Mylar tape offers superior temperature resistance and excellent electrical insulation compared to PTFE tape, making it ideal for high-temperature applications in electronics and electrical insulation. PTFE tape provides better chemical resistance and is commonly used for sealing pipe threads and preventing leaks due to its non-stick properties. Choosing between Mylar and PTFE tape depends on the specific requirements of heat tolerance, electrical insulation, and chemical exposure in your project.

Table of Comparison

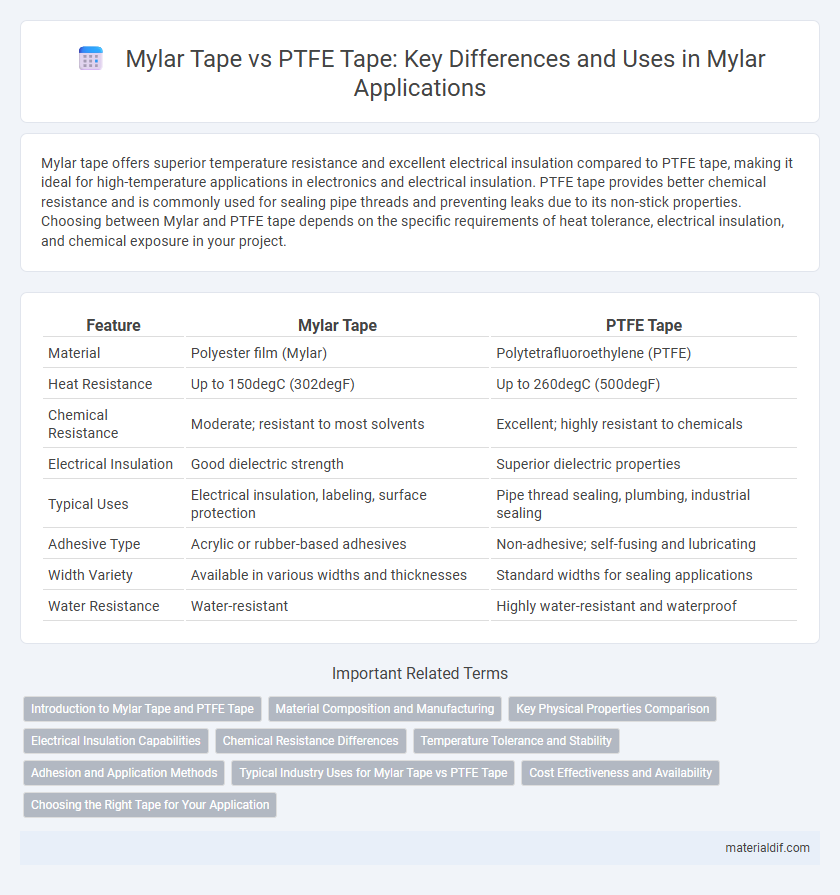

| Feature | Mylar Tape | PTFE Tape |

|---|---|---|

| Material | Polyester film (Mylar) | Polytetrafluoroethylene (PTFE) |

| Heat Resistance | Up to 150degC (302degF) | Up to 260degC (500degF) |

| Chemical Resistance | Moderate; resistant to most solvents | Excellent; highly resistant to chemicals |

| Electrical Insulation | Good dielectric strength | Superior dielectric properties |

| Typical Uses | Electrical insulation, labeling, surface protection | Pipe thread sealing, plumbing, industrial sealing |

| Adhesive Type | Acrylic or rubber-based adhesives | Non-adhesive; self-fusing and lubricating |

| Width Variety | Available in various widths and thicknesses | Standard widths for sealing applications |

| Water Resistance | Water-resistant | Highly water-resistant and waterproof |

Introduction to Mylar Tape and PTFE Tape

Mylar tape is a polyester film known for its high tensile strength, electrical insulation properties, and resistance to heat and chemicals, making it ideal for electrical and mechanical applications. PTFE tape, also called Teflon tape, is a fluoropolymer film primarily used as a thread sealant in plumbing due to its excellent chemical resistance and non-stick properties. Both tapes serve specialized purposes, with Mylar tape excelling in insulation and structural support, while PTFE tape ensures leak-proof seals in pipe fittings.

Material Composition and Manufacturing

Mylar tape consists of biaxially-oriented polyethylene terephthalate (PET) film coated with adhesives, providing excellent tensile strength and chemical resistance, while PTFE tape is made from polytetrafluoroethylene, known for its exceptional non-stick properties and high-temperature tolerance. The manufacturing of Mylar tape involves stretching PET film to align polymer chains, enhancing durability and stability, whereas PTFE tape is typically produced by skiving thin layers from PTFE rods or extrusion, resulting in a flexible, low-friction material. Differences in material composition and production methods lead to distinct performance characteristics, making Mylar tape suited for electrical insulation and protection, while PTFE tape excels in sealing pipe threads and resisting high temperatures.

Key Physical Properties Comparison

Mylar tape offers superior tensile strength and dimensional stability compared to PTFE tape, making it ideal for applications requiring durability and resistance to stretching. PTFE tape excels in chemical resistance and has a lower coefficient of friction, which provides excellent non-stick properties and high-temperature tolerance up to 260degC (500degF). While Mylar tape typically withstands temperatures up to 150degC (302degF), its electrical insulation properties and resistance to moisture make it preferable for electrical and insulation uses.

Electrical Insulation Capabilities

Mylar tape exhibits superior electrical insulation capabilities compared to PTFE tape due to its high dielectric strength and excellent resistance to electrical breakdown. It maintains stable insulation properties across a wide temperature range, ensuring reliable performance in demanding electrical applications. PTFE tape, while chemically inert and thermally resistant, generally offers lower dielectric strength, making Mylar tape preferable for high-voltage insulation needs.

Chemical Resistance Differences

Mylar tape offers superior chemical resistance to a wide range of solvents, acids, and alkalis compared to PTFE tape, making it ideal for harsh chemical environments. PTFE tape resists many chemicals but can degrade when exposed to strong bases and certain solvents over time. The high chemical stability of Mylar tape ensures consistent performance in applications requiring durable, long-term protection against aggressive substances.

Temperature Tolerance and Stability

Mylar tape withstands temperatures up to 150degC with excellent dimensional stability, making it suitable for moderate thermal environments. PTFE tape offers superior temperature tolerance, enduring continuous exposure up to 260degC and short bursts up to 280degC without degrading. The enhanced thermal resistance and chemical inertness of PTFE tape make it ideal for applications requiring long-term stability under extreme heat conditions.

Adhesion and Application Methods

Mylar tape offers superior adhesion on smooth and curved surfaces, making it ideal for electrical insulation and surface protection applications, while PTFE tape provides non-stick properties with moderate adhesion, primarily used for sealing and gasketing in plumbing and industrial settings. Application of Mylar tape involves careful alignment and pressure-sensitive adhesive activation for lasting bond strength, whereas PTFE tape is typically wrapped around threaded joints to create a leak-resistant seal without adhesive. The choice between Mylar and PTFE tape depends on whether strong, permanent adhesion or a flexible, non-adhesive sealing solution is required.

Typical Industry Uses for Mylar Tape vs PTFE Tape

Mylar tape is widely used in electrical insulation, motor wrapping, and thermal insulation due to its high tensile strength, chemical resistance, and excellent dielectric properties. PTFE tape, often known as plumber's tape, is primarily utilized for sealing pipe threads in plumbing to prevent leaks and ensure airtight connections because of its low friction and high chemical inertness. Industrial applications favor Mylar tape for electrical and thermal management, while PTFE tape dominates in fluid sealing and mechanical assembly tasks.

Cost Effectiveness and Availability

Mylar tape offers superior cost-effectiveness compared to PTFE tape due to its lower material costs and longer lifespan, reducing replacement frequency. It is widely available in industrial supply stores and online marketplaces, making procurement straightforward for various applications. PTFE tape, while common, tends to be more expensive and less durable, impacting overall cost efficiency and availability in specialized sizes.

Choosing the Right Tape for Your Application

Mylar tape offers high tensile strength, chemical resistance, and excellent electrical insulation, making it ideal for applications requiring durability and thermal stability. PTFE tape provides superior non-stick properties and chemical inertness, often used for sealing pipe threads and preventing leaks in plumbing or gas fittings. Selecting the right tape depends on whether your application demands mechanical strength and heat resistance (Mylar) or chemical resistance and sealing capability (PTFE).

Mylar Tape vs PTFE Tape Infographic

materialdif.com

materialdif.com