Mylar sheets offer superior durability and clarity compared to acetate sheets, making them ideal for long-term projects and presentations. They provide better resistance to moisture and chemicals, ensuring longevity in various environments. Acetate sheets, while more affordable and flexible, tend to degrade faster and are more susceptible to yellowing over time.

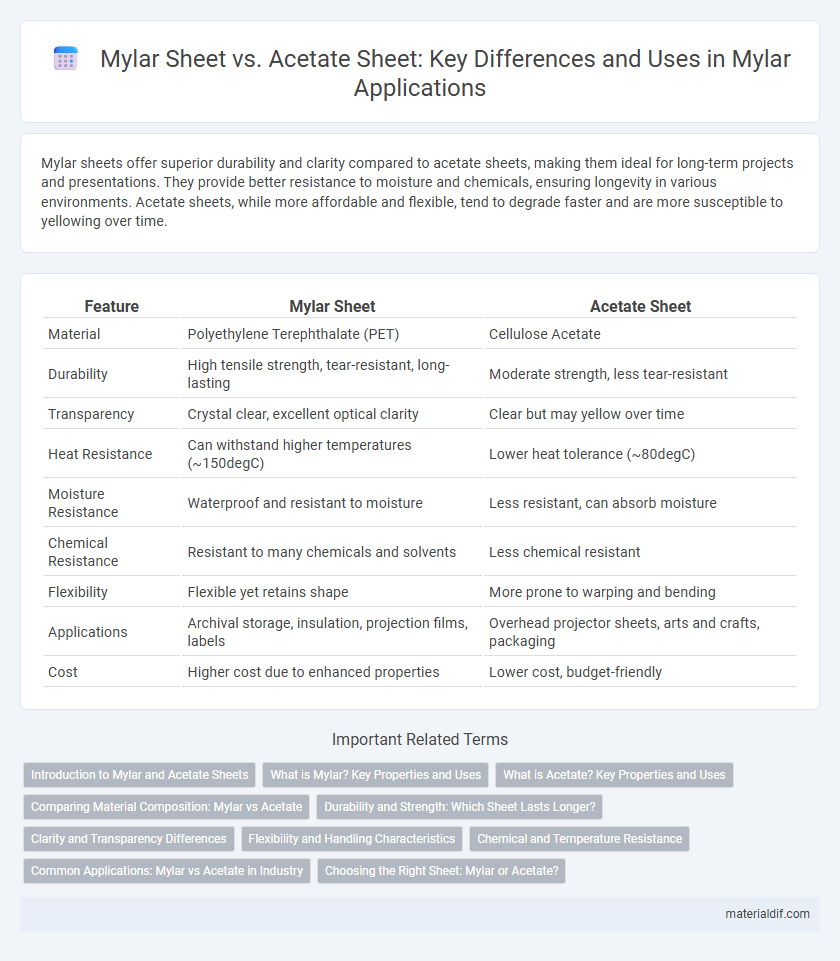

Table of Comparison

| Feature | Mylar Sheet | Acetate Sheet |

|---|---|---|

| Material | Polyethylene Terephthalate (PET) | Cellulose Acetate |

| Durability | High tensile strength, tear-resistant, long-lasting | Moderate strength, less tear-resistant |

| Transparency | Crystal clear, excellent optical clarity | Clear but may yellow over time |

| Heat Resistance | Can withstand higher temperatures (~150degC) | Lower heat tolerance (~80degC) |

| Moisture Resistance | Waterproof and resistant to moisture | Less resistant, can absorb moisture |

| Chemical Resistance | Resistant to many chemicals and solvents | Less chemical resistant |

| Flexibility | Flexible yet retains shape | More prone to warping and bending |

| Applications | Archival storage, insulation, projection films, labels | Overhead projector sheets, arts and crafts, packaging |

| Cost | Higher cost due to enhanced properties | Lower cost, budget-friendly |

Introduction to Mylar and Acetate Sheets

Mylar sheets, made from biaxially-oriented polyethylene terephthalate (BoPET), offer exceptional durability, clarity, and chemical resistance, making them ideal for long-term archival and industrial applications. Acetate sheets, derived from cellulose acetate, provide good transparency and flexibility but are prone to yellowing and degradation over time. The superior dimensional stability and strength of Mylar distinguish it from acetate, especially in environments requiring prolonged exposure to light and humidity.

What is Mylar? Key Properties and Uses

Mylar is a brand name for biaxially-oriented polyethylene terephthalate (BoPET) film known for its exceptional tensile strength, chemical stability, and electrical insulation properties. Unlike acetate sheets, which are prone to shrinking, Mylar sheets maintain dimensional stability and offer superior clarity, making them ideal for archival storage, insulation, and graphic arts applications. Its resistance to moisture, chemicals, and temperature variations extends its utility across multiple industrial and consumer uses.

What is Acetate? Key Properties and Uses

Acetate is a transparent, flexible plastic sheet made from cellulose acetate, known for its excellent clarity, lightweight nature, and ease of printing. Key properties include chemical resistance, dimensional stability, and moderate durability, making it ideal for overhead projector transparencies, packaging, and craft applications. Unlike Mylar, which is made from polyethylene terephthalate (PET), acetate sheets offer better biodegradability but lower tensile strength and heat resistance.

Comparing Material Composition: Mylar vs Acetate

Mylar sheets are made from biaxially-oriented polyethylene terephthalate (BoPET), offering superior tensile strength, chemical stability, and heat resistance compared to acetate sheets, which are derived from cellulose acetate, a plant-based polymer. The synthetic polyester structure of Mylar provides enhanced durability and dimensional stability, while acetate sheets tend to be more prone to warping and are less resistant to moisture and heat. These material differences make Mylar sheets preferable for applications requiring long-term clarity and environmental resilience.

Durability and Strength: Which Sheet Lasts Longer?

Mylar sheets outperform acetate sheets in durability and strength, offering superior resistance to tearing, moisture, and chemicals. Made from biaxially-oriented polyethylene terephthalate (BoPET), Mylar retains shape and clarity over time, making it ideal for long-term applications. Acetate sheets tend to yellow and become brittle with age, resulting in shorter lifespan and reduced reliability.

Clarity and Transparency Differences

Mylar sheets exhibit superior clarity and higher transparency compared to acetate sheets, making them ideal for applications requiring precise image reproduction and minimal light distortion. The polyester composition of Mylar results in a more uniform surface and better resistance to moisture, maintaining clear visibility over time. In contrast, acetate sheets tend to yellow and lose transparency more quickly, leading to reduced optical performance in long-term use.

Flexibility and Handling Characteristics

Mylar sheets exhibit superior flexibility compared to acetate sheets, allowing for easier bending and manipulation without cracking. The polyester composition of Mylar provides enhanced durability and resistance to stretching, making it ideal for applications requiring repeated handling. In contrast, acetate sheets tend to be stiffer and more prone to curling, which can affect their usability in precision projects.

Chemical and Temperature Resistance

Mylar sheets exhibit superior chemical resistance compared to acetate sheets, maintaining integrity when exposed to solvents and acids commonly encountered in industrial applications. Mylar offers a high melting point around 250degC, ensuring dimensional stability under elevated temperatures, while acetate sheets typically degrade at lower temperatures near 190degC. This enhanced thermal and chemical resilience makes Mylar the preferred choice for demanding environments requiring durability and long-lasting performance.

Common Applications: Mylar vs Acetate in Industry

Mylar sheets are widely used in industrial applications requiring high tensile strength, chemical resistance, and dimensional stability, such as electrical insulation, solar panel substrates, and packaging films. Acetate sheets are preferred for applications involving transparency and ease of printing, including overhead projector transparencies, photographic film bases, and decorative displays. Industries select Mylar over acetate when durability and moisture resistance are critical, whereas acetate is chosen for cost-effective, short-term uses needing clarity and flexibility.

Choosing the Right Sheet: Mylar or Acetate?

Mylar sheets offer superior durability, chemical resistance, and dimensional stability compared to acetate sheets, making them ideal for long-term archival and protective applications. Acetate sheets are more flexible and cost-effective, suitable for temporary overlays, lightweight packaging, and projects requiring easier cutting or folding. Choosing between Mylar and acetate depends on the specific needs for strength, clarity, longevity, and budget constraints in your project.

Mylar Sheet vs Acetate Sheet Infographic

materialdif.com

materialdif.com