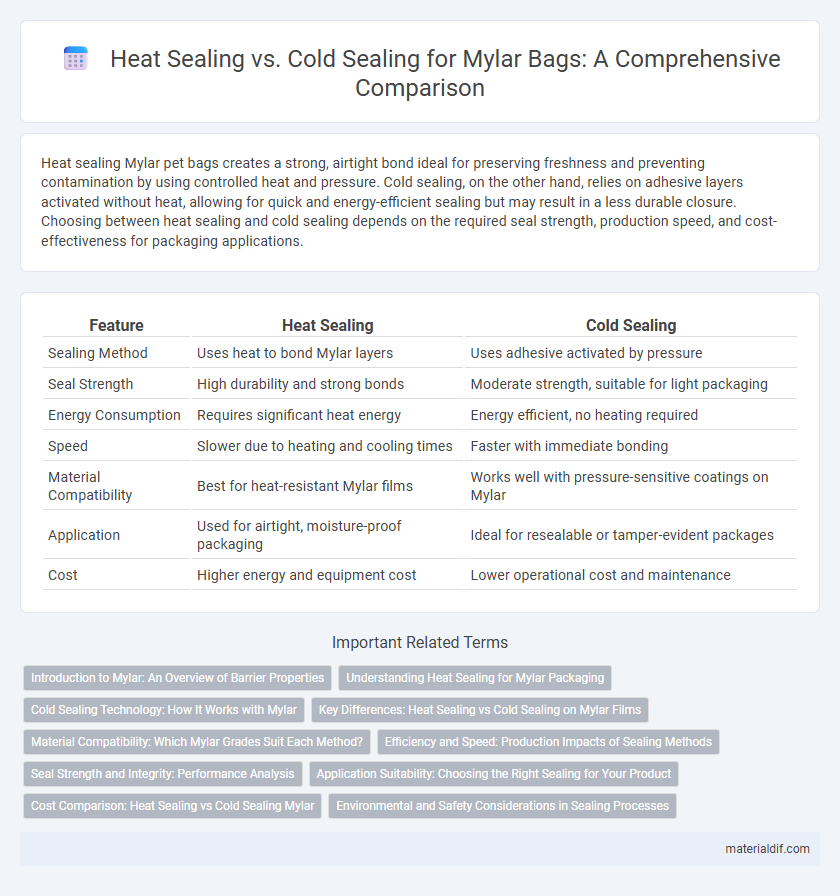

Heat sealing Mylar pet bags creates a strong, airtight bond ideal for preserving freshness and preventing contamination by using controlled heat and pressure. Cold sealing, on the other hand, relies on adhesive layers activated without heat, allowing for quick and energy-efficient sealing but may result in a less durable closure. Choosing between heat sealing and cold sealing depends on the required seal strength, production speed, and cost-effectiveness for packaging applications.

Table of Comparison

| Feature | Heat Sealing | Cold Sealing |

|---|---|---|

| Sealing Method | Uses heat to bond Mylar layers | Uses adhesive activated by pressure |

| Seal Strength | High durability and strong bonds | Moderate strength, suitable for light packaging |

| Energy Consumption | Requires significant heat energy | Energy efficient, no heating required |

| Speed | Slower due to heating and cooling times | Faster with immediate bonding |

| Material Compatibility | Best for heat-resistant Mylar films | Works well with pressure-sensitive coatings on Mylar |

| Application | Used for airtight, moisture-proof packaging | Ideal for resealable or tamper-evident packages |

| Cost | Higher energy and equipment cost | Lower operational cost and maintenance |

Introduction to Mylar: An Overview of Barrier Properties

Mylar is a strong polyester film known for its excellent barrier properties, including resistance to moisture, gases, and chemicals, making it ideal for protective packaging. Heat sealing Mylar involves applying heat and pressure to create a durable, airtight bond, enhancing its moisture and oxygen barrier performance. Cold sealing uses adhesive layers at room temperature, providing convenience and safety but typically offers lower barrier integrity compared to heat-sealed Mylar.

Understanding Heat Sealing for Mylar Packaging

Heat sealing for Mylar packaging involves using controlled heat and pressure to create a strong, airtight bond by melting the inner layers of the film. Mylar's polyester composition provides excellent thermal resistance, allowing precise temperature settings around 120-180degC to ensure optimal seal integrity without degrading the material. This method ensures superior barrier properties, preserving product freshness and extending shelf life compared to cold sealing techniques.

Cold Sealing Technology: How It Works with Mylar

Cold sealing technology with Mylar involves laminating a pressure-sensitive adhesive layer that activates without heat, ensuring quick and secure sealing. This process preserves Mylar's reflective and moisture-resistant properties by eliminating the need for heat, making it ideal for heat-sensitive products or packaging. Cold sealing enhances packaging efficiency by providing strong, tamper-evident seals while maintaining the integrity and appearance of Mylar films.

Key Differences: Heat Sealing vs Cold Sealing on Mylar Films

Heat sealing Mylar films involves applying heat and pressure to activate the film's adhesive, creating a strong, permanent bond ideal for high-strength packaging applications. Cold sealing Mylar uses pressure-sensitive adhesives that bond at room temperature without heat, reducing energy consumption and enabling sealing of heat-sensitive products. Key differences include the temperature requirement, bonding strength, and suitability for specific products, with heat sealing offering greater durability while cold sealing provides faster, safer sealing for delicate materials.

Material Compatibility: Which Mylar Grades Suit Each Method?

Mylar grades designed for heat sealing typically feature coatings like polyethylene or polyolefin that melt and bond under elevated temperatures, making them compatible with standard heat sealers. In contrast, cold sealing Mylar often includes pressure-sensitive adhesives or specialized coatings that activate at room temperature without heat, suited for applications requiring low thermal exposure. Selecting the appropriate Mylar grade depends on the packaging process and product sensitivity, with heat-sealable Mylar favored for robust seal integrity and cold-sealable variants optimized for delicate or heat-sensitive contents.

Efficiency and Speed: Production Impacts of Sealing Methods

Heat sealing Mylar films offers superior bond strength and faster sealing speeds, significantly enhancing production efficiency in high-volume manufacturing environments. Cold sealing provides the advantage of immediate handling without cooling time, reducing cycle time in applications requiring quick package turnover but generally operates at slower sealing rates compared to heat sealing. Choosing between heat and cold sealing methods directly impacts throughput, energy consumption, and overall operational costs in Mylar packaging processes.

Seal Strength and Integrity: Performance Analysis

Heat sealing of Mylar films provides superior seal strength and integrity due to the thermal bonding process, which creates a uniform and durable seal capable of withstanding high stress and temperature variations. Cold sealing relies on pressure-sensitive adhesives that often result in weaker seals prone to premature failure and reduced barrier properties, especially under harsh environmental conditions. Performance analysis indicates heat sealing is optimal for applications demanding robust, long-lasting seals, while cold sealing suits quick, low-temperature packaging needs with moderate seal strength requirements.

Application Suitability: Choosing the Right Sealing for Your Product

Heat sealing offers strong, durable bonds ideal for packaging products requiring airtight or watertight protection, such as food and pharmaceuticals. Cold sealing is suitable for heat-sensitive items and applications needing quick, low-temperature sealing, commonly used for confectionery and delicate electronics. Selecting the right sealing method depends on the product's thermal sensitivity, packaging material, and required seal integrity to ensure optimal preservation and performance.

Cost Comparison: Heat Sealing vs Cold Sealing Mylar

Heat sealing Mylar typically incurs higher energy costs due to the required elevated temperatures, while cold sealing reduces energy consumption by using pressure-sensitive adhesives. Initial equipment investment for heat sealing machines is generally lower, but ongoing operational expenses may exceed those of cold seal systems. Cold sealing offers cost savings in production speed and lower maintenance, making it economically advantageous for high-volume packaging with Mylar films.

Environmental and Safety Considerations in Sealing Processes

Heat sealing Mylar utilizes controlled high temperatures to bond materials, which may increase energy consumption and emissions, raising environmental concerns. Cold sealing employs adhesive layers activated by pressure, reducing energy use and minimizing hazardous emissions, thus improving workplace safety and environmental impact. Both methods require careful material handling to prevent exposure to harmful substances and ensure sustainable packaging solutions.

Heat Sealing vs Cold Sealing Infographic

materialdif.com

materialdif.com