Mylar barriers provide excellent moisture and oxygen resistance, making them ideal for extending the shelf life of pet food and treats by maintaining freshness and preventing spoilage. EVOH barriers offer superior oxygen permeability protection, enhancing product preservation by effectively blocking oxygen transmission while allowing for the integration of flexible packaging designs. Choosing between Mylar and EVOH barriers depends on specific packaging needs, with Mylar excelling in moisture resistance and EVOH delivering unmatched oxygen barrier performance.

Table of Comparison

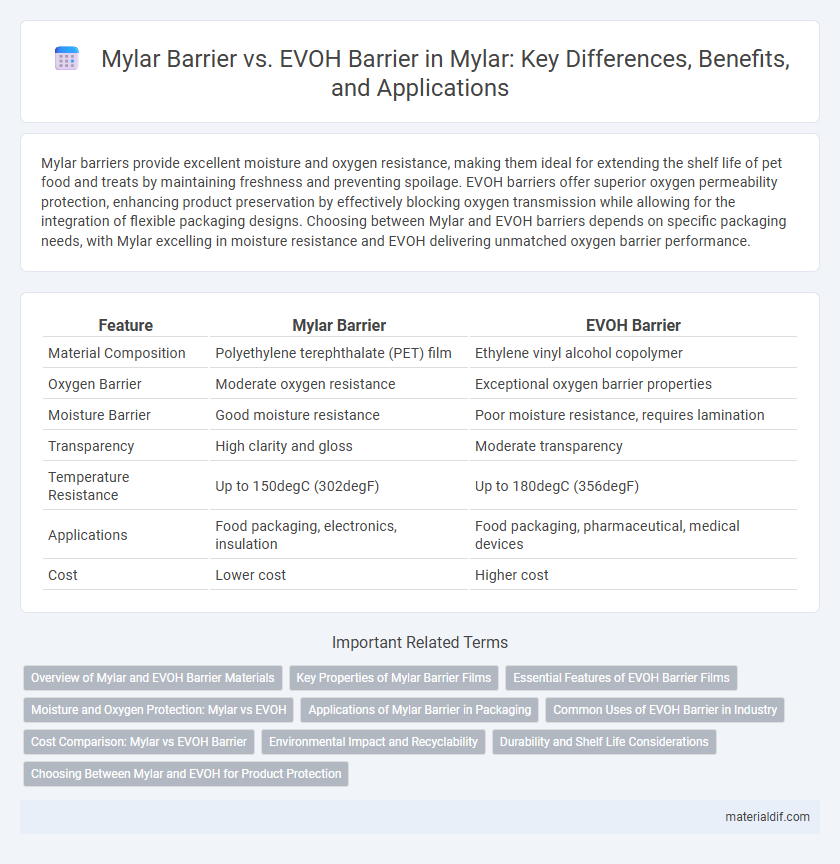

| Feature | Mylar Barrier | EVOH Barrier |

|---|---|---|

| Material Composition | Polyethylene terephthalate (PET) film | Ethylene vinyl alcohol copolymer |

| Oxygen Barrier | Moderate oxygen resistance | Exceptional oxygen barrier properties |

| Moisture Barrier | Good moisture resistance | Poor moisture resistance, requires lamination |

| Transparency | High clarity and gloss | Moderate transparency |

| Temperature Resistance | Up to 150degC (302degF) | Up to 180degC (356degF) |

| Applications | Food packaging, electronics, insulation | Food packaging, pharmaceutical, medical devices |

| Cost | Lower cost | Higher cost |

Overview of Mylar and EVOH Barrier Materials

Mylar, a biaxially-oriented polyethylene terephthalate (BoPET), offers excellent tensile strength, chemical stability, and moisture resistance, making it ideal for packaging and insulation applications. EVOH (ethylene vinyl alcohol) is known for its superior gas barrier properties, especially against oxygen, outperforming Mylar in preserving product freshness by limiting gas permeability. Combining Mylar and EVOH layers enhances barrier performance, providing strength, transparency, and specialized protection essential in food packaging and industrial uses.

Key Properties of Mylar Barrier Films

Mylar barrier films are renowned for their exceptional tensile strength, dimensional stability, and excellent moisture and oxygen resistance, making them ideal for packaging applications requiring long shelf life. Compared to EVOH, Mylar provides superior clarity and better resistance to UV radiation while maintaining a cost-effective profile. Its compatibility with multiple lamination processes enhances its versatility in creating high-performance barrier layers.

Essential Features of EVOH Barrier Films

EVOH barrier films offer superior gas and moisture resistance compared to Mylar, making them essential for extending product shelf life in food packaging and pharmaceuticals. Their exceptional oxygen barrier properties result from ethylene-vinyl alcohol copolymer composition, which significantly reduces oxygen permeability. Unlike Mylar, EVOH films maintain barrier performance under varying humidity conditions, ensuring consistent protection.

Moisture and Oxygen Protection: Mylar vs EVOH

Mylar films provide excellent moisture barrier properties, making them ideal for protecting products sensitive to humidity, while EVOH films offer superior oxygen barrier performance, crucial for preserving freshness and preventing oxidation. Combining Mylar with EVOH layers creates advanced packaging solutions that effectively block both moisture and oxygen. This synergy enhances shelf life significantly in food, pharmaceuticals, and electronics applications.

Applications of Mylar Barrier in Packaging

Mylar barrier films offer excellent moisture, oxygen, and aroma resistance, making them ideal for food packaging, pharmaceuticals, and electronics protection. Compared to EVOH barriers, Mylar provides superior tensile strength and flexibility, enhancing durability in packaging applications such as snack bags, medical pouches, and consumer electronics wrapping. Their heat-sealable properties also enable efficient processing in automated packaging lines, ensuring product freshness and extended shelf life.

Common Uses of EVOH Barrier in Industry

EVOH barrier films are extensively used in the food packaging industry to provide superior oxygen and aroma barrier properties, thereby extending the shelf life of perishable products such as meats, dairy, and snacks. Pharmaceuticals benefit from EVOH's excellent gas barrier qualities, ensuring the protection of sensitive ingredients from moisture and contaminants. In automotive and fuel packaging, EVOH's chemical resistance and barrier performance safeguard against fuel and oil vapor permeation, enhancing safety and durability.

Cost Comparison: Mylar vs EVOH Barrier

Mylar barriers generally offer a more cost-effective solution compared to EVOH barriers due to lower raw material and manufacturing expenses. EVOH barriers, while providing superior gas and moisture resistance, tend to have higher production costs that can impact overall packaging budgets. Choosing between Mylar and EVOH depends heavily on balancing material performance against budget constraints in packaging applications.

Environmental Impact and Recyclability

Mylar barrier films, known for their excellent strength and clarity, offer good recyclability due to their polyester base, which is widely accepted in recycling streams, reducing environmental impact. EVOH barriers provide superior oxygen resistance but are less recyclable because their copolymer structure complicates separation and processing in standard recycling facilities. Choosing Mylar over EVOH can enhance sustainability efforts by supporting circular economy goals through easier material recovery and lower environmental footprint.

Durability and Shelf Life Considerations

Mylar barriers exhibit exceptional durability due to their high tensile strength and resistance to moisture, making them ideal for long-term packaging solutions. EVOH barriers provide superior oxygen resistance but tend to be more susceptible to moisture degradation, potentially reducing shelf life in high-humidity environments. Selecting Mylar or EVOH depends on balancing durability needs with desired oxygen barrier performance to optimize product preservation.

Choosing Between Mylar and EVOH for Product Protection

Mylar barrier films offer excellent moisture resistance and high tensile strength, making them ideal for packaging products sensitive to humidity. EVOH barriers provide superior oxygen resistance, effectively preserving the freshness and shelf life of food and pharmaceuticals. Choosing between Mylar and EVOH depends on the specific protection needs, with Mylar suited for moisture control and EVOH preferred for oxygen-sensitive applications.

Mylar Barrier vs EVOH Barrier Infographic

materialdif.com

materialdif.com