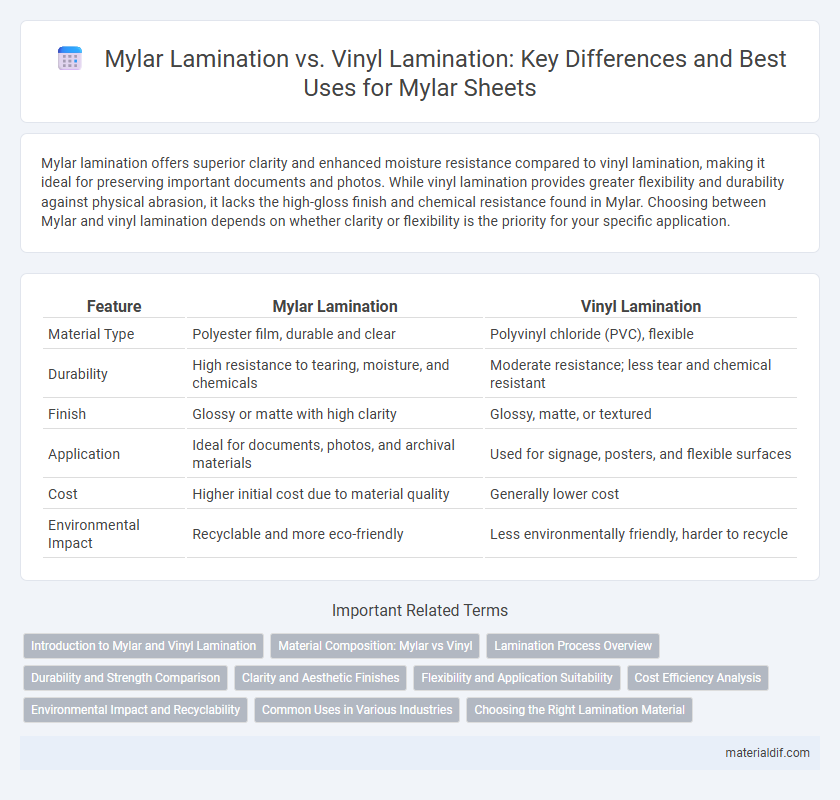

Mylar lamination offers superior clarity and enhanced moisture resistance compared to vinyl lamination, making it ideal for preserving important documents and photos. While vinyl lamination provides greater flexibility and durability against physical abrasion, it lacks the high-gloss finish and chemical resistance found in Mylar. Choosing between Mylar and vinyl lamination depends on whether clarity or flexibility is the priority for your specific application.

Table of Comparison

| Feature | Mylar Lamination | Vinyl Lamination |

|---|---|---|

| Material Type | Polyester film, durable and clear | Polyvinyl chloride (PVC), flexible |

| Durability | High resistance to tearing, moisture, and chemicals | Moderate resistance; less tear and chemical resistant |

| Finish | Glossy or matte with high clarity | Glossy, matte, or textured |

| Application | Ideal for documents, photos, and archival materials | Used for signage, posters, and flexible surfaces |

| Cost | Higher initial cost due to material quality | Generally lower cost |

| Environmental Impact | Recyclable and more eco-friendly | Less environmentally friendly, harder to recycle |

Introduction to Mylar and Vinyl Lamination

Mylar lamination uses polyester film known for high tensile strength, chemical stability, and clarity, making it ideal for protecting documents and artwork while enhancing durability and appearance. Vinyl lamination involves flexible PVC film, providing robust water resistance and surface protection with a slightly glossy or matte finish suitable for outdoor applications. Both processes improve printed materials but differ in material properties, cost, and optimal use cases based on environmental exposure and longevity requirements.

Material Composition: Mylar vs Vinyl

Mylar lamination consists of biaxially-oriented polyethylene terephthalate (BoPET), offering exceptional tensile strength, clarity, and temperature resistance. Vinyl lamination is made from polyvinyl chloride (PVC), providing flexibility and a thicker, more durable finish but with less clarity compared to Mylar. The distinct material compositions impact longevity, gloss levels, and protection, with Mylar excelling in resistance to moisture and UV degradation while vinyl prioritizes enhanced tactile durability.

Lamination Process Overview

Mylar lamination utilizes a polyester film known for its high tensile strength and clarity, which is heat-sealed onto printed materials to provide durable, water-resistant protection. Vinyl lamination involves applying a slightly thicker, more flexible plastic film that offers enhanced wrinkle resistance and a glossy finish through an adhesive bonding process. Both methods employ heat and pressure techniques, but Mylar lamination is preferred for archival quality and UV resistance, while vinyl lamination excels in flexibility and surface texture options.

Durability and Strength Comparison

Mylar lamination offers superior durability and strength compared to vinyl lamination, thanks to its polyester composition that resists tears, moisture, and UV damage effectively. Its high tensile strength ensures long-lasting protection for documents and artworks in demanding environments. Vinyl lamination, while flexible and cost-effective, tends to be less resistant to scratches and environmental wear, making Mylar the preferred choice for preserving valuable materials.

Clarity and Aesthetic Finishes

Mylar lamination offers superior clarity with its high-gloss, crystal-clear finish that preserves vivid colors and fine details, making it ideal for premium prints and photographs. Vinyl lamination provides a more flexible and durable protective layer but often results in a slightly muted or matte appearance, affecting the overall visual sharpness. For projects demanding exceptional aesthetic appeal and clarity, Mylar lamination is the preferred choice due to its smooth, reflective surface and resistance to yellowing over time.

Flexibility and Application Suitability

Mylar lamination offers superior flexibility, making it ideal for applications requiring frequent bending and durability, such as ID cards and flexible packaging. Vinyl lamination, while providing a thicker and more rigid protective layer, is better suited for flat surfaces and outdoor signage where weather resistance is crucial. Choosing between Mylar and vinyl lamination depends on the specific flexibility needs and the environmental conditions of the intended application.

Cost Efficiency Analysis

Mylar lamination typically offers superior cost efficiency compared to vinyl lamination due to its durability and resistance to moisture, which reduces replacement frequency and maintenance expenses. The initial investment for Mylar films may be higher, but their longer lifespan and clarity decrease overall lifecycle costs in printing and packaging applications. Vinyl lamination incurs lower upfront costs but often leads to higher long-term expenses due to susceptibility to scratches and environmental damage.

Environmental Impact and Recyclability

Mylar lamination offers superior environmental benefits compared to vinyl lamination due to its polyester base, which is more easily recyclable and produces less harmful waste during disposal. Vinyl lamination, made from PVC, poses significant environmental challenges because it releases toxic chemicals when incinerated and is difficult to recycle. Choosing Mylar lamination enhances sustainability by reducing landfill impact and supporting circular material life cycles in packaging and print protection.

Common Uses in Various Industries

Mylar lamination is widely used in the packaging industry for its superior clarity, durability, and resistance to moisture and chemicals, making it ideal for food wrappers, medical pouches, and electronic component packaging. Vinyl lamination, favored in printing and signage, offers flexibility and a glossy or matte finish that protects printed materials such as posters, book covers, and menus from scratches and UV damage. Both laminations are essential in retail, industrial, and advertising sectors, with Mylar preferred for high-barrier protection and vinyl chosen for aesthetic enhancement and surface protection.

Choosing the Right Lamination Material

Mylar lamination offers superior clarity, durability, and resistance to moisture compared to vinyl lamination, making it ideal for high-quality prints and long-lasting protection. Vinyl lamination provides flexibility and cost-effectiveness, suitable for applications requiring more pliability and budget constraints. Selecting the right lamination material depends on the end-use environment, desired finish, and longevity requirements to ensure optimal preservation and appearance.

Mylar Lamination vs Vinyl Lamination Infographic

materialdif.com

materialdif.com