Heat shrink Mylar offers enhanced sealing properties by conforming tightly to the shape of the item, providing superior protection against moisture, dust, and air compared to standard Mylar. Standard Mylar films are durable and resistant to punctures but lack the ability to shrink, making heat shrink Mylar ideal for preserving food freshness and delicate electronics. Choosing heat shrink Mylar ensures a secure, tamper-evident seal that extends shelf life and improves storage efficiency.

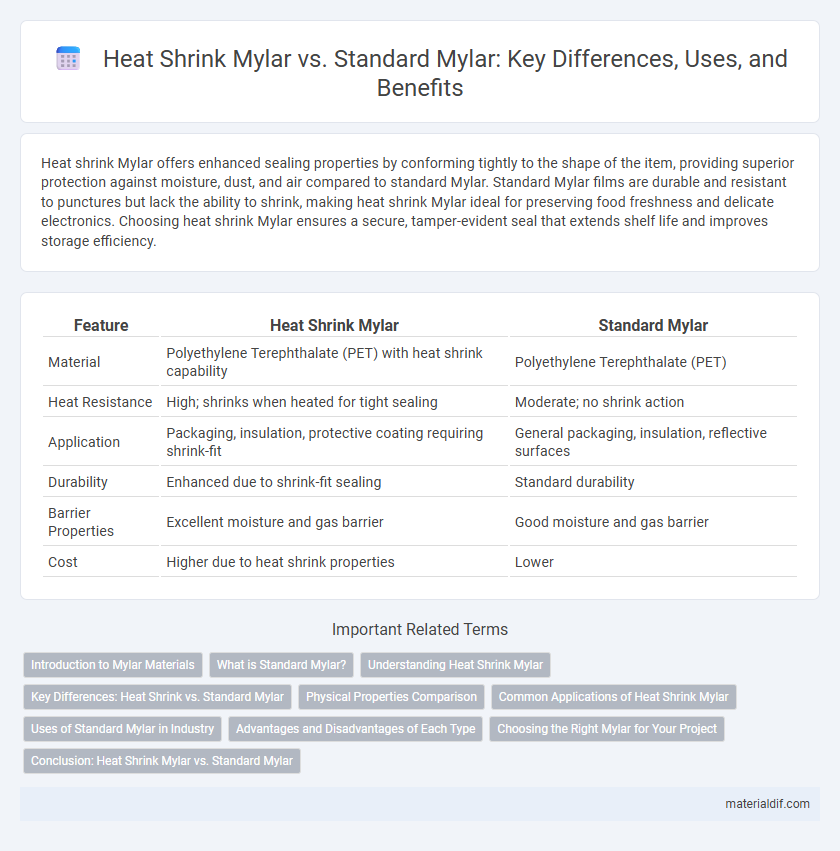

Table of Comparison

| Feature | Heat Shrink Mylar | Standard Mylar |

|---|---|---|

| Material | Polyethylene Terephthalate (PET) with heat shrink capability | Polyethylene Terephthalate (PET) |

| Heat Resistance | High; shrinks when heated for tight sealing | Moderate; no shrink action |

| Application | Packaging, insulation, protective coating requiring shrink-fit | General packaging, insulation, reflective surfaces |

| Durability | Enhanced due to shrink-fit sealing | Standard durability |

| Barrier Properties | Excellent moisture and gas barrier | Good moisture and gas barrier |

| Cost | Higher due to heat shrink properties | Lower |

Introduction to Mylar Materials

Heat Shrink Mylar differs from Standard Mylar by its ability to contract when exposed to heat, allowing for tighter, customized fits in packaging and insulation applications. Standard Mylar, made from biaxially-oriented polyethylene terephthalate (BoPET), offers excellent tensile strength, chemical stability, and barrier properties but does not shrink. Both materials are valued for their durability, moisture resistance, and versatility in electronic, food, and industrial uses.

What is Standard Mylar?

Standard Mylar is a versatile polyester film known for its tensile strength, dimensional stability, and excellent electrical insulation properties. It is commonly used in packaging, insulation, and protective coverings due to its clarity and resistance to moisture and chemicals. Unlike Heat Shrink Mylar, Standard Mylar does not shrink when exposed to heat, making it ideal for applications requiring a stable, durable film.

Understanding Heat Shrink Mylar

Heat shrink Mylar is a type of polyester film that contracts when exposed to heat, providing a tight, protective seal ideal for packaging, insulation, and electronic applications. Unlike standard Mylar, which remains rigid and maintains its shape, heat shrink Mylar offers enhanced durability and flexibility by conforming to the contours of objects it covers. This property makes heat shrink Mylar particularly valuable in situations requiring moisture resistance, abrasion protection, and secure encapsulation.

Key Differences: Heat Shrink vs. Standard Mylar

Heat shrink Mylar differs from standard Mylar primarily in its ability to contract when exposed to heat, providing a tight, form-fitting seal ideal for protective packaging and insulation. Standard Mylar offers durability and chemical resistance but lacks the shrink feature, making it more suitable for static applications like reflective insulation or barrier films. The heat shrink quality adds versatility, enabling customized fits and enhanced protection in various industrial and consumer uses.

Physical Properties Comparison

Heat Shrrink Mylar exhibits enhanced tensile strength and flexibility compared to Standard Mylar, allowing it to conform tightly around objects when heat is applied. Its heat shrinkage ratio typically ranges from 20% to 50%, enabling effective shrink-wrapping and improved sealing capabilities. Standard Mylar, by contrast, maintains dimensional stability with minimal elongation under stress but lacks the thermo-responsive shrink properties of Heat Shrink Mylar.

Common Applications of Heat Shrink Mylar

Heat shrink Mylar is commonly used in electrical insulation, packaging, and protective covering applications due to its ability to tightly conform to objects when heated, providing a secure and durable seal. It is ideal for wrapping wires, cables, and electronic components, ensuring protection against moisture, dust, and abrasion. This material also finds frequent use in automotive and aerospace industries for bundling and insulating harnesses in confined spaces.

Uses of Standard Mylar in Industry

Standard Mylar is widely used in the industry for packaging, insulation, and protective barriers due to its excellent tensile strength, chemical resistance, and electrical insulation properties. It serves as a reliable material in electronics for circuit board insulation and in food packaging to preserve freshness and extend shelf life. The film's dimensional stability and resistance to moisture and solvents make it ideal for applications such as graphic arts, solar panels, and magnetic media.

Advantages and Disadvantages of Each Type

Heat shrink Mylar offers precise conformability and enhanced protection by tightly sealing irregular shapes, making it ideal for sensitive electronics and packaging applications. Standard Mylar provides versatility and cost-effectiveness with its flat, rigid structure, but lacks the ability to shrink and conform, which may lead to less secure sealing. The choice between heat shrink and standard Mylar depends on specific use cases requiring flexibility and tight seals versus general protective covering and affordability.

Choosing the Right Mylar for Your Project

Heat shrink Mylar offers enhanced durability and a tight seal, making it ideal for packaging applications that require moisture protection and tamper resistance. Standard Mylar provides excellent clarity and strength, suitable for general use such as insulation, labeling, or decorative purposes. Selecting the right Mylar depends on project requirements for flexibility, environmental resistance, and dimensional stability under varying temperatures.

Conclusion: Heat Shrink Mylar vs. Standard Mylar

Heat Shrink Mylar offers superior conformity and airtight sealing compared to Standard Mylar, making it ideal for packaging sensitive electronics and food products. It provides enhanced durability and resistance to environmental factors, ensuring prolonged protection and preservation. Standard Mylar remains a cost-effective choice for general applications where flexibility and heat-shrink properties are not critical.

Heat Shrink Mylar vs Standard Mylar Infographic

materialdif.com

materialdif.com