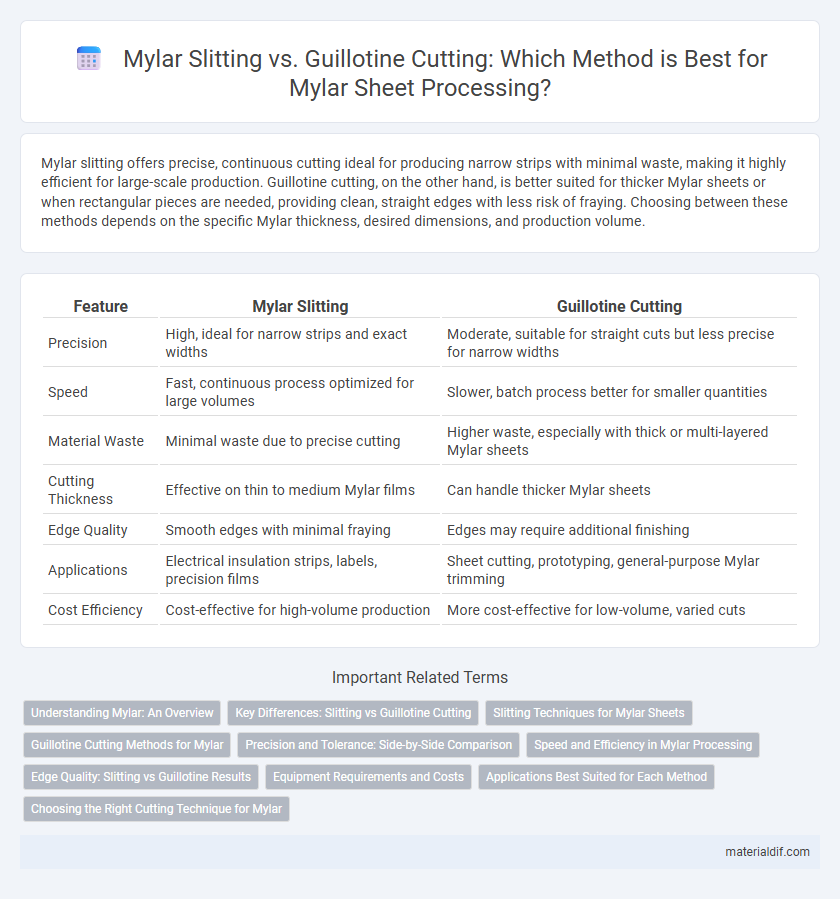

Mylar slitting offers precise, continuous cutting ideal for producing narrow strips with minimal waste, making it highly efficient for large-scale production. Guillotine cutting, on the other hand, is better suited for thicker Mylar sheets or when rectangular pieces are needed, providing clean, straight edges with less risk of fraying. Choosing between these methods depends on the specific Mylar thickness, desired dimensions, and production volume.

Table of Comparison

| Feature | Mylar Slitting | Guillotine Cutting |

|---|---|---|

| Precision | High, ideal for narrow strips and exact widths | Moderate, suitable for straight cuts but less precise for narrow widths |

| Speed | Fast, continuous process optimized for large volumes | Slower, batch process better for smaller quantities |

| Material Waste | Minimal waste due to precise cutting | Higher waste, especially with thick or multi-layered Mylar sheets |

| Cutting Thickness | Effective on thin to medium Mylar films | Can handle thicker Mylar sheets |

| Edge Quality | Smooth edges with minimal fraying | Edges may require additional finishing |

| Applications | Electrical insulation strips, labels, precision films | Sheet cutting, prototyping, general-purpose Mylar trimming |

| Cost Efficiency | Cost-effective for high-volume production | More cost-effective for low-volume, varied cuts |

Understanding Mylar: An Overview

Mylar slitting involves precisely slicing rolls of polyester film into narrower widths, offering clean edges and minimal waste ideal for packaging and insulation applications. Guillotine cutting, in contrast, uses a straight blade to cut stacked sheets of Mylar, suitable for bulk sheet processing but less precise for continuous rolls. Selecting between slitting and guillotine cutting hinges on production needs, material dimensions, and tolerance requirements specific to Mylar film products.

Key Differences: Slitting vs Guillotine Cutting

Mylar slitting involves cutting large rolls of film into narrower strips using rotary blades, ensuring continuous, precise, and efficient processing ideal for high-volume production. Guillotine cutting, by contrast, utilizes a straight blade to chop Mylar sheets into fixed sizes, providing clean cuts but limited to batch processing and less suitable for roll materials. The key differences lie in slitting's scalability and speed for roll films versus guillotine cutting's accuracy for sheet formats.

Slitting Techniques for Mylar Sheets

Mylar slitting techniques utilize precision rotary blades to create clean, uniform edges essential for high-quality packaging and insulation applications. This method offers continuous processing of wide Mylar rolls, enhancing efficiency and reducing material waste compared to guillotine cutting, which is better suited for batch cutting but can cause edge deformation. Advanced slitting machines incorporate tension control and blade positioning systems to ensure precise width specifications and smooth surface finishes on Mylar sheets.

Guillotine Cutting Methods for Mylar

Guillotine cutting methods for Mylar involve precise, straight-edge shearing techniques ideal for producing clean, sharp edges on sheets and rolls. This method enhances accuracy and reduces material waste compared to other cutting options, making it suitable for applications requiring uniform dimensions. Guillotine cutters with adjustable blades accommodate varying thicknesses of Mylar films, ensuring consistent quality in packaging, insulation, and protective films.

Precision and Tolerance: Side-by-Side Comparison

Mylar slitting offers superior precision and tighter tolerance levels compared to guillotine cutting, delivering clean, consistent edges crucial for high-performance applications. The continuous rotary action in slitting maintains uniform tension and minimal material distortion, ensuring dimensional accuracy within +-0.1 mm. In contrast, guillotine cutting can cause slight misalignments and edge fraying due to its batch cutting method, typically resulting in tolerances of +-0.3 mm.

Speed and Efficiency in Mylar Processing

Mylar slitting offers superior speed and efficiency compared to guillotine cutting by enabling continuous rolls to be cut into narrower strips without stopping production, significantly reducing downtime. This method allows for precise, high-volume processing ideal for large-scale industrial applications, whereas guillotine cutting is more suited for batch or sheet cutting with slower output. Automated slitting machines optimize material use and minimize waste, enhancing overall productivity in Mylar processing operations.

Edge Quality: Slitting vs Guillotine Results

Mylar slitting produces clean, smooth edges with minimal fraying and consistent width, ideal for applications requiring precise tolerances. Guillotine cutting can cause slight edge roughness and potential micro-cracks due to blade impact, affecting the material's integrity in high-stress uses. For superior edge quality, slitting is preferred over guillotine cutting in processing Mylar films.

Equipment Requirements and Costs

Mylar slitting equipment typically demands high-precision rotary blades and automated tension control systems, leading to higher initial investment but greater efficiency for long, continuous rolls. Guillotine cutting machines require robust shearing blades and manual or semi-automated feed systems, which generally incur lower upfront costs but may increase labor expenses and reduce throughput. The choice between slitting and guillotine cutting impacts overall production costs, balancing equipment complexity against operational efficiency in Mylar processing.

Applications Best Suited for Each Method

Mylar slitting offers precise, narrow cuts ideal for applications requiring continuous rolls, such as electrical insulation tapes, flexible printed circuits, and packaging films. Guillotine cutting suits bulk processing tasks where large sheets are divided into smaller panels, commonly used for printing substrates and laminated Mylar sheets. Selecting the appropriate technique depends on production volume, cut dimensions, and material thickness to optimize workflow and minimize waste.

Choosing the Right Cutting Technique for Mylar

Choosing the right cutting technique for Mylar depends on the material's thickness and desired precision. Mylar slitting offers clean, continuous cuts ideal for long rolls and mass production, preserving material integrity and minimizing waste. Guillotine cutting suits thicker Mylar sheets requiring straight, precise edges but may cause more waste and is less efficient for high-volume applications.

Mylar Slitting vs Guillotine Cutting Infographic

materialdif.com

materialdif.com