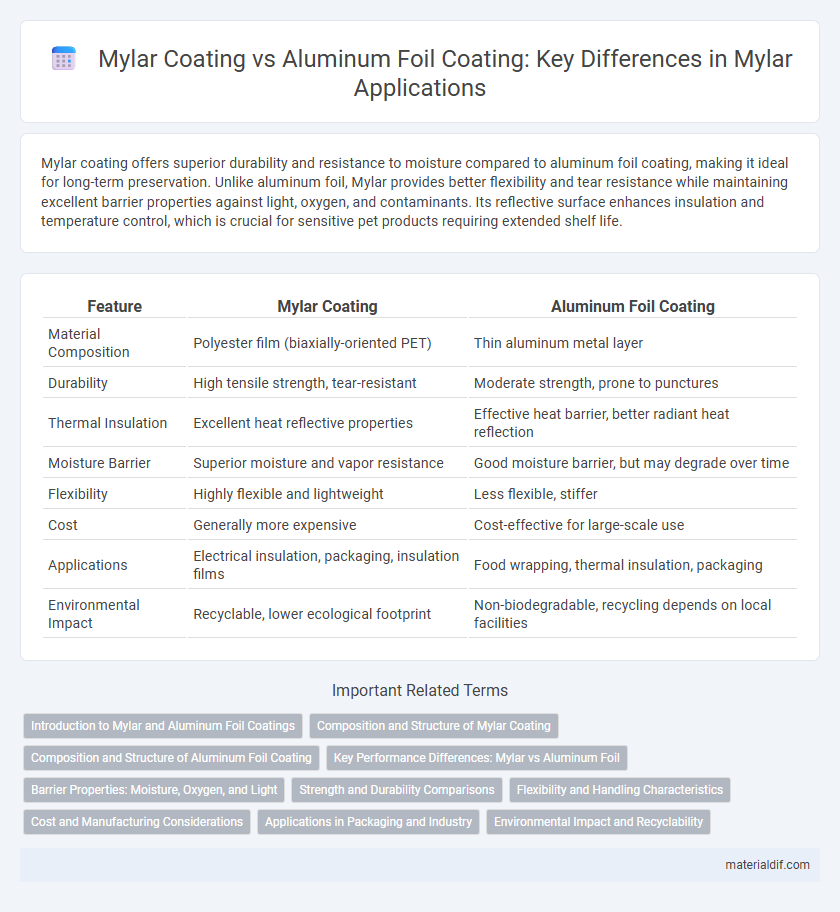

Mylar coating offers superior durability and resistance to moisture compared to aluminum foil coating, making it ideal for long-term preservation. Unlike aluminum foil, Mylar provides better flexibility and tear resistance while maintaining excellent barrier properties against light, oxygen, and contaminants. Its reflective surface enhances insulation and temperature control, which is crucial for sensitive pet products requiring extended shelf life.

Table of Comparison

| Feature | Mylar Coating | Aluminum Foil Coating |

|---|---|---|

| Material Composition | Polyester film (biaxially-oriented PET) | Thin aluminum metal layer |

| Durability | High tensile strength, tear-resistant | Moderate strength, prone to punctures |

| Thermal Insulation | Excellent heat reflective properties | Effective heat barrier, better radiant heat reflection |

| Moisture Barrier | Superior moisture and vapor resistance | Good moisture barrier, but may degrade over time |

| Flexibility | Highly flexible and lightweight | Less flexible, stiffer |

| Cost | Generally more expensive | Cost-effective for large-scale use |

| Applications | Electrical insulation, packaging, insulation films | Food wrapping, thermal insulation, packaging |

| Environmental Impact | Recyclable, lower ecological footprint | Non-biodegradable, recycling depends on local facilities |

Introduction to Mylar and Aluminum Foil Coatings

Mylar coating, a polyester film known for its high tensile strength, chemical stability, and excellent reflective properties, is widely used in insulation, packaging, and electronics industries. Aluminum foil coating provides superior heat resistance and moisture barrier capabilities, making it ideal for thermal insulation and food packaging applications. Both materials serve distinct functions in protective and reflective coatings, with Mylar offering durability and flexibility, while aluminum foil excels in thermal and barrier performance.

Composition and Structure of Mylar Coating

Mylar coating consists of stretched polyethylene terephthalate (PET) film providing high tensile strength, chemical stability, and excellent barrier properties against moisture and gases. Unlike aluminum foil coating, which uses a thin metal layer to reflect heat and light, Mylar's polymer structure offers better flexibility, tear resistance, and dielectric insulation. This composition makes Mylar coatings ideal for applications requiring durability, transparency, and thermal insulation without the brittleness of metal coatings.

Composition and Structure of Aluminum Foil Coating

Mylar coating consists of stretched polyester film known for its high tensile strength and clarity, whereas aluminum foil coating is composed of thin aluminum layers laminated onto substrates. The aluminum foil coating features a multilayer structure with a base metal layer that provides excellent barrier properties against moisture, light, and gases. This composition enhances the foil's reflective and conductive capabilities, making it ideal for insulation and packaging applications.

Key Performance Differences: Mylar vs Aluminum Foil

Mylar coating offers superior tensile strength and better resistance to moisture and chemicals compared to aluminum foil coating, making it ideal for long-term durability in packaging. Aluminum foil excels in barrier properties against light, oxygen, and aroma, providing excellent preservation for sensitive products. While Mylar is flexible and lightweight, aluminum foil provides better thermal conductivity and heat shielding in industrial applications.

Barrier Properties: Moisture, Oxygen, and Light

Mylar coating offers superior barrier properties against moisture, oxygen, and light compared to aluminum foil coating, ensuring enhanced product preservation and longer shelf life. Its polyester-based structure provides excellent resistance to water vapor transmission and oxygen permeability, which is critical for sensitive goods like pharmaceuticals and food products. While aluminum foil excels in light and oxygen blockage, Mylar's combination of flexibility and moisture barrier efficiency makes it a preferred choice for packaging applications requiring transparency and durability.

Strength and Durability Comparisons

Mylar coating offers superior tensile strength and puncture resistance compared to aluminum foil coating, making it more durable for long-term applications. The multi-layer polyester substrate in Mylar provides enhanced flexibility and dimensional stability under temperature fluctuations, unlike aluminum foil which is more prone to tearing and corrosion. Industries requiring moisture barrier protection and high durability prefer Mylar coatings for their resilience and extended lifespan.

Flexibility and Handling Characteristics

Mylar coating offers superior flexibility and durability compared to aluminum foil coating, making it ideal for applications requiring repeated bending or manipulation. Its polymer-based structure resists cracking and maintains integrity under stress, whereas aluminum foil is prone to cracking and fatigue with frequent handling. These handling characteristics make Mylar coatings preferable in flexible packaging, insulation, and electronics where ease of use and longevity are critical.

Cost and Manufacturing Considerations

Mylar coating offers a cost-effective alternative to aluminum foil coating due to lower raw material and production expenses, making it suitable for large-scale manufacturing. The manufacturing process of Mylar is simpler and more energy-efficient, resulting in shorter production cycles and reduced labor costs compared to the complex lamination required for aluminum foil. Mylar's consistent thickness and flexibility contribute to less waste during production, further optimizing overall manufacturing costs.

Applications in Packaging and Industry

Mylar coating offers superior moisture barrier properties and chemical resistance compared to aluminum foil coating, making it ideal for high-performance packaging applications such as food and pharmaceutical products. Aluminum foil coating excels in heat reflection and provides a strong metallic barrier, commonly used in insulation materials and industrial packaging where temperature control is critical. Both materials enhance product protection but Mylar's clarity and tensile strength offer added benefits in consumer packaging, while aluminum foil's conductivity supports specialized industrial uses.

Environmental Impact and Recyclability

Mylar coating offers superior environmental benefits compared to aluminum foil coating due to its lower energy consumption during production and higher recyclability rates. Unlike aluminum foil, which requires intensive mining and smelting processes that contribute to significant greenhouse gas emissions, Mylar is primarily made from polyethylene terephthalate (PET), a recyclable plastic that reduces landfill waste and supports circular economy initiatives. Mylar's lightweight and durable properties also enhance resource efficiency and decrease transportation emissions compared to heavier aluminum foil alternatives.

Mylar Coating vs Aluminum Foil Coating Infographic

materialdif.com

materialdif.com