Mylar pet materials offer superior durability and resistance to moisture compared to vinyl, making them ideal for long-lasting applications. While vinyl is flexible and cost-effective, Mylar's tensile strength and clarity provide enhanced performance for protective and decorative uses. Choosing between Mylar and vinyl depends on the specific needs for resilience, transparency, and environmental exposure.

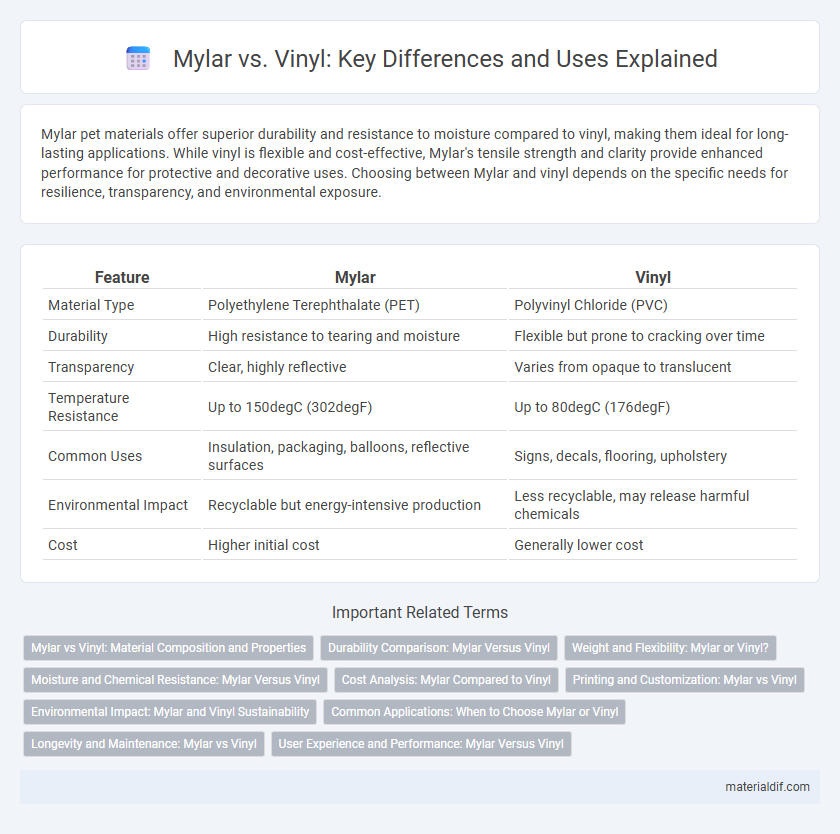

Table of Comparison

| Feature | Mylar | Vinyl |

|---|---|---|

| Material Type | Polyethylene Terephthalate (PET) | Polyvinyl Chloride (PVC) |

| Durability | High resistance to tearing and moisture | Flexible but prone to cracking over time |

| Transparency | Clear, highly reflective | Varies from opaque to translucent |

| Temperature Resistance | Up to 150degC (302degF) | Up to 80degC (176degF) |

| Common Uses | Insulation, packaging, balloons, reflective surfaces | Signs, decals, flooring, upholstery |

| Environmental Impact | Recyclable but energy-intensive production | Less recyclable, may release harmful chemicals |

| Cost | Higher initial cost | Generally lower cost |

Mylar vs Vinyl: Material Composition and Properties

Mylar is a polyester film known for its high tensile strength, dimensional stability, and resistance to moisture and chemicals, making it ideal for insulation and reflective applications. Vinyl, composed primarily of polyvinyl chloride (PVC), offers flexibility, durability, and weather resistance, commonly used in signage and upholstery. The key difference lies in Mylar's superior thermal resistance and low permeability compared to vinyl's toughness and adaptability to various surfaces.

Durability Comparison: Mylar Versus Vinyl

Mylar offers superior durability compared to vinyl due to its resistance to tearing, moisture, and UV exposure, making it ideal for long-term applications. Vinyl, while flexible and cost-effective, tends to degrade faster under harsh environmental conditions. The enhanced strength and weather resistance of Mylar ensure prolonged performance and reliability in both indoor and outdoor uses.

Weight and Flexibility: Mylar or Vinyl?

Mylar is significantly lighter than vinyl, making it ideal for applications where weight reduction is critical, such as in lightweight banners or emergency blankets. Vinyl tends to be thicker and less flexible, providing enhanced durability and resistance to tearing but limiting its use in projects requiring frequent bending or folding. The superior flexibility of Mylar supports easy manipulation and compact storage, whereas vinyl offers sturdiness at the cost of increased weight and reduced pliability.

Moisture and Chemical Resistance: Mylar Versus Vinyl

Mylar offers superior moisture resistance due to its polyester composition, making it less permeable to water vapor compared to vinyl, which is more susceptible to moisture absorption and degradation. Chemically, Mylar resists a broad range of solvents, acids, and alkalis, providing enhanced durability in harsh environments, whereas vinyl tends to weaken or discolor when exposed to certain chemicals. This makes Mylar the preferred choice for applications requiring long-term exposure to moisture and chemical agents.

Cost Analysis: Mylar Compared to Vinyl

Mylar offers a cost-effective alternative to vinyl, with prices typically 20-40% lower depending on thickness and quality. While vinyl provides durability and weather resistance, Mylar's lightweight and affordability make it ideal for budget-conscious projects. Overall, Mylar reduces material expenses without compromising flexibility in various applications.

Printing and Customization: Mylar vs Vinyl

Mylar offers superior print clarity and vibrant color retention compared to vinyl, making it ideal for high-quality custom graphics and detailed designs. Its smooth surface allows for precise ink adhesion, enhancing durability and resistance to fading over time. Vinyl, while versatile and cost-effective, often struggles with print sharpness and color vibrancy when subjected to intricate customization.

Environmental Impact: Mylar and Vinyl Sustainability

Mylar offers a more environmentally friendly alternative to vinyl due to its lower carbon footprint and higher recyclability, which reduces landfill waste and pollution. Vinyl production relies heavily on fossil fuels and releases harmful chemicals such as dioxins, contributing to air and water contamination. Choosing Mylar supports sustainability efforts by minimizing toxic emissions and promoting longer lifecycle usage through reuse and recycling programs.

Common Applications: When to Choose Mylar or Vinyl

Mylar is ideal for high-quality prints, packaging, and insulation due to its durability, clarity, and resistance to moisture and chemicals, making it a preferred choice for food packaging and protective covers. Vinyl excels in outdoor signage, banners, and vehicle wraps because of its flexibility, weather resistance, and ease of application on various surfaces. Choose Mylar for applications requiring long-term preservation and clarity, while Vinyl is better suited for vibrant, durable outdoor graphics and advertising materials.

Longevity and Maintenance: Mylar vs Vinyl

Mylar offers superior longevity compared to vinyl due to its resistance to moisture, UV rays, and temperature fluctuations, making it ideal for long-term applications. Maintenance of Mylar is minimal since it resists fading, cracking, and peeling, whereas vinyl often requires regular cleaning and can degrade faster under harsh environmental conditions. Choosing Mylar over vinyl ensures durability and low upkeep for projects exposed to outdoor or variable conditions.

User Experience and Performance: Mylar Versus Vinyl

Mylar offers superior dimensional stability and resistance to stretching compared to vinyl, enhancing durability in various applications. Users benefit from Mylar's higher clarity and smoother surface, which provide better print quality and tactile sensation. Vinyl, while more flexible and cost-effective, often falls short in longevity and resistance to environmental factors such as UV exposure and moisture.

Mylar vs Vinyl Infographic

materialdif.com

materialdif.com