Mylar film offers superior flexibility and is commonly used for wrapping and insulating applications due to its thin, lightweight nature. Mylar sheets are thicker, providing enhanced durability and rigidity, making them ideal for protective coverings and structural uses. Choosing between Mylar film and Mylar sheet depends on the specific requirements for strength, flexibility, and application environment.

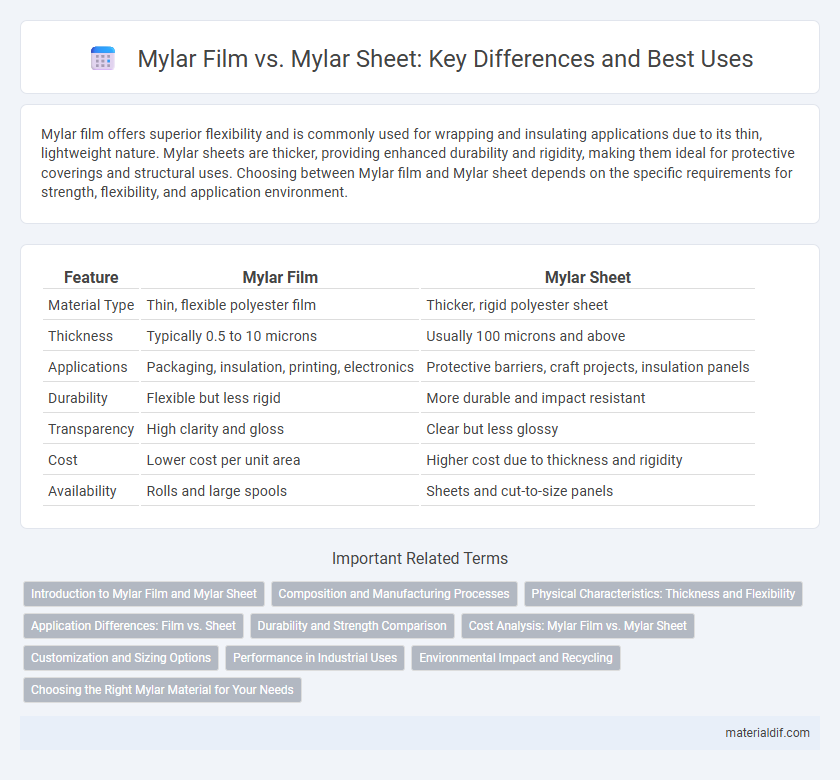

Table of Comparison

| Feature | Mylar Film | Mylar Sheet |

|---|---|---|

| Material Type | Thin, flexible polyester film | Thicker, rigid polyester sheet |

| Thickness | Typically 0.5 to 10 microns | Usually 100 microns and above |

| Applications | Packaging, insulation, printing, electronics | Protective barriers, craft projects, insulation panels |

| Durability | Flexible but less rigid | More durable and impact resistant |

| Transparency | High clarity and gloss | Clear but less glossy |

| Cost | Lower cost per unit area | Higher cost due to thickness and rigidity |

| Availability | Rolls and large spools | Sheets and cut-to-size panels |

Introduction to Mylar Film and Mylar Sheet

Mylar film is a thin, flexible polyester film widely used for packaging, insulation, and protective coatings due to its high tensile strength and chemical stability. Mylar sheets are thicker and more rigid, often utilized in applications requiring structural support, such as stiffeners, gaskets, and durable covers. Both forms share excellent electrical insulation properties and moisture resistance, but Mylar film is preferred for lightweight, transparent uses, while sheets provide enhanced mechanical durability.

Composition and Manufacturing Processes

Mylar film and Mylar sheet are both made from biaxially oriented polyethylene terephthalate (BoPET), offering high tensile strength and excellent dimensional stability. Mylar film undergoes a precise extrusion and biaxial orientation process, resulting in a thin, flexible material ideal for packaging and insulation applications. In contrast, Mylar sheets are thicker, produced through calendering or casting methods to achieve rigidity, making them suitable for structural uses and protective barriers.

Physical Characteristics: Thickness and Flexibility

Mylar film typically offers thinner thickness options ranging from 12 to 100 microns, providing superior flexibility suitable for applications requiring tight bends and conformability. Mylar sheets, in contrast, are thicker, usually starting at 100 microns and extending beyond 250 microns, delivering increased rigidity and durability for structural and protective uses. The choice between film and sheet depends on balancing flexibility needs against the required mechanical strength in the final application.

Application Differences: Film vs. Sheet

Mylar film offers superior flexibility and transparency, making it ideal for applications like packaging, graphics, and electronics insulation where thin, lightweight material is essential. Mylar sheet provides greater rigidity and durability, suited for structural uses such as protective covers, insulation panels, and static shielding in industrial and architectural contexts. Choosing between Mylar film and sheet depends on the need for flexibility versus stiffness, as well as the specific environmental and mechanical demands of the application.

Durability and Strength Comparison

Mylar film offers superior tensile strength and puncture resistance compared to Mylar sheets, making it ideal for applications requiring flexibility and durability. The thin, polyester-based Mylar film resists tearing and stretching under stress, while Mylar sheets, being thicker, provide enhanced rigidity but are more susceptible to cracking under heavy impact. In terms of longevity, Mylar film maintains its strength and clarity better over time, resisting degradation from UV exposure and moisture more effectively than the bulkier Mylar sheets.

Cost Analysis: Mylar Film vs. Mylar Sheet

Mylar film generally offers a more cost-effective solution due to its thinner, flexible nature, which reduces material usage and shipping expenses compared to the thicker, heavier Mylar sheet. Manufacturing processes for Mylar film benefit from economies of scale, further lowering per-unit prices relative to Mylar sheets, which require more raw materials and processing time. When evaluating applications, the cost difference can be significant depending on the required durability, thickness, and surface finish of the Mylar product.

Customization and Sizing Options

Mylar film offers greater customization with precise thickness control and is ideal for applications requiring flexible, thin layers, while Mylar sheets provide rigid, uniform sizing options suited for structural uses. Custom Mylar films can be produced in various widths and lengths to meet specific project demands, whereas Mylar sheets are typically available in standard sizes but can be cut to custom dimensions. This makes Mylar film preferable for intricate, high-precision tasks, while Mylar sheets are better for durable, larger-scale applications.

Performance in Industrial Uses

Mylar film offers superior tensile strength and flexibility compared to Mylar sheets, making it ideal for industrial applications requiring durability and precision. Its thin, uniform structure enhances insulating properties and resistance to chemicals and moisture, critical for electronics and packaging industries. Mylar sheets, while thicker and more rigid, provide excellent dimensional stability and are preferred in applications needing structural support or protective layers.

Environmental Impact and Recycling

Mylar film is thinner and more flexible, making it easier to recycle compared to thicker Mylar sheets, which require specialized processing due to their rigidity. Both forms are made from biaxially oriented polyethylene terephthalate (BoPET), a polyester that is recyclable but demands proper sorting to avoid contamination. The environmental impact of Mylar products largely depends on disposal methods, with recycling facilities favoring films for their lower material volume and better breakdown efficiency.

Choosing the Right Mylar Material for Your Needs

Mylar film offers superior flexibility and clarity, making it ideal for applications requiring lightweight, transparent materials such as packaging and insulation. Mylar sheets provide greater durability and thickness, suited for more robust uses like protective covers and crafting. Selecting between Mylar film and Mylar sheets depends on the specific requirements for rigidity, transparency, and durability in your project.

Mylar Film vs Mylar Sheet Infographic

materialdif.com

materialdif.com