Mylar offers superior reflective properties compared to polyester, making it highly effective for insulation and thermal retention in pet products. Unlike polyester, Mylar is made from stretched polyethylene terephthalate (PET) film, which provides enhanced durability and resistance to moisture. Both materials are lightweight, but Mylar's shiny surface helps regulate temperature more efficiently, benefiting pets in various environments.

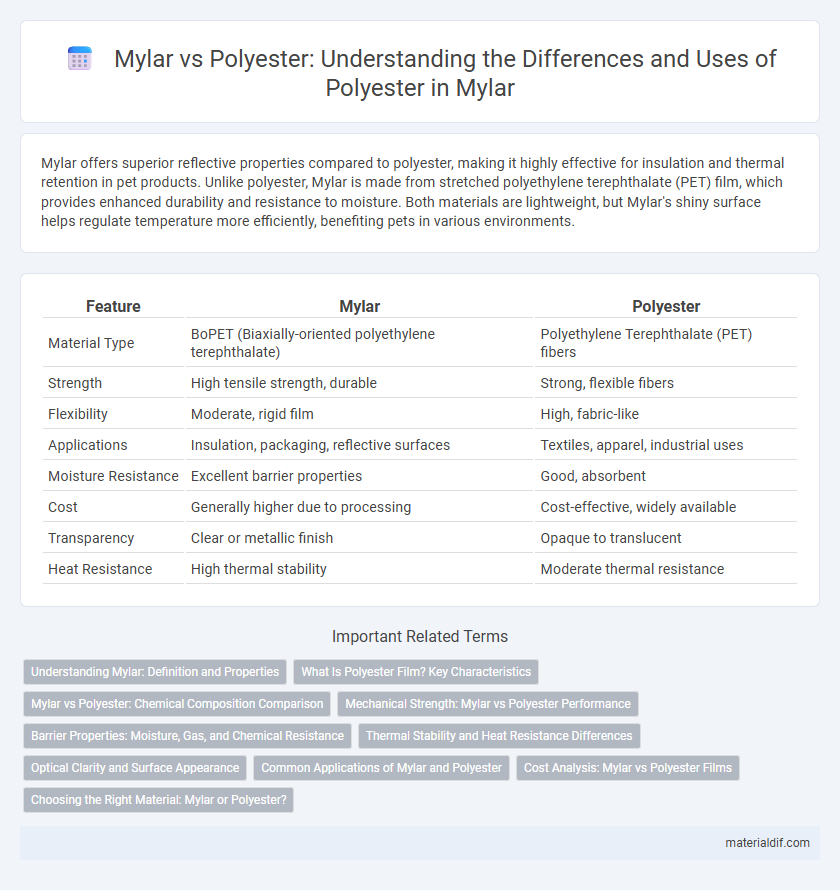

Table of Comparison

| Feature | Mylar | Polyester |

|---|---|---|

| Material Type | BoPET (Biaxially-oriented polyethylene terephthalate) | Polyethylene Terephthalate (PET) fibers |

| Strength | High tensile strength, durable | Strong, flexible fibers |

| Flexibility | Moderate, rigid film | High, fabric-like |

| Applications | Insulation, packaging, reflective surfaces | Textiles, apparel, industrial uses |

| Moisture Resistance | Excellent barrier properties | Good, absorbent |

| Cost | Generally higher due to processing | Cost-effective, widely available |

| Transparency | Clear or metallic finish | Opaque to translucent |

| Heat Resistance | High thermal stability | Moderate thermal resistance |

Understanding Mylar: Definition and Properties

Mylar is a brand name for biaxially oriented polyethylene terephthalate (BoPET), a type of polyester film known for its high tensile strength, chemical stability, and excellent barrier properties against moisture and gases. Unlike generic polyester films, Mylar undergoes a unique stretching process that enhances dimensional stability, clarity, and reflective qualities, making it ideal for applications in electronics, packaging, and insulation. Its ability to withstand extreme temperatures and resist stretching distinguishes Mylar from standard polyester films, providing superior durability and performance across various industries.

What Is Polyester Film? Key Characteristics

Polyester film, a versatile synthetic polymer made from polyethylene terephthalate (PET), offers exceptional strength, chemical resistance, and dimensional stability. Mylar is a brand name for biaxially oriented polyester film, known for its clarity, high tensile strength, and excellent electrical insulating properties. Both materials provide robust performance in packaging, electrical insulation, and imaging applications, with Mylar often preferred for its enhanced durability and consistency.

Mylar vs Polyester: Chemical Composition Comparison

Mylar is a brand name for biaxially-oriented polyethylene terephthalate (BoPET), a type of polyester film characterized by its exceptional tensile strength, chemical stability, and transparency. Unlike generic polyester films, Mylar undergoes a specialized stretching process that enhances its molecular orientation, resulting in superior durability and resistance to moisture and gases. The intrinsic chemical composition of Mylar and other polyester films primarily involves repeating units of terephthalic acid and ethylene glycol, but Mylar's optimized manufacturing process differentiates it in performance and application versatility.

Mechanical Strength: Mylar vs Polyester Performance

Mylar, a brand of biaxially-oriented polyethylene terephthalate (BoPET), exhibits superior mechanical strength compared to standard polyester films due to its enhanced tensile strength and high dimensional stability. This strength allows Mylar to withstand greater stress and strain without deformation, making it ideal for applications requiring durability under mechanical load. Polyester films, while strong, generally offer lower tensile strength and flexibility, resulting in reduced performance in high-stress environments compared to Mylar.

Barrier Properties: Moisture, Gas, and Chemical Resistance

Mylar, a brand of biaxially oriented polyethylene terephthalate (BoPET), exhibits superior barrier properties compared to standard polyester films, particularly in moisture and gas resistance. Its dense molecular structure provides enhanced protection against oxygen and water vapor transmission, making it ideal for packaging sensitive products. Additionally, Mylar offers excellent chemical resistance, maintaining integrity in harsh environments where other polyester films may degrade.

Thermal Stability and Heat Resistance Differences

Mylar, a brand of biaxially-oriented polyethylene terephthalate (BoPET), exhibits superior thermal stability and heat resistance compared to generic polyester films due to its enhanced molecular orientation and crystallinity. Mylar can withstand continuous temperatures up to approximately 150degC, while standard polyester films typically endure lower heat limits, around 120degC to 130degC. This higher thermal tolerance makes Mylar ideal for applications requiring long-term exposure to elevated temperatures without deformation or loss of mechanical properties.

Optical Clarity and Surface Appearance

Mylar, a brand of biaxially-oriented polyethylene terephthalate (BoPET), offers superior optical clarity compared to standard polyester films, making it ideal for applications requiring high transparency. The surface appearance of Mylar is exceptionally smooth and glossy, providing enhanced light reflectance and a consistent finish. Polyester films, while durable, often have a slightly matte or less uniform surface texture, which can affect visual clarity and overall aesthetic quality.

Common Applications of Mylar and Polyester

Mylar, a brand of biaxially-oriented polyethylene terephthalate (BoPET), is commonly used in insulation, packaging, and reflective surfaces due to its high tensile strength, chemical stability, and reflective properties. Polyester films, more broadly, find applications in flexible electronics, magnetic tapes, and solar panels, where durability and electrical insulation are crucial. Both materials are favored in the manufacturing of graphic arts and magnetic media but Mylar's superior clarity and durability make it preferred for photographic and archiving applications.

Cost Analysis: Mylar vs Polyester Films

Mylar films, a brand of biaxially-oriented polyethylene terephthalate (BoPET), generally offer a cost-effective alternative to generic polyester films due to their specialized manufacturing processes and branded quality assurance. While both Mylar and standard polyester films provide excellent tensile strength and chemical stability, Mylar's higher initial price is often offset by its superior durability and longer lifespan in applications such as electrical insulation and packaging. Cost analysis reveals that although polyester films may appear cheaper upfront, Mylar's enhanced performance reduces replacement frequency and overall lifecycle expenses.

Choosing the Right Material: Mylar or Polyester?

Mylar, a brand of biaxially-oriented polyethylene terephthalate (BoPET), offers superior tensile strength, chemical stability, and reflective qualities compared to standard polyester films, making it ideal for applications requiring durability and high thermal resistance. Polyester films, while also made from PET, generally provide better flexibility and lower cost, suitable for packaging, laminating, and insulation purposes where moderate strength and clarity are sufficient. Selecting between Mylar and polyester depends on specific needs such as heat resistance, clarity, strength, and budget constraints, guiding users to prioritize Mylar for high-performance uses and polyester for cost-effective solutions.

Mylar vs Polyester Infographic

materialdif.com

materialdif.com