Mylar wrapping offers superior durability and moisture resistance compared to traditional foil wrapping, making it ideal for long-term pet food storage. Unlike foil, Mylar is puncture-resistant and provides an excellent barrier against oxygen and light, preserving freshness and nutritional value. This makes Mylar wrapping a more reliable choice for maintaining the quality of pet products over time.

Table of Comparison

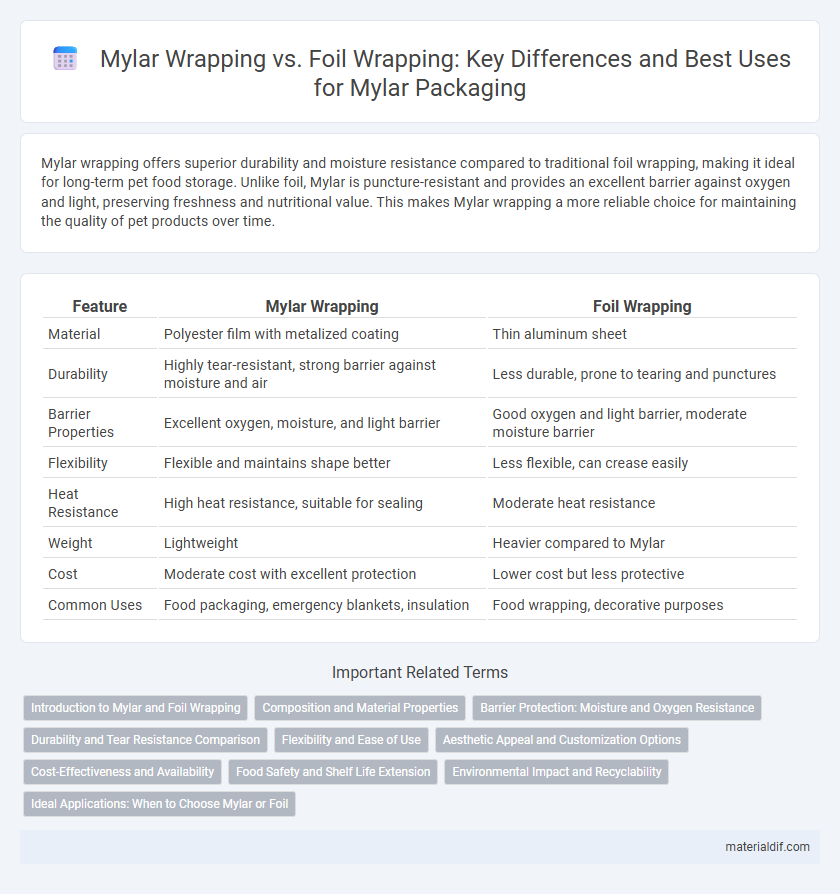

| Feature | Mylar Wrapping | Foil Wrapping |

|---|---|---|

| Material | Polyester film with metalized coating | Thin aluminum sheet |

| Durability | Highly tear-resistant, strong barrier against moisture and air | Less durable, prone to tearing and punctures |

| Barrier Properties | Excellent oxygen, moisture, and light barrier | Good oxygen and light barrier, moderate moisture barrier |

| Flexibility | Flexible and maintains shape better | Less flexible, can crease easily |

| Heat Resistance | High heat resistance, suitable for sealing | Moderate heat resistance |

| Weight | Lightweight | Heavier compared to Mylar |

| Cost | Moderate cost with excellent protection | Lower cost but less protective |

| Common Uses | Food packaging, emergency blankets, insulation | Food wrapping, decorative purposes |

Introduction to Mylar and Foil Wrapping

Mylar wrapping utilizes a polyester film known for its durability, moisture resistance, and ability to create airtight seals, making it ideal for food preservation and insulation purposes. Foil wrapping, typically made from aluminum, provides excellent heat reflection and barrier properties against light, oxygen, and moisture, but it is more prone to tearing compared to Mylar. Both materials serve as effective barriers with specific benefits depending on the application, with Mylar favored for long-term storage due to its strength and flexibility.

Composition and Material Properties

Mylar wrapping consists of biaxially-oriented polyethylene terephthalate (BoPET), offering exceptional tensile strength, chemical stability, and resistance to moisture, gases, and UV light. Foil wrapping, typically made from thin sheets of aluminum, provides excellent thermal conductivity and impermeability but lacks the flexibility and tear resistance found in Mylar films. The polymeric structure of Mylar ensures durability and insulative properties, making it ideal for long-term preservation compared to the metallic composition of foil which excels in heat retention and barrier protection in short-term applications.

Barrier Protection: Moisture and Oxygen Resistance

Mylar wrapping offers superior barrier protection against moisture and oxygen compared to traditional foil wrapping, due to its multi-layer polyester film composition with metalized coating. This enhanced resistance preserves product freshness by preventing oxygen infiltration and moisture loss more effectively. Foil wrapping, while providing some barrier benefits, typically lacks the combined strength and flexibility of Mylar, making it less effective for long-term preservation.

Durability and Tear Resistance Comparison

Mylar wrapping offers superior durability and tear resistance compared to foil wrapping, thanks to its polyester film composition that resists punctures and maintains integrity under stress. Foil wrapping, while flexible and heat conductive, is more prone to tearing and puncturing due to its thin aluminum layer. For applications requiring long-lasting protection and resistance to damage, Mylar provides a more reliable wrapping solution.

Flexibility and Ease of Use

Mylar wrapping offers superior flexibility compared to foil wrapping, making it easier to conform to irregular shapes and tight corners without tearing. Its lightweight material allows for seamless application and better cushioning, enhancing protection during handling and transport. In contrast, foil wrapping tends to be stiffer and more prone to crinkling, reducing ease of use in detailed or delicate packaging tasks.

Aesthetic Appeal and Customization Options

Mylar wrapping offers a sleek, reflective surface that enhances aesthetic appeal with vibrant, high-gloss finishes and vivid color depth, making it ideal for premium packaging and decorative purposes. It allows extensive customization through digital printing, embossing, and metallic effects, enabling unique designs that foil wrapping, which typically provides limited texture and color options, cannot easily achieve. Foil wrapping excels in classic metallic sheen and texture but lacks the versatility and high-resolution printing capabilities that make Mylar wrapping a superior choice for tailored visual impact.

Cost-Effectiveness and Availability

Mylar wrapping offers greater cost-effectiveness than foil wrapping due to its lower material costs and longer durability, making it ideal for bulk packaging and long-term storage. Its wide availability across various industries, including food and electronics, ensures easy procurement compared to the more specialized foil materials. Foil wrapping, while providing superior barrier properties for certain applications, generally incurs higher expenses and limited accessibility in large quantities.

Food Safety and Shelf Life Extension

Mylar wrapping offers superior food safety by providing a durable, moisture-proof, and oxygen-impermeable barrier that significantly extends shelf life compared to traditional foil wrapping. Unlike foil, Mylar is less prone to tearing and punctures, maintaining an airtight seal that prevents contamination and preserves freshness. Its reflective surface also protects against light exposure, further enhancing the longevity of stored food products.

Environmental Impact and Recyclability

Mylar wrapping, made from biaxially-oriented polyethylene terephthalate (BoPET), offers superior environmental benefits over traditional foil wrapping due to its longer lifespan and reusability, reducing overall waste. Unlike aluminum foil, which often ends up in landfills due to limited recycling facilities and contamination issues, Mylar is recyclable in many regions when properly cleaned, aiding in resource conservation. Its lower carbon footprint during production and potential for multiple reuse cycles make Mylar wrapping a more sustainable packaging option in comparison to single-use foil.

Ideal Applications: When to Choose Mylar or Foil

Mylar wrapping is ideal for long-term food storage, moisture protection, and preserving freshness in airtight conditions due to its high barrier properties against oxygen and light. Foil wrapping excels in short-term applications like insulating heat, quick food covering, and convenient reheating, benefiting from its excellent thermal conductivity and malleability. Choosing Mylar is best for vacuum sealing and extended shelf life, while foil suits immediate use and thermal insulation needs.

Mylar Wrapping vs Foil Wrapping Infographic

materialdif.com

materialdif.com