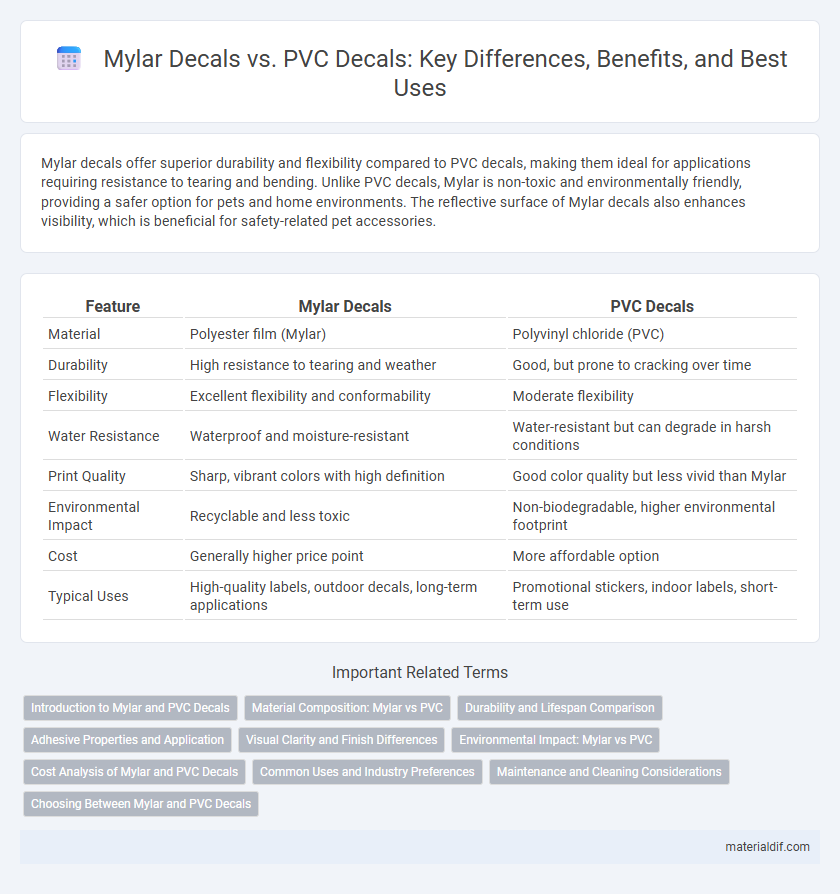

Mylar decals offer superior durability and flexibility compared to PVC decals, making them ideal for applications requiring resistance to tearing and bending. Unlike PVC decals, Mylar is non-toxic and environmentally friendly, providing a safer option for pets and home environments. The reflective surface of Mylar decals also enhances visibility, which is beneficial for safety-related pet accessories.

Table of Comparison

| Feature | Mylar Decals | PVC Decals |

|---|---|---|

| Material | Polyester film (Mylar) | Polyvinyl chloride (PVC) |

| Durability | High resistance to tearing and weather | Good, but prone to cracking over time |

| Flexibility | Excellent flexibility and conformability | Moderate flexibility |

| Water Resistance | Waterproof and moisture-resistant | Water-resistant but can degrade in harsh conditions |

| Print Quality | Sharp, vibrant colors with high definition | Good color quality but less vivid than Mylar |

| Environmental Impact | Recyclable and less toxic | Non-biodegradable, higher environmental footprint |

| Cost | Generally higher price point | More affordable option |

| Typical Uses | High-quality labels, outdoor decals, long-term applications | Promotional stickers, indoor labels, short-term use |

Introduction to Mylar and PVC Decals

Mylar decals are crafted from durable polyester film known for its high tensile strength, excellent dimensional stability, and resistance to moisture and chemicals. PVC decals, made from polyvinyl chloride, offer flexibility and strong adhesion but may lack the longevity and environmental resistance of Mylar. Both materials serve distinct purposes in signage and labeling, with Mylar favored for high-performance applications and PVC suited for cost-effective, versatile uses.

Material Composition: Mylar vs PVC

Mylar decals are made from biaxially-oriented polyethylene terephthalate (BoPET), a polyester film known for its high tensile strength, clarity, and resistance to moisture and chemicals. PVC decals consist of polyvinyl chloride, a plastic polymer that offers flexibility and durability but is prone to environmental degradation and chemical sensitivity. The superior tensile strength and chemical resistance of Mylar make it a preferred material for long-lasting, high-performance decal applications compared to PVC.

Durability and Lifespan Comparison

Mylar decals offer superior durability due to their resistance to moisture, chemicals, and UV exposure, making them ideal for long-term outdoor use. In comparison, PVC decals typically have a shorter lifespan as they degrade faster under harsh environmental conditions and can become brittle over time. The enhanced longevity of Mylar decals ensures better performance and cost-efficiency for applications requiring extended wear.

Adhesive Properties and Application

Mylar decals feature a polyester film that offers superior dimensional stability and resistance to environmental factors compared to PVC decals, making them ideal for long-lasting applications. The adhesive properties of Mylar decals provide strong bonding to smooth surfaces with enhanced durability against UV exposure and moisture. PVC decals often have a more flexible adhesive suited for irregular or curved surfaces but may degrade faster under harsh weather conditions.

Visual Clarity and Finish Differences

Mylar decals offer superior visual clarity due to their smooth, glossy surface, which enhances color vibrancy and sharpness compared to PVC decals. The finish of Mylar is typically shinier and more reflective, providing a high-end appearance that is resistant to fading and yellowing over time. PVC decals often have a matte or semi-gloss finish, which can dull colors and reduce the overall crispness of the graphic.

Environmental Impact: Mylar vs PVC

Mylar decals are more environmentally friendly than PVC decals due to their recyclable polyester composition, which reduces waste and supports sustainability efforts. PVC decals contain harmful chlorine compounds that release toxic dioxins during production and disposal, contributing to environmental pollution. Choosing Mylar minimizes ecological harm and promotes safer, greener decal applications.

Cost Analysis of Mylar and PVC Decals

Mylar decals typically cost more upfront than PVC decals due to the higher quality polyester film used, offering superior durability and resistance to fading. PVC decals are generally less expensive, making them suitable for short-term or budget-conscious projects, but they may require more frequent replacement. The long-term cost efficiency of Mylar decals often offsets the initial investment with prolonged lifespan and reduced maintenance expenses.

Common Uses and Industry Preferences

Mylar decals are commonly used in industries requiring high durability and chemical resistance, such as automotive and aerospace, due to their strong polyester film base. PVC decals are preferred in retail and promotional applications for their flexibility and cost-effectiveness. Industry preferences favor Mylar for outdoor and heavy-use environments, while PVC is chosen for short-term and indoor projects.

Maintenance and Cleaning Considerations

Mylar decals require minimal maintenance due to their durable polyester film composition, which resists moisture, fading, and scratches, making them ideal for long-term outdoor use. In contrast, PVC decals may need more frequent cleaning and protection against harsh weather conditions as their vinyl material can degrade or discolor over time. Proper cleaning for Mylar decals involves gentle wiping with a non-abrasive cloth and mild soap, whereas PVC decals might require specialized cleaners to avoid surface damage and maintain vibrancy.

Choosing Between Mylar and PVC Decals

Mylar decals offer superior durability and flexibility compared to PVC decals, making them ideal for applications requiring long-lasting outdoor performance. PVC decals provide vibrant color options and cost-effectiveness but may degrade faster under UV exposure. Choosing between Mylar and PVC decals depends on the balance between budget constraints and the need for weather resistance and longevity.

Mylar Decals vs PVC Decals Infographic

materialdif.com

materialdif.com