Mylar offers superior moisture resistance and reflective properties compared to nylon, making it ideal for insulation and emergency blankets in pet care. Nylon is more durable and flexible, providing excellent strength for pet harnesses and leashes. Choosing between Mylar and nylon depends on whether moisture barrier or durability is the primary need in your pet products.

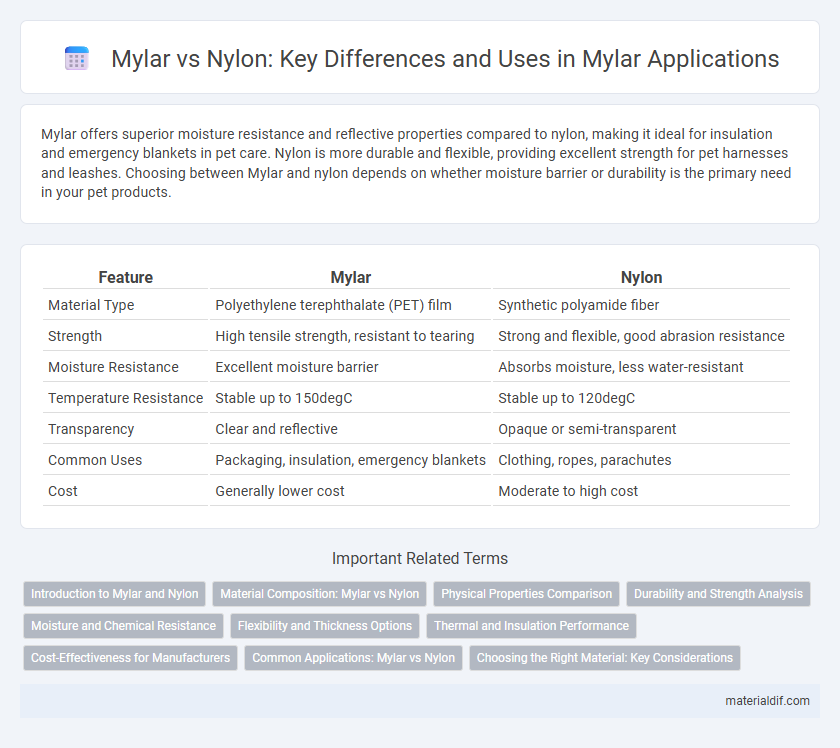

Table of Comparison

| Feature | Mylar | Nylon |

|---|---|---|

| Material Type | Polyethylene terephthalate (PET) film | Synthetic polyamide fiber |

| Strength | High tensile strength, resistant to tearing | Strong and flexible, good abrasion resistance |

| Moisture Resistance | Excellent moisture barrier | Absorbs moisture, less water-resistant |

| Temperature Resistance | Stable up to 150degC | Stable up to 120degC |

| Transparency | Clear and reflective | Opaque or semi-transparent |

| Common Uses | Packaging, insulation, emergency blankets | Clothing, ropes, parachutes |

| Cost | Generally lower cost | Moderate to high cost |

Introduction to Mylar and Nylon

Mylar is a polyester film known for its high tensile strength, chemical stability, and excellent barrier properties against moisture and gases, making it ideal for packaging and insulation applications. Nylon, a synthetic polyamide, offers robust mechanical strength, flexibility, and resistance to abrasion, frequently used in textiles, ropes, and industrial materials. Mylar's superior dimensional stability and barrier performance contrast with Nylon's elasticity and toughness, dictating their distinct uses in various industries.

Material Composition: Mylar vs Nylon

Mylar is a polyester film made from polyethylene terephthalate (PET), known for its high tensile strength, chemical stability, and excellent barrier properties against moisture and gases. Nylon, a synthetic polyamide, offers superior flexibility and abrasion resistance but is more permeable to water vapor compared to Mylar. The distinct molecular structures in Mylar's tightly packed polymer chains provide enhanced durability and impermeability, whereas Nylon's semi-crystalline structure yields greater elasticity and mechanical toughness.

Physical Properties Comparison

Mylar exhibits superior tensile strength and dimensional stability compared to nylon, making it more resistant to stretching and deformation under stress. Its excellent resistance to moisture and high-temperature tolerance enhances durability in harsh environments, whereas nylon tends to absorb water, leading to diminished mechanical performance. Mylar's low permeability to gases and chemicals further distinguishes it from nylon, which has higher permeability and reduced chemical resistance.

Durability and Strength Analysis

Mylar exhibits superior tensile strength and resistance to stretching compared to nylon, making it more durable under high-stress conditions. Its polyethylene terephthalate composition provides excellent resistance to abrasion, moisture, and chemical exposure, whereas nylon tends to degrade faster when exposed to UV light and moisture. These properties make Mylar an optimal choice for long-lasting applications requiring high strength and durability.

Moisture and Chemical Resistance

Mylar exhibits superior moisture resistance compared to nylon, making it ideal for applications requiring protection from water and humidity. Chemically, Mylar withstands exposure to solvents, acids, and alkalis better than nylon, ensuring durability in harsh environments. This combination of moisture and chemical resistance positions Mylar as a preferred material for packaging, insulation, and protective coatings.

Flexibility and Thickness Options

Mylar offers superior flexibility compared to Nylon, making it ideal for applications requiring repeated bending without material fatigue. It comes in a wide range of thickness options, from ultra-thin films to thicker sheets, allowing precise customization for various industrial uses. Nylon, while durable, tends to be less flexible and typically available in fewer thickness grades, limiting its adaptability in flexible film applications.

Thermal and Insulation Performance

Mylar outperforms nylon in thermal and insulation performance due to its superior reflectivity and low thermal conductivity, making it ideal for retaining heat in insulation applications. Mylar's metallized polyester film effectively reflects radiant heat, reducing heat transfer more efficiently than nylon, which is more prone to heat conduction. This makes Mylar the preferred choice for thermal blankets, emergency insulation, and reflective insulation barriers.

Cost-Effectiveness for Manufacturers

Mylar offers superior cost-effectiveness for manufacturers compared to nylon due to its lower production costs and higher durability, which reduces replacement frequency. Mylar's consistent quality and ease of processing decrease manufacturing downtime, enhancing overall efficiency. These factors make Mylar a preferred choice in industries prioritizing budget optimization without compromising material performance.

Common Applications: Mylar vs Nylon

Mylar is widely used in insulating materials, food packaging, and reflective surfaces due to its excellent barrier properties and dimensional stability, whereas nylon is favored in textiles, automotive components, and industrial applications for its high tensile strength and abrasion resistance. Mylar's moisture and chemical resistance make it ideal for electronic insulation and protective films, while nylon's flexibility and durability suit it for fabric production and mechanical parts. Both materials serve distinct roles based on performance requirements, with Mylar excelling in barrier and insulation applications and nylon dominating in structural and wear-resistant products.

Choosing the Right Material: Key Considerations

Mylar offers superior moisture and chemical resistance compared to nylon, making it ideal for applications requiring airtight and durable barriers. Nylon provides greater flexibility and tensile strength, suitable for wearables or flexible packaging where stretch and abrasion resistance are critical. Assessing factors such as environmental exposure, mechanical stress, and longevity requirements is essential when choosing between Mylar and nylon for optimal performance.

Mylar vs Nylon Infographic

materialdif.com

materialdif.com