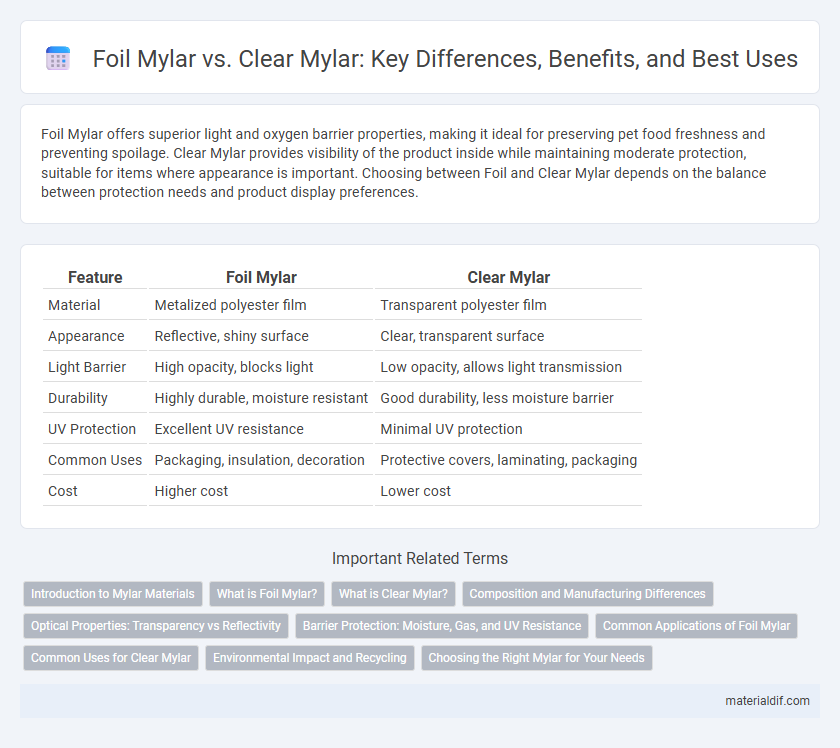

Foil Mylar offers superior light and oxygen barrier properties, making it ideal for preserving pet food freshness and preventing spoilage. Clear Mylar provides visibility of the product inside while maintaining moderate protection, suitable for items where appearance is important. Choosing between Foil and Clear Mylar depends on the balance between protection needs and product display preferences.

Table of Comparison

| Feature | Foil Mylar | Clear Mylar |

|---|---|---|

| Material | Metalized polyester film | Transparent polyester film |

| Appearance | Reflective, shiny surface | Clear, transparent surface |

| Light Barrier | High opacity, blocks light | Low opacity, allows light transmission |

| Durability | Highly durable, moisture resistant | Good durability, less moisture barrier |

| UV Protection | Excellent UV resistance | Minimal UV protection |

| Common Uses | Packaging, insulation, decoration | Protective covers, laminating, packaging |

| Cost | Higher cost | Lower cost |

Introduction to Mylar Materials

Mylar, a polyester film known for its durability and flexibility, comes in various forms including Foil Mylar and Clear Mylar, each serving distinct applications. Foil Mylar features a metallic coating that enhances reflection, heat resistance, and barrier properties, making it ideal for insulation and packaging. Clear Mylar offers transparency, high tensile strength, and excellent electrical insulation, commonly used in protective coverings and graphic arts.

What is Foil Mylar?

Foil Mylar is a metallic polyester film characterized by its reflective, shiny surface, providing superior light and moisture barrier properties compared to Clear Mylar. This type of Mylar is commonly used in packaging, insulation, and decorative applications due to its durability and ability to reflect heat and light efficiently. Unlike Clear Mylar, which is transparent and primarily used for visibility and protection, Foil Mylar offers enhanced opacity and strength, making it ideal for preserving sensitive products.

What is Clear Mylar?

Clear Mylar is a transparent polyester film renowned for its high tensile strength, chemical stability, and excellent electrical insulation properties. Unlike Foil Mylar, which has a metallic coating, Clear Mylar allows light to pass through, making it ideal for applications requiring visibility and protection, such as document sleeves, insulation windows, and art preservation. Its clarity and durability ensure it maintains transparency while providing resistance to moisture, UV light, and temperature variations.

Composition and Manufacturing Differences

Foil Mylar consists of a polyester film coated with a thin layer of metal, typically aluminum, enhancing its reflective properties and durability, while Clear Mylar remains transparent as it lacks any metallic coating. The manufacturing process of Foil Mylar involves vapor deposition of aluminum onto the polyester base under vacuum conditions, resulting in a highly reflective surface, whereas Clear Mylar is produced through biaxial orientation of polyethylene terephthalate (PET) without additional coatings. These differences in composition and manufacturing impart Foil Mylar with improved barrier properties against moisture and light, distinct from the clarity and flexibility offered by Clear Mylar.

Optical Properties: Transparency vs Reflectivity

Foil Mylar exhibits high reflectivity, making it ideal for applications requiring light reflection and insulation, while Clear Mylar offers superior transparency, allowing maximum light transmission for display or packaging purposes. The reflective surface of Foil Mylar effectively bounces light, contributing to energy efficiency and heat retention, whereas Clear Mylar's transparent optical properties ensure visibility and protection without obstructing view. Understanding the trade-off between optical reflectivity and transparency is crucial for selecting the appropriate Mylar variant based on specific project requirements.

Barrier Protection: Moisture, Gas, and UV Resistance

Foil Mylar offers superior barrier protection against moisture, gases, and UV radiation due to its multi-layer metallized structure, making it ideal for preserving sensitive products and extending shelf life. Clear Mylar, while providing good moisture resistance, lacks the enhanced gas and UV barrier properties, allowing more light and oxygen to penetrate. Choosing Foil Mylar is essential for applications requiring maximum environmental protection and product stability.

Common Applications of Foil Mylar

Foil Mylar is widely used in applications requiring high durability and reflective properties, such as emergency blankets, insulation in packaging, and decorative wrapping. Its metallic surface enhances heat retention and light reflection, making it ideal for thermal insulation in automotive and aerospace industries. Foil Mylar also finds use in electronic circuit boards and flexible packaging, where moisture and oxygen barriers are essential.

Common Uses for Clear Mylar

Clear Mylar is widely used in greenhouse applications due to its excellent light transmission properties, allowing optimal sunlight penetration for plant growth. It serves as a protective barrier in packaging, preserving product freshness without obscuring visibility. Additionally, clear Mylar is favored in insulating window films that enhance energy efficiency while maintaining transparency.

Environmental Impact and Recycling

Foil Mylar is metallized and less recyclable due to its multi-layer composition, contributing to greater environmental impact compared to Clear Mylar, which is typically made from polyethylene terephthalate (PET) and is more easily recycled. Clear Mylar's recyclability supports waste reduction and promotes a lower carbon footprint in packaging applications. Utilizing Clear Mylar aligns better with sustainable material sourcing and end-of-life disposal practices, aiding in circular economy efforts.

Choosing the Right Mylar for Your Needs

Foil Mylar provides superior light and moisture barrier properties, making it ideal for packaging sensitive products or insulation purposes. Clear Mylar offers transparency and good strength, suitable for protective covers or lightweight applications where visibility is important. Selecting the right Mylar depends on whether barrier protection or transparency is prioritized for your specific use case.

Foil Mylar vs Clear Mylar Infographic

materialdif.com

materialdif.com