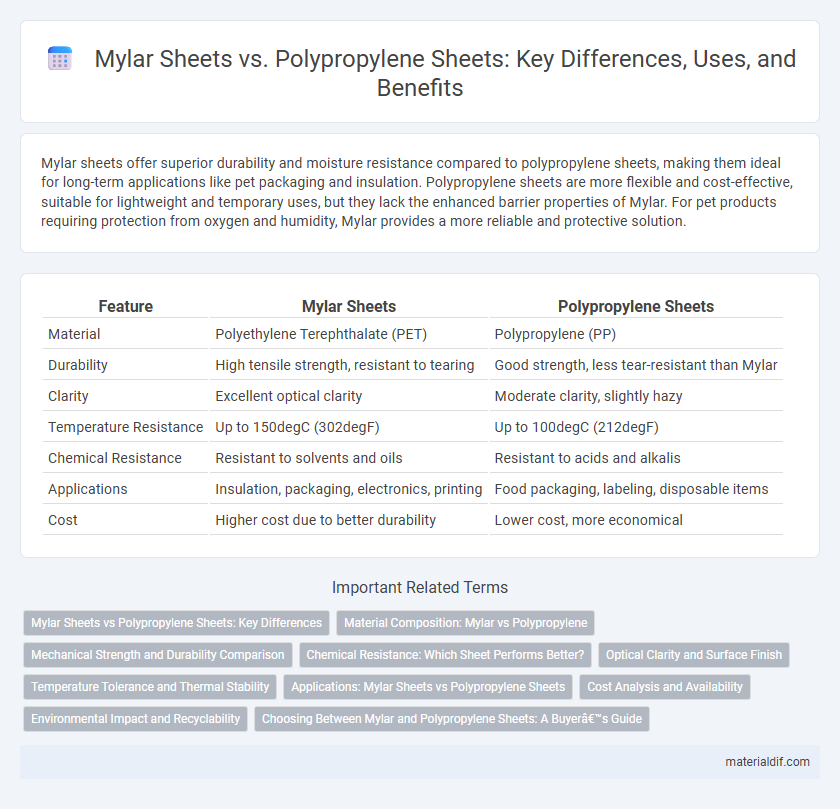

Mylar sheets offer superior durability and moisture resistance compared to polypropylene sheets, making them ideal for long-term applications like pet packaging and insulation. Polypropylene sheets are more flexible and cost-effective, suitable for lightweight and temporary uses, but they lack the enhanced barrier properties of Mylar. For pet products requiring protection from oxygen and humidity, Mylar provides a more reliable and protective solution.

Table of Comparison

| Feature | Mylar Sheets | Polypropylene Sheets |

|---|---|---|

| Material | Polyethylene Terephthalate (PET) | Polypropylene (PP) |

| Durability | High tensile strength, resistant to tearing | Good strength, less tear-resistant than Mylar |

| Clarity | Excellent optical clarity | Moderate clarity, slightly hazy |

| Temperature Resistance | Up to 150degC (302degF) | Up to 100degC (212degF) |

| Chemical Resistance | Resistant to solvents and oils | Resistant to acids and alkalis |

| Applications | Insulation, packaging, electronics, printing | Food packaging, labeling, disposable items |

| Cost | Higher cost due to better durability | Lower cost, more economical |

Mylar Sheets vs Polypropylene Sheets: Key Differences

Mylar sheets, made from stretched polyethylene terephthalate (PET), offer superior tensile strength, clarity, and chemical resistance compared to polypropylene sheets, which are more flexible and moisture-resistant but less durable. Mylar excels in applications requiring dimensional stability and excellent heat resistance, while polypropylene is preferred for cost-effective packaging and moisture barrier uses. Understanding these differences helps in selecting the right material for specific industrial, packaging, or crafting needs.

Material Composition: Mylar vs Polypropylene

Mylar sheets are made from stretched polyethylene terephthalate (PET), offering high tensile strength and superior barrier properties against moisture and gases. Polypropylene sheets consist of a thermoplastic polymer known for its flexibility, chemical resistance, and lower density compared to Mylar. The chemical structure of Mylar provides enhanced durability and thermal stability, while polypropylene excels in cost-effectiveness and impact resistance.

Mechanical Strength and Durability Comparison

Mylar sheets exhibit superior mechanical strength compared to polypropylene sheets, offering higher tensile strength and better resistance to stretching and tearing. The inherent chemical stability and dimensional stability of Mylar enhance its durability under stress and exposure to varying environmental conditions. Polypropylene sheets are more prone to deformation and wear over time, making Mylar the preferred choice for applications demanding long-lasting mechanical performance.

Chemical Resistance: Which Sheet Performs Better?

Mylar sheets exhibit superior chemical resistance compared to polypropylene sheets, especially against solvents, oils, and acids, making them ideal for harsh chemical environments. Polypropylene sheets offer good resistance to alkalis and some acids but tend to degrade faster when exposed to strong solvents. For applications requiring long-term durability against aggressive chemicals, Mylar sheets provide enhanced stability and reliability.

Optical Clarity and Surface Finish

Mylar sheets offer superior optical clarity compared to polypropylene sheets, making them ideal for applications requiring high transparency and minimal light distortion. The surface finish of Mylar is smooth and glossy, enhancing its reflective properties and providing a premium look. In contrast, polypropylene sheets typically have a matte finish with lower clarity, better suited for applications where durability and chemical resistance are prioritized over optical performance.

Temperature Tolerance and Thermal Stability

Mylar sheets exhibit superior temperature tolerance and thermal stability compared to polypropylene sheets, maintaining structural integrity at temperatures up to 150degC, whereas polypropylene typically withstands only up to 100degC. The enhanced thermal resistance of Mylar makes it ideal for applications requiring prolonged exposure to heat without deformation or loss of mechanical strength. Polypropylene sheets, while cost-effective, are more prone to melting and warping under higher temperatures, limiting their use in high-temperature environments.

Applications: Mylar Sheets vs Polypropylene Sheets

Mylar sheets excel in applications requiring high tensile strength, chemical resistance, and electrical insulation, making them ideal for electronics, packaging, and insulation uses. Polypropylene sheets offer superior flexibility and moisture resistance, commonly used in food packaging, automotive parts, and medical devices. Choosing between Mylar and polypropylene sheets depends on the specific application demands for durability, transparency, and environmental resistance.

Cost Analysis and Availability

Mylar sheets generally cost more than polypropylene sheets due to their superior durability and heat resistance, making them a preferred choice for high-performance packaging and insulation applications. Polypropylene sheets are widely available and cheaper, benefiting from extensive manufacturing and distribution channels that make them accessible for large-scale, cost-sensitive projects. The cost difference is balanced by the intended use; Mylar offers premium features at a premium price, while polypropylene provides budget-friendly versatility.

Environmental Impact and Recyclability

Mylar sheets, made from biaxially-oriented polyethylene terephthalate (BoPET), offer superior durability and are recyclable through specialized facilities, contributing to reduced environmental impact compared to polypropylene sheets, which are less commonly recycled and often end up in landfills. Polypropylene sheets, although lightweight and cost-effective, have lower heat resistance and commonly cause more significant environmental pollution due to limited recycling infrastructure. Choosing Mylar sheets supports sustainability efforts by leveraging their higher recyclability rate and longer lifecycle, minimizing plastic waste accumulation.

Choosing Between Mylar and Polypropylene Sheets: A Buyer’s Guide

Mylar sheets offer superior tensile strength, chemical resistance, and dimensional stability, making them ideal for archival storage, protective coverings, and electrical insulation. Polypropylene sheets provide excellent moisture resistance, flexibility, and cost-effectiveness, suitable for packaging, food containers, and automotive parts. Buyers should evaluate application requirements, durability needs, transparency, and budget constraints when choosing between Mylar and polypropylene sheets.

Mylar Sheets vs Polypropylene Sheets Infographic

materialdif.com

materialdif.com