Infographic

materialdif.com

materialdif.com