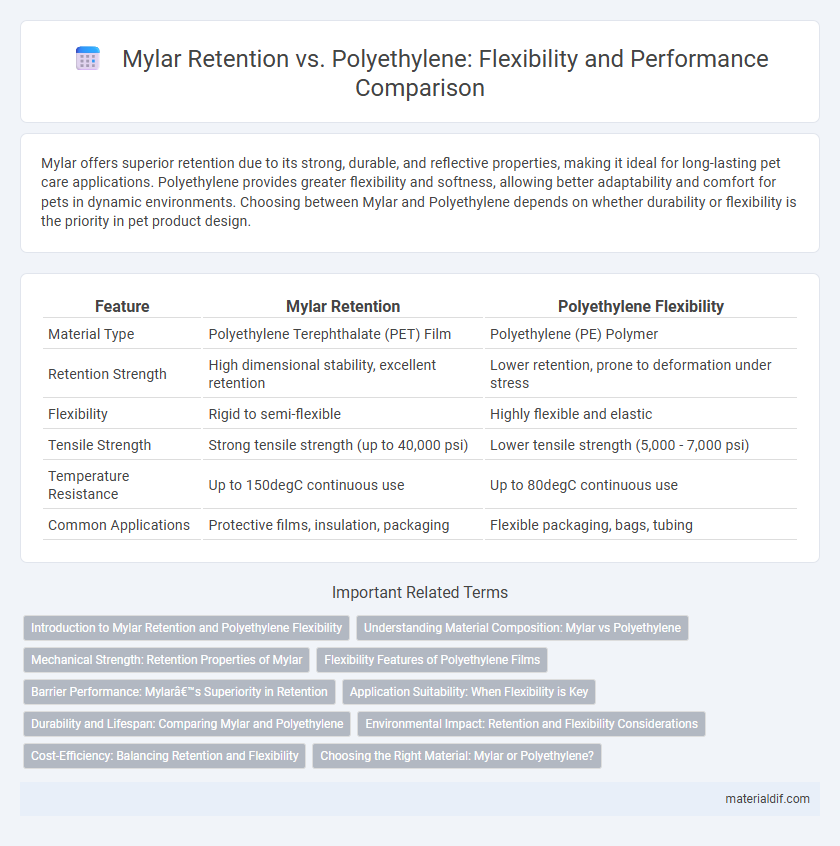

Mylar offers superior retention due to its strong, durable, and reflective properties, making it ideal for long-lasting pet care applications. Polyethylene provides greater flexibility and softness, allowing better adaptability and comfort for pets in dynamic environments. Choosing between Mylar and Polyethylene depends on whether durability or flexibility is the priority in pet product design.

Table of Comparison

| Feature | Mylar Retention | Polyethylene Flexibility |

|---|---|---|

| Material Type | Polyethylene Terephthalate (PET) Film | Polyethylene (PE) Polymer |

| Retention Strength | High dimensional stability, excellent retention | Lower retention, prone to deformation under stress |

| Flexibility | Rigid to semi-flexible | Highly flexible and elastic |

| Tensile Strength | Strong tensile strength (up to 40,000 psi) | Lower tensile strength (5,000 - 7,000 psi) |

| Temperature Resistance | Up to 150degC continuous use | Up to 80degC continuous use |

| Common Applications | Protective films, insulation, packaging | Flexible packaging, bags, tubing |

Introduction to Mylar Retention and Polyethylene Flexibility

Mylar retention refers to the material's exceptional ability to maintain structural integrity and resist deformation under stress, making it ideal for applications requiring durability and dimensional stability. Polyethylene flexibility highlights its superior pliability and impact resistance, allowing it to bend and stretch without breaking, which suits uses demanding high flexibility. Understanding the contrasting properties of Mylar's retention and polyethylene's flexibility is crucial for selecting the right polymer in packaging, insulation, and protective film industries.

Understanding Material Composition: Mylar vs Polyethylene

Mylar, a biaxially-oriented polyethylene terephthalate (BoPET), exhibits superior retention properties due to its crystalline structure and high tensile strength, making it ideal for applications requiring dimensional stability. Polyethylene, a polymer composed of long hydrocarbon chains, offers greater flexibility and elasticity but lacks the rigidity found in Mylar, limiting its use in precise retention contexts. Understanding these material compositions highlights Mylar's advantage in durability and shape retention versus polyethylene's adaptability and stretchability.

Mechanical Strength: Retention Properties of Mylar

Mylar exhibits superior mechanical strength and retention properties compared to polyethylene, maintaining dimensional stability under stress and temperature variations. Its biaxially-oriented polyester film structure enhances tensile strength and resistance to stretching or deformation. This makes Mylar an ideal choice for applications requiring durable, long-lasting retention performance in packaging, insulation, and protective barriers.

Flexibility Features of Polyethylene Films

Polyethylene films exhibit superior flexibility compared to Mylar due to their inherent molecular structure, which allows for greater elongation and bending without cracking. This flexibility makes polyethylene ideal for applications requiring conformability and impact resistance, such as packaging films and protective covers. Unlike Mylar, polyethylene films can endure repeated flexing and stretching while maintaining their integrity and performance.

Barrier Performance: Mylar’s Superiority in Retention

Mylar exhibits exceptional barrier performance, significantly surpassing polyethylene in retaining gases, moisture, and aromas due to its dense, multilayer polyester film structure. This superior retention capability makes Mylar ideal for applications requiring long-term preservation and minimal permeability, such as food packaging and protective coatings. Polyethylene's flexibility comes with higher permeability, resulting in less effective barrier properties compared to Mylar's robust retention advantages.

Application Suitability: When Flexibility is Key

Mylar offers superior dimensional stability and strength, making it ideal for applications requiring firm structure and precise form retention. Polyethylene excels in flexibility and elongation, fitting well in scenarios demanding bendability and resilience under stress. For applications prioritizing flexibility such as flexible packaging or wearable electronics, polyethylene provides better performance compared to the rigid nature of Mylar.

Durability and Lifespan: Comparing Mylar and Polyethylene

Mylar exhibits superior durability and a longer lifespan compared to polyethylene due to its enhanced tensile strength and resistance to moisture, UV light, and chemicals. Polyethylene, while more flexible and less prone to cracking under stress, generally has a shorter lifespan and is more susceptible to environmental degradation. These factors make Mylar the preferred choice for applications requiring long-term protection and stability.

Environmental Impact: Retention and Flexibility Considerations

Mylar demonstrates superior retention capabilities due to its strong barrier properties against moisture, gases, and UV light, significantly extending product shelf life and reducing waste. Polyethylene offers enhanced flexibility, allowing for more adaptable packaging designs but with higher permeability that may lead to shorter preservation periods. From an environmental impact perspective, Mylar's durability supports fewer replacements and less material usage over time, while polyethylene's recyclability and lower production energy contribute to reduced ecological footprints when managed properly.

Cost-Efficiency: Balancing Retention and Flexibility

Mylar offers superior retention properties with high tensile strength and excellent dimensional stability, making it ideal for applications requiring durability and long-term performance. Polyethylene provides greater flexibility and impact resistance at a lower material cost, allowing for versatile uses where bending and stretching are necessary. Balancing cost-efficiency involves selecting Mylar for critical retention needs and polyethylene when enhanced flexibility and budget constraints dictate.

Choosing the Right Material: Mylar or Polyethylene?

Mylar offers superior retention properties due to its high tensile strength and dimensional stability, making it ideal for applications requiring durability and long-term preservation. Polyethylene provides greater flexibility and impact resistance, suitable for packaging and products needing adaptability and resilience. Selecting between Mylar and polyethylene depends on whether retention and rigidity or flexibility and cost-effectiveness are the primary material requirements.

Mylar Retention vs Polyethylene Flexibility Infographic

materialdif.com

materialdif.com