Clear Mylar offers superior transparency, making it ideal for applications where visibility of the product is essential, such as packaging that showcases contents. Metallized Mylar provides enhanced barrier properties against moisture, oxygen, and light, ensuring extended shelf life and protection. Choosing between Clear Mylar and Metallized Mylar depends on whether clarity or maximum preservation is the priority for your pet packaging needs.

Table of Comparison

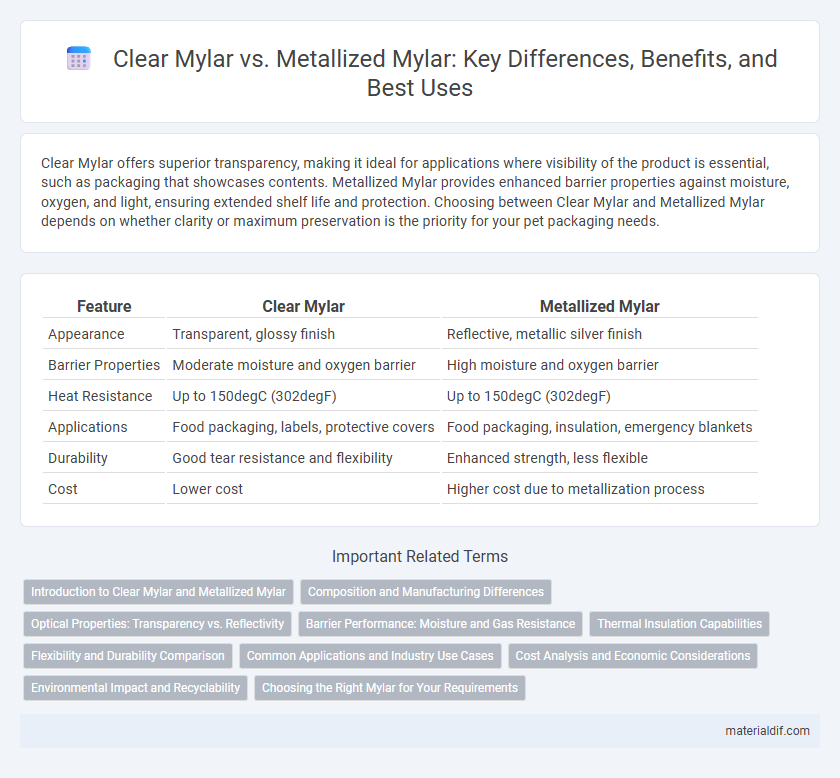

| Feature | Clear Mylar | Metallized Mylar |

|---|---|---|

| Appearance | Transparent, glossy finish | Reflective, metallic silver finish |

| Barrier Properties | Moderate moisture and oxygen barrier | High moisture and oxygen barrier |

| Heat Resistance | Up to 150degC (302degF) | Up to 150degC (302degF) |

| Applications | Food packaging, labels, protective covers | Food packaging, insulation, emergency blankets |

| Durability | Good tear resistance and flexibility | Enhanced strength, less flexible |

| Cost | Lower cost | Higher cost due to metallization process |

Introduction to Clear Mylar and Metallized Mylar

Clear Mylar is a transparent polyester film known for its excellent clarity, durability, and resistance to moisture, making it ideal for protective coverings and packaging. Metallized Mylar features a thin layer of metal, usually aluminum, deposited on the polyester base, offering enhanced reflectivity, barrier properties, and improved light and oxygen resistance. Both variants serve distinct purposes: Clear Mylar excels in visibility applications, while Metallized Mylar is preferred for insulation, decorative, and packaging uses requiring superior barrier performance.

Composition and Manufacturing Differences

Clear Mylar is composed of biaxially-oriented polyethylene terephthalate (BoPET) film, produced through a stretching process that enhances its strength and clarity. Metallized Mylar undergoes an additional step where a thin layer of metal, typically aluminum, is vacuum-deposited onto the BoPET film, providing reflective properties and improved barrier performance. The manufacturing difference lies in the metallization process, which significantly alters the film's optical and physical characteristics compared to the clear variant.

Optical Properties: Transparency vs. Reflectivity

Clear Mylar exhibits high transparency, allowing up to 90% light transmission, making it ideal for applications requiring visibility and clarity such as packaging and protective covers. Metallized Mylar, coated with a thin layer of metal like aluminum, boasts superior reflectivity, reflecting up to 97% of radiant energy, which enhances insulation and light diffusion in thermal blankets and grow rooms. The optical properties of Clear Mylar emphasize clarity and see-through quality, while Metallized Mylar prioritizes reflectance and energy conservation.

Barrier Performance: Moisture and Gas Resistance

Clear Mylar offers moderate moisture and gas barrier properties suitable for packaging applications where visibility is essential, but it allows higher permeability compared to Metallized Mylar. Metallized Mylar features a thin metal layer that significantly enhances moisture and gas resistance, making it ideal for sensitive food storage and electronic component protection. The metallization reduces oxygen and vapor transmission rates, extending shelf life and preserving product quality effectively.

Thermal Insulation Capabilities

Clear Mylar offers moderate thermal insulation by reflecting radiant heat while allowing visible light to pass through, making it suitable for applications needing light transmission and heat retention. Metallized Mylar enhances thermal insulation significantly due to its reflective metal coating, which reflects up to 97% of radiant heat and reduces heat transfer by radiation and convection. This superior heat reflectivity makes Metallized Mylar ideal for emergency blankets, insulation barriers, and thermal packaging where maximum heat retention or exclusion is required.

Flexibility and Durability Comparison

Clear Mylar offers superior flexibility due to its pure polyester composition, making it ideal for applications requiring frequent bending or folding without cracking. Metallized Mylar, coated with a thin metal layer, provides enhanced durability and resistance to moisture, punctures, and UV degradation but sacrifices some flexibility, becoming more rigid and prone to creasing under stress. Choosing between Clear and Metallized Mylar depends on the balance needed between flexibility for handling and the durability required for environmental protection.

Common Applications and Industry Use Cases

Clear Mylar is widely used in packaging, protective sleeves, and insulating materials due to its transparency and durability, making it ideal for food packaging, document protection, and electrical insulation. Metallized Mylar features a thin metal coating that enhances reflectivity and barrier properties, commonly utilized in thermal blankets, insulation panels, and decorative applications such as balloons and labels. Industries like aerospace, electronics, and food packaging rely on Metallized Mylar for its moisture resistance and thermal insulation, while Clear Mylar serves sectors requiring clarity and protection without opaque barriers.

Cost Analysis and Economic Considerations

Clear Mylar typically costs less due to simpler manufacturing processes and the absence of metal coating, making it a budget-friendly option for packaging and insulation. Metallized Mylar, while more expensive, offers enhanced barrier properties and durability, justifying its higher price in applications requiring moisture vapor and oxygen resistance. Economic considerations should weigh the initial cost against the functional benefits and lifespan of each type to determine the most cost-effective solution for specific industrial or commercial uses.

Environmental Impact and Recyclability

Clear Mylar, made from biaxially-oriented polyethylene terephthalate (BoPET), offers higher recyclability due to its single-polymer composition, reducing waste in recycling facilities. Metallized Mylar, coated with a thin layer of aluminum, presents environmental challenges because the metal layer complicates recycling processes and often leads to landfill disposal. The environmental impact of metallized Mylar is greater due to resource-intensive production and limited recyclability compared to clear Mylar's more sustainable life cycle.

Choosing the Right Mylar for Your Requirements

Clear Mylar offers transparency and excellent light diffusion, making it ideal for applications such as window insulation, packaging, and photo overlays, where visibility is crucial. Metallized Mylar contains a thin metal coating that enhances reflectivity, providing superior moisture resistance, durability, and thermal insulation, often used in emergency blankets, insulation, and decorative purposes. Choosing the right Mylar depends on whether your priority is visibility and light transmission or enhanced barrier properties and reflectivity tailored to specific environmental or functional requirements.

Clear Mylar vs Metallized Mylar Infographic

materialdif.com

materialdif.com