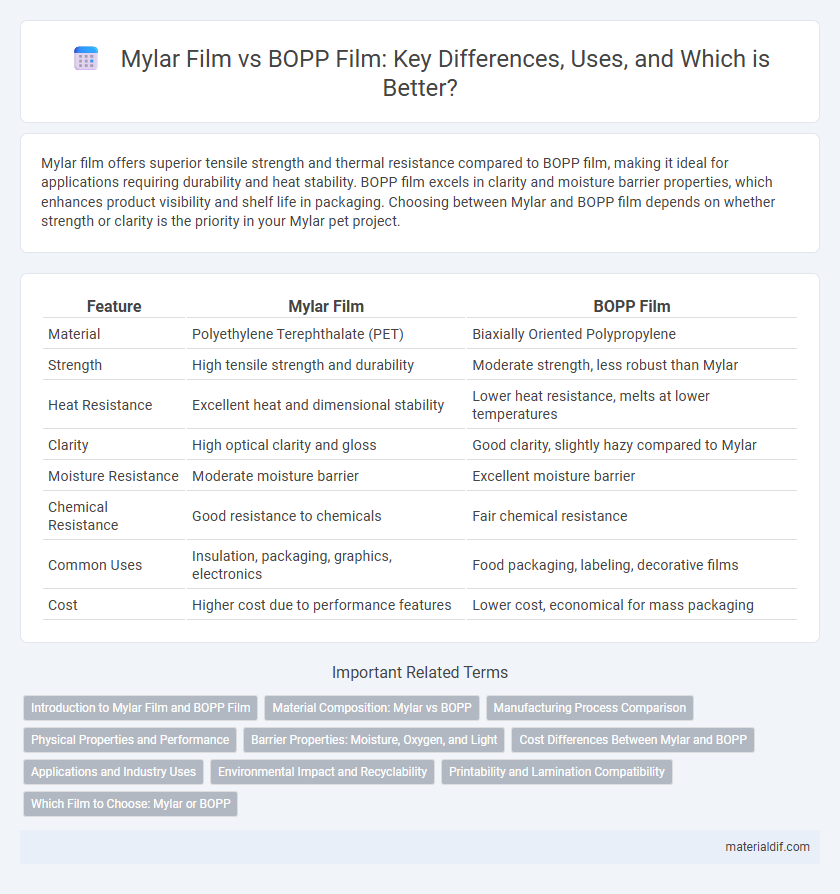

Mylar film offers superior tensile strength and thermal resistance compared to BOPP film, making it ideal for applications requiring durability and heat stability. BOPP film excels in clarity and moisture barrier properties, which enhances product visibility and shelf life in packaging. Choosing between Mylar and BOPP film depends on whether strength or clarity is the priority in your Mylar pet project.

Table of Comparison

| Feature | Mylar Film | BOPP Film |

|---|---|---|

| Material | Polyethylene Terephthalate (PET) | Biaxially Oriented Polypropylene |

| Strength | High tensile strength and durability | Moderate strength, less robust than Mylar |

| Heat Resistance | Excellent heat and dimensional stability | Lower heat resistance, melts at lower temperatures |

| Clarity | High optical clarity and gloss | Good clarity, slightly hazy compared to Mylar |

| Moisture Resistance | Moderate moisture barrier | Excellent moisture barrier |

| Chemical Resistance | Good resistance to chemicals | Fair chemical resistance |

| Common Uses | Insulation, packaging, graphics, electronics | Food packaging, labeling, decorative films |

| Cost | Higher cost due to performance features | Lower cost, economical for mass packaging |

Introduction to Mylar Film and BOPP Film

Mylar film is a polyester film known for its high tensile strength, dimensional stability, and excellent clarity, making it ideal for electrical insulation, packaging, and printing applications. BOPP film, or biaxially oriented polypropylene, offers superior moisture resistance, high gloss, and good barrier properties, widely used in food packaging and labeling. Both films serve distinct purposes, with Mylar excelling in durability and thermal resistance, while BOPP is favored for cost-effective, moisture-resistant packaging solutions.

Material Composition: Mylar vs BOPP

Mylar film is made from stretched polyethylene terephthalate (PET), offering high tensile strength, chemical stability, and excellent dimensional stability. BOPP (Biaxially Oriented Polypropylene) film, composed of polypropylene, provides superior moisture resistance and clarity but lower heat resistance compared to Mylar. The distinct material compositions of Mylar and BOPP define their optimal applications in packaging, insulation, and industrial uses.

Manufacturing Process Comparison

Mylar film is produced through a biaxial orientation process where polyethylene terephthalate (PET) molten resin is stretched both longitudinally and transversely to enhance mechanical properties and clarity. BOPP film manufacturing involves the biaxial orientation of polypropylene resin using a tenter frame or sequential stretching method to improve tensile strength and gloss. The PET base of Mylar ensures superior thermal stability and gas barrier performance compared to the polypropylene base of BOPP, influencing process parameters such as extrusion temperature and stretching ratios.

Physical Properties and Performance

Mylar film, made from biaxially-oriented polyethylene terephthalate (BoPET), exhibits superior tensile strength, clarity, and dimensional stability compared to BOPP film, which is biaxially-oriented polypropylene. Mylar offers higher heat resistance and better barrier properties against moisture and gases, making it ideal for applications requiring durability and long-lasting protection. BOPP film, however, provides excellent printability and cost-effectiveness but generally lacks the mechanical strength and thermal stability characteristic of Mylar.

Barrier Properties: Moisture, Oxygen, and Light

Mylar film exhibits superior barrier properties against moisture, oxygen, and light compared to BOPP film, making it ideal for packaging applications requiring long shelf life and product protection. Its polyester base provides excellent resistance to water vapor and oxygen permeation, significantly reducing the risk of spoilage or contamination. While BOPP film offers good clarity and moisture barrier, it lacks the high oxygen and light barrier properties that Mylar reliably delivers.

Cost Differences Between Mylar and BOPP

Mylar film generally incurs higher production costs due to its polyester base, which offers superior strength, clarity, and temperature resistance compared to the polypropylene structure of BOPP film. BOPP film is more economical for large-scale packaging applications, providing cost savings through faster production rates and lower raw material expenses. When evaluating cost differences, Mylar is preferred for premium or performance-critical uses despite its higher price, while BOPP is favored for budget-conscious, high-volume packaging solutions.

Applications and Industry Uses

Mylar film, known for its exceptional tensile strength, clarity, and heat resistance, is widely used in electronics, packaging, and insulation applications, especially where durability and moisture barrier properties are critical. BOPP film, characterized by its superior stiffness, gloss, and printability, is predominantly utilized in food packaging, labeling, and lamination industries due to its cost-effectiveness and excellent moisture resistance. Both films serve complementary roles in packaging sectors, with Mylar favored in high-performance and protective uses, while BOPP dominates flexible packaging and decorative applications.

Environmental Impact and Recyclability

Mylar film, made from biaxially oriented polyethylene terephthalate (BoPET), offers superior recyclability compared to BOPP film, which is derived from polypropylene and has more limited recycling options due to its polystyrene contamination. The environmental impact of Mylar is lower as it is more durable, reducing waste by extending product lifespan, and it can be recycled into polyester fibers, reducing landfill contributions. Conversely, BOPP film decomposes slower and often requires specialized facilities for recycling, increasing its environmental footprint.

Printability and Lamination Compatibility

Mylar film, made from biaxially oriented polyethylene terephthalate (BoPET), offers superior printability due to its smooth surface and excellent dimensional stability, ensuring high-resolution graphics and vibrant colors. In contrast, BOPP film, composed of biaxially oriented polypropylene, provides good printability but generally lags behind Mylar in ink adhesion and clarity. Mylar's compatibility with various lamination adhesives results in stronger, more durable laminates compared to BOPP, which may face challenges bonding uniformly with certain adhesives, affecting overall lamination quality.

Which Film to Choose: Mylar or BOPP

Mylar film offers superior tensile strength, heat resistance, and dimensional stability, making it ideal for applications requiring durability and high performance, such as electrical insulation and magnetic tape. BOPP film excels in clarity, moisture resistance, and cost-effectiveness, commonly used for packaging and labeling where transparency and affordability are priorities. Choosing Mylar or BOPP film depends on specific requirements: opt for Mylar for thermal and mechanical robustness, while BOPP suits projects prioritizing visual appeal and economic efficiency.

Mylar Film vs BOPP Film Infographic

materialdif.com

materialdif.com