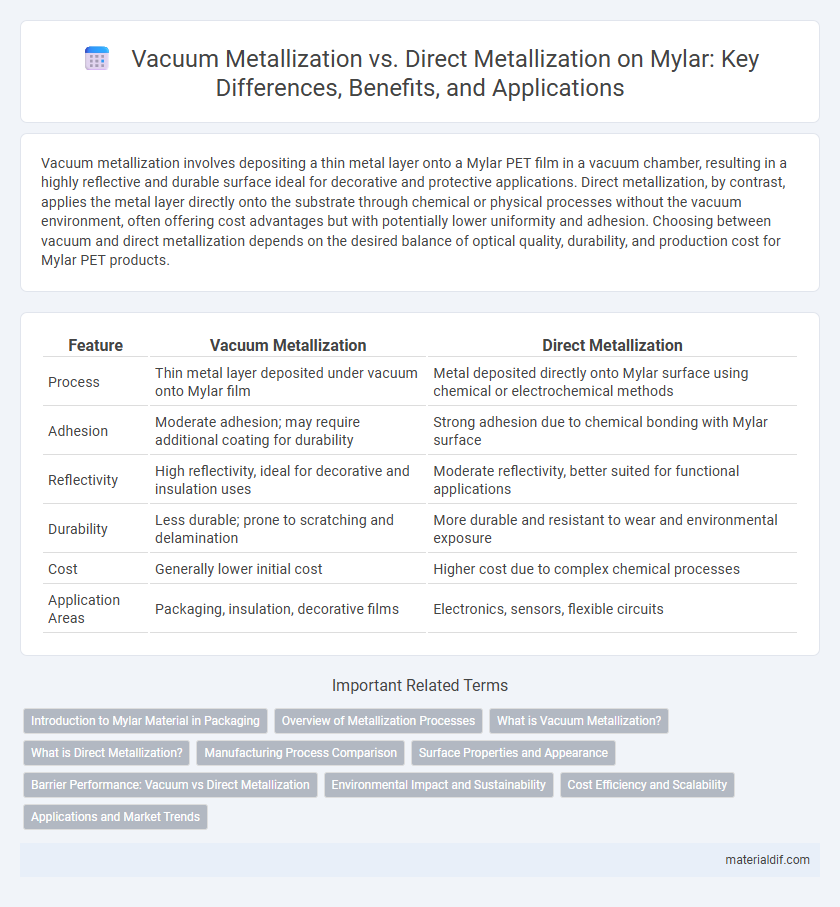

Vacuum metallization involves depositing a thin metal layer onto a Mylar PET film in a vacuum chamber, resulting in a highly reflective and durable surface ideal for decorative and protective applications. Direct metallization, by contrast, applies the metal layer directly onto the substrate through chemical or physical processes without the vacuum environment, often offering cost advantages but with potentially lower uniformity and adhesion. Choosing between vacuum and direct metallization depends on the desired balance of optical quality, durability, and production cost for Mylar PET products.

Table of Comparison

| Feature | Vacuum Metallization | Direct Metallization |

|---|---|---|

| Process | Thin metal layer deposited under vacuum onto Mylar film | Metal deposited directly onto Mylar surface using chemical or electrochemical methods |

| Adhesion | Moderate adhesion; may require additional coating for durability | Strong adhesion due to chemical bonding with Mylar surface |

| Reflectivity | High reflectivity, ideal for decorative and insulation uses | Moderate reflectivity, better suited for functional applications |

| Durability | Less durable; prone to scratching and delamination | More durable and resistant to wear and environmental exposure |

| Cost | Generally lower initial cost | Higher cost due to complex chemical processes |

| Application Areas | Packaging, insulation, decorative films | Electronics, sensors, flexible circuits |

Introduction to Mylar Material in Packaging

Mylar, a biaxially oriented polyethylene terephthalate (BoPET) film, is widely used in packaging due to its excellent barrier properties and mechanical strength. Vacuum metallization deposits a thin layer of metal, typically aluminum, onto the Mylar surface in a vacuum chamber, enhancing reflectivity and moisture resistance. In contrast, direct metallization chemically applies metal onto Mylar, offering improved adhesion and durability for specialized packaging applications.

Overview of Metallization Processes

Vacuum metallization involves depositing a thin metal layer onto Mylar by vaporizing metal in a high-vacuum chamber, creating a reflective and durable surface. Direct metallization applies metal particles directly onto Mylar through chemical or physical processes, offering enhanced adhesion and conductivity. Both processes improve Mylar's barrier properties, optical clarity, and electrical performance for packaging, insulation, and electronic applications.

What is Vacuum Metallization?

Vacuum metallization is a process where a thin layer of metal, typically aluminum, is deposited onto Mylar film in a vacuum chamber to create a reflective and barrier coating. This technique enhances the film's optical properties and moisture resistance by uniformly applying metal without the use of adhesives. Vacuum metallized Mylar is widely used in packaging, insulation, and decorative applications due to its lightweight and highly reflective surface.

What is Direct Metallization?

Direct metallization is a process where a thin metal layer, often aluminum or copper, is directly deposited onto the Mylar film surface without the need for a separate vacuum chamber or substrate. This method enhances adhesion, improves barrier properties, and maintains film flexibility, making it ideal for packaging and decorative applications. Direct metallization offers precise control over coating thickness and uniformity, resulting in high-quality reflective or conductive surfaces on Mylar.

Manufacturing Process Comparison

Vacuum metallization involves depositing a thin metal layer onto Mylar films within a vacuum chamber, ensuring uniform coating and enhanced barrier properties. Direct metallization applies metal layers through chemical or sputtering techniques directly on Mylar surfaces, offering better adhesion and flexibility in patterning. The vacuum process excels in consistency and reflectivity, while direct metallization provides cost-effective production and improved environmental resistance.

Surface Properties and Appearance

Vacuum metallization on Mylar provides a highly reflective, uniform surface with excellent adhesion, resulting in a smooth and mirror-like finish ideal for optical applications. Direct metallization tends to produce a less uniform coating with potential surface irregularities, affecting gloss and reflectivity. The choice between vacuum and direct metallization impacts the Mylar's surface energy, durability, and final appearance significantly.

Barrier Performance: Vacuum vs Direct Metallization

Vacuum metallization on Mylar provides superior barrier performance by creating a uniform, dense metal layer that effectively blocks moisture and gases, enhancing product protection and shelf life. Direct metallization often results in a thinner, less consistent coating, leading to lower barrier properties and increased permeability. The choice between vacuum and direct metallization directly impacts the Mylar film's durability and efficiency in applications requiring high moisture and oxygen resistance.

Environmental Impact and Sustainability

Vacuum metallization on Mylar films consumes significant energy due to high-vacuum equipment and metal vaporization processes, resulting in a larger carbon footprint compared to direct metallization, which applies thin metal layers through chemical or sputtering methods with lower emissions. Direct metallization reduces environmental impact by minimizing hazardous waste and improving recyclability of Mylar products, enhancing overall sustainability. Choosing direct metallization supports eco-friendly manufacturing, aligning with industry goals to decrease volatile organic compounds and resource consumption in Mylar film production.

Cost Efficiency and Scalability

Vacuum metallization of Mylar offers higher cost efficiency in large-scale production due to automated batch processing and minimal material waste, making it ideal for high-volume packaging industries. Direct metallization, while providing superior adhesion and finer patterning for specialized applications, tends to incur higher costs and limited scalability because of slower processing speeds and more complex equipment requirements. Choosing vacuum metallization enables economies of scale and predictable cost per unit, whereas direct metallization suits customized orders where performance justifies greater investment.

Applications and Market Trends

Vacuum metallization of Mylar films is predominantly utilized in packaging, automotive, and decorative applications due to its ability to produce uniform, high-reflectivity coatings ideal for barrier properties and aesthetics. Direct metallization, often involving sputtering or chemical deposition on Mylar, is favored in electronics and solar industries for precise, thin conductive layers essential for flexible circuit boards and photovoltaic cells. Market trends indicate growing demand for vacuum metallized Mylar in sustainable packaging, while direct metallization expands with advancements in flexible electronics and wearable technology sectors.

Vacuum Metallization vs Direct Metallization Infographic

materialdif.com

materialdif.com