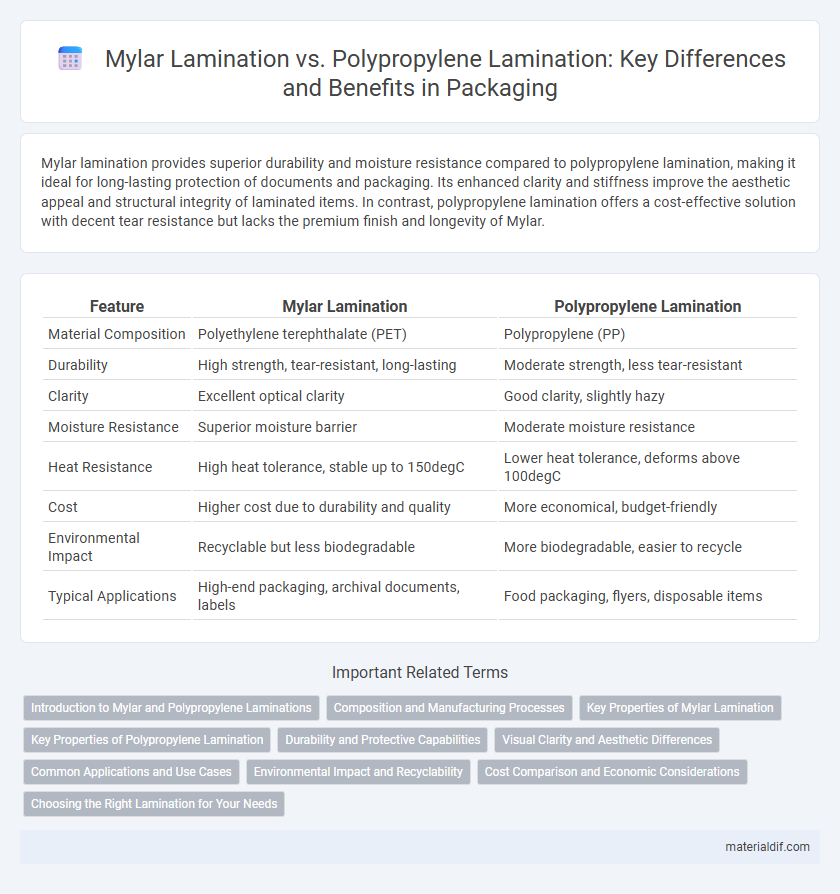

Mylar lamination provides superior durability and moisture resistance compared to polypropylene lamination, making it ideal for long-lasting protection of documents and packaging. Its enhanced clarity and stiffness improve the aesthetic appeal and structural integrity of laminated items. In contrast, polypropylene lamination offers a cost-effective solution with decent tear resistance but lacks the premium finish and longevity of Mylar.

Table of Comparison

| Feature | Mylar Lamination | Polypropylene Lamination |

|---|---|---|

| Material Composition | Polyethylene terephthalate (PET) | Polypropylene (PP) |

| Durability | High strength, tear-resistant, long-lasting | Moderate strength, less tear-resistant |

| Clarity | Excellent optical clarity | Good clarity, slightly hazy |

| Moisture Resistance | Superior moisture barrier | Moderate moisture resistance |

| Heat Resistance | High heat tolerance, stable up to 150degC | Lower heat tolerance, deforms above 100degC |

| Cost | Higher cost due to durability and quality | More economical, budget-friendly |

| Environmental Impact | Recyclable but less biodegradable | More biodegradable, easier to recycle |

| Typical Applications | High-end packaging, archival documents, labels | Food packaging, flyers, disposable items |

Introduction to Mylar and Polypropylene Laminations

Mylar lamination uses a polyester film known for its durability, clarity, and excellent moisture and chemical resistance, making it ideal for long-lasting applications. Polypropylene lamination utilizes a thermoplastic polymer film that offers flexibility, lower cost, and decent barrier properties, commonly used for packaging and printing purposes. Both Mylar and polypropylene laminations enhance product protection, but Mylar provides superior strength and temperature resistance compared to polypropylene.

Composition and Manufacturing Processes

Mylar lamination utilizes biaxially-oriented polyethylene terephthalate (BoPET), known for its high tensile strength and clarity, produced through melt extrusion and biaxial stretching. Polypropylene lamination involves polypropylene film, created via polymerization and film casting or blown film processes, offering flexibility and moisture resistance. The manufacturing of Mylar includes biaxial orientation which enhances dimensional stability, while polypropylene lamination emphasizes cost-effectiveness and chemical resistance due to its simpler production method.

Key Properties of Mylar Lamination

Mylar lamination offers superior tensile strength and dimensional stability compared to polypropylene lamination, making it ideal for applications requiring durability and resistance to tearing. It provides excellent heat resistance and barrier properties against moisture, gases, and chemicals, ensuring long-lasting protection for printed materials. The clarity and gloss of Mylar laminated surfaces enhance visual appeal, while its resistance to UV light prevents fading over time.

Key Properties of Polypropylene Lamination

Polypropylene lamination offers excellent moisture resistance, making it ideal for packaging applications requiring durability and protection against humidity. It provides a high clarity finish with a smooth surface, enhancing product visibility and print quality. This type of lamination is also cost-effective and recyclable, supporting sustainable packaging solutions.

Durability and Protective Capabilities

Mylar lamination offers superior durability with its high tensile strength and resistance to moisture, chemicals, and temperature variations, making it ideal for long-lasting protection. Polypropylene lamination provides good clarity and resistance to tearing but lacks the same level of moisture barrier and chemical resistance as Mylar. The enhanced protective capabilities of Mylar make it the preferred choice for preserving valuable documents and packaging sensitive materials.

Visual Clarity and Aesthetic Differences

Mylar lamination offers superior visual clarity compared to polypropylene lamination due to its higher gloss and transparency, enhancing the vibrancy of printed colors and sharpness of images. The smooth, reflective surface of Mylar provides a premium aesthetic appeal, making it ideal for high-end packaging and presentation materials. In contrast, polypropylene lamination tends to have a slightly matte finish, resulting in less brilliance but offering a more subtle and durable look.

Common Applications and Use Cases

Mylar lamination is widely used for high-durability applications such as ID cards, food packaging, and medical device covers due to its excellent moisture resistance and tensile strength. Polypropylene lamination dominates in cost-sensitive packaging like snack bags, labels, and book covers because of its flexibility and lower environmental impact. Both materials serve diverse industries, with Mylar preferred for prolonged protection and Polypropylene favored for lightweight, recyclable solutions.

Environmental Impact and Recyclability

Mylar lamination, made from biaxially-oriented polyethylene terephthalate (BoPET), offers superior durability but presents recycling challenges due to its polyester base and energy-intensive production. Polypropylene lamination, derived from polyolefin, is more environmentally friendly with lower carbon emissions and easier recyclability in standard plastic waste streams. Selecting polypropylene lamination reduces ecological footprint, supporting circular economy goals through better compatibility with existing recycling infrastructure.

Cost Comparison and Economic Considerations

Mylar lamination typically costs more than polypropylene lamination due to higher raw material and production expenses, but it offers superior durability and chemical resistance, which can reduce long-term replacement costs. Polypropylene lamination provides a more economical option upfront, favored for short-term projects or budget-conscious applications where moisture resistance is moderate. Evaluating total lifecycle costs, including longevity and performance under environmental stress, is critical for businesses deciding between these two lamination materials.

Choosing the Right Lamination for Your Needs

Mylar lamination offers superior clarity, durability, and heat resistance, making it ideal for high-quality prints and long-lasting protection. Polypropylene lamination is cost-effective and provides good moisture resistance, suitable for short-term applications or budget-conscious projects. Selecting the right lamination depends on the desired durability, environmental exposure, and budget constraints of your specific project.

Mylar Lamination vs Polypropylene Lamination Infographic

materialdif.com

materialdif.com