Heat sealing Mylar creates a strong, airtight closure by applying continuous heat and pressure, ideal for long-term storage of pet food and treats. Impulse sealing Mylar uses short bursts of heat only when the sealer is activated, offering precise control and energy efficiency for frequent resealing needs. Choosing between the two depends on the sealing speed, consistency, and frequency required for preserving pet products.

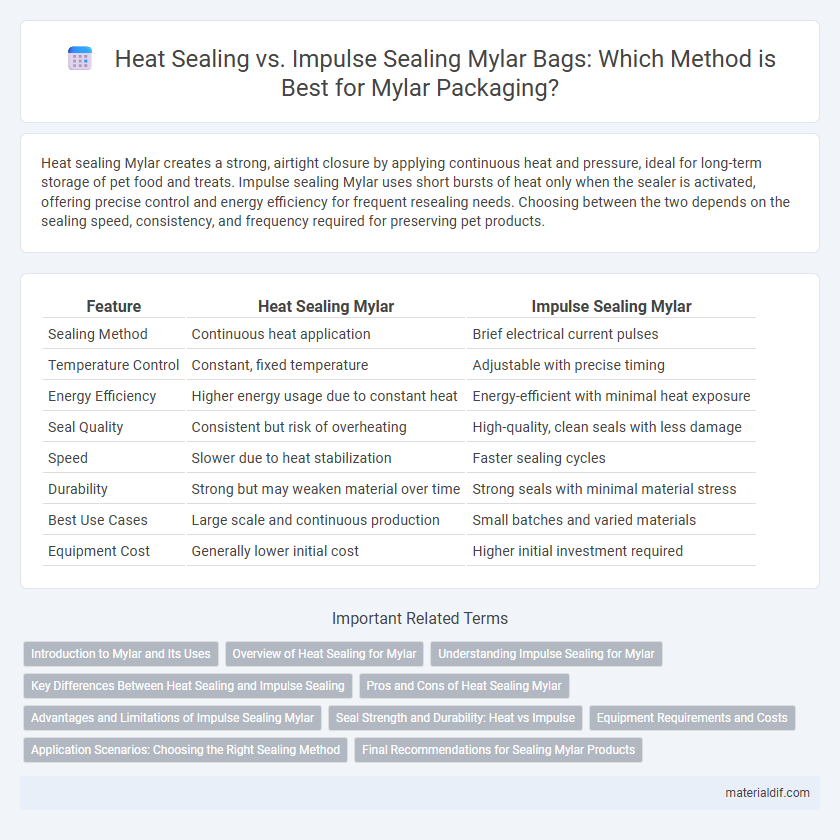

Table of Comparison

| Feature | Heat Sealing Mylar | Impulse Sealing Mylar |

|---|---|---|

| Sealing Method | Continuous heat application | Brief electrical current pulses |

| Temperature Control | Constant, fixed temperature | Adjustable with precise timing |

| Energy Efficiency | Higher energy usage due to constant heat | Energy-efficient with minimal heat exposure |

| Seal Quality | Consistent but risk of overheating | High-quality, clean seals with less damage |

| Speed | Slower due to heat stabilization | Faster sealing cycles |

| Durability | Strong but may weaken material over time | Strong seals with minimal material stress |

| Best Use Cases | Large scale and continuous production | Small batches and varied materials |

| Equipment Cost | Generally lower initial cost | Higher initial investment required |

Introduction to Mylar and Its Uses

Mylar, a durable polyester film known for its excellent barrier properties and tensile strength, is widely used in packaging, insulation, and protective applications. Heat sealing Mylar involves applying continuous heat and pressure to create a strong, uniform bond ideal for high-volume sealing processes. In contrast, impulse sealing uses short bursts of heat generated by an electric current, offering precise control and energy efficiency for delicate or low-volume packaging tasks.

Overview of Heat Sealing for Mylar

Heat sealing Mylar involves applying continuous heat and pressure to bond layers together, creating a strong, airtight seal essential for packaging sensitive products. This method ensures consistent temperature distribution, preventing material distortion and maintaining the integrity of the Mylar film. Heat sealing is widely preferred for its ability to produce durable seals suitable for long-term storage and protection against moisture and oxygen.

Understanding Impulse Sealing for Mylar

Impulse sealing for Mylar involves applying short bursts of heat through a heated wire element, creating precise, clean seals without continuous heat exposure, which preserves the integrity and appearance of the Mylar material. Unlike heat sealing that uses constant heat and pressure, impulse sealing minimizes the risk of melting or warping, making it ideal for Mylar bags intended for long-term storage and airtight packaging. This method enhances efficiency and durability in packaging applications, ensuring a strong, flexible seal tailored to the Mylar's heat-sensitive properties.

Key Differences Between Heat Sealing and Impulse Sealing

Heat sealing Mylar involves continuous application of heat and pressure to create a consistent, durable seal, ideal for long production runs where uniformity is crucial. Impulse sealing Mylar uses a rapid, targeted burst of heat that activates only during the sealing process, conserving energy and reducing thermal stress on the material. Key differences include the method of heat application, energy efficiency, and suitability for different production speeds and material thicknesses.

Pros and Cons of Heat Sealing Mylar

Heat sealing Mylar offers a strong, continuous seal ideal for packaging that requires airtight protection, with consistent heat application preventing leaks and contamination. However, it demands precise temperature control and longer cycle times, increasing energy consumption and potentially causing material damage if overheated. The method is less flexible for varying thicknesses and often requires specialized equipment, limiting its adaptability compared to impulse sealing.

Advantages and Limitations of Impulse Sealing Mylar

Impulse sealing Mylar offers precise temperature control and rapid heating, reducing the risk of material damage and enabling efficient, clean seals on delicate Mylar films. This method requires less energy compared to constant heat sealing, but its limitation lies in slower cycle times and potential inconsistency when sealing thicker or multi-layer Mylar materials. Impulse sealing machines are ideal for applications needing minimal thermal exposure, although they may struggle with high-volume production demands.

Seal Strength and Durability: Heat vs Impulse

Heat sealing Mylar creates a consistent, strong bond by applying continuous heat and pressure, enhancing seal strength and durability for long-term storage. Impulse sealing Mylar relies on rapid electrical heating, producing a fast seal but potentially less uniform strength, impacting durability under stress or extreme conditions. Choosing heat sealing results in superior seal integrity, essential for preserving product freshness and preventing contamination over extended periods.

Equipment Requirements and Costs

Heat sealing Mylar requires continuous heat application through heated bars or plates, necessitating equipment with precise temperature control and constant power supply, often resulting in higher energy consumption and maintenance costs. Impulse sealing uses a brief electric current to generate heat, allowing for simpler, energy-efficient machines with lower operating costs and less wear on sealing elements. Overall, impulse sealers tend to have lower initial equipment investment and reduced long-term expenses compared to the more complex heat sealing systems.

Application Scenarios: Choosing the Right Sealing Method

Heat sealing Mylar is ideal for continuous production lines requiring uniform, high-strength seals in packaging applications like food and medical products. Impulse sealing Mylar suits intermittent use cases or small-scale operations, providing precise control over seal temperature and duration, reducing material burns. Selecting the right method depends on production volume, seal integrity needs, and equipment compatibility.

Final Recommendations for Sealing Mylar Products

Heat sealing Mylar offers consistent, strong seals by applying continuous heat and pressure, ideal for bulk production with minimal edge distortion. Impulse sealing Mylar uses brief bursts of heat, conserving energy and reducing material stress, suitable for delicate or low-volume items. For optimal Mylar product sealing, choose heat sealing when durability and speed are priorities, while impulse sealing fits applications requiring precision and energy efficiency.

Heat Sealing Mylar vs Impulse Sealing Mylar Infographic

materialdif.com

materialdif.com