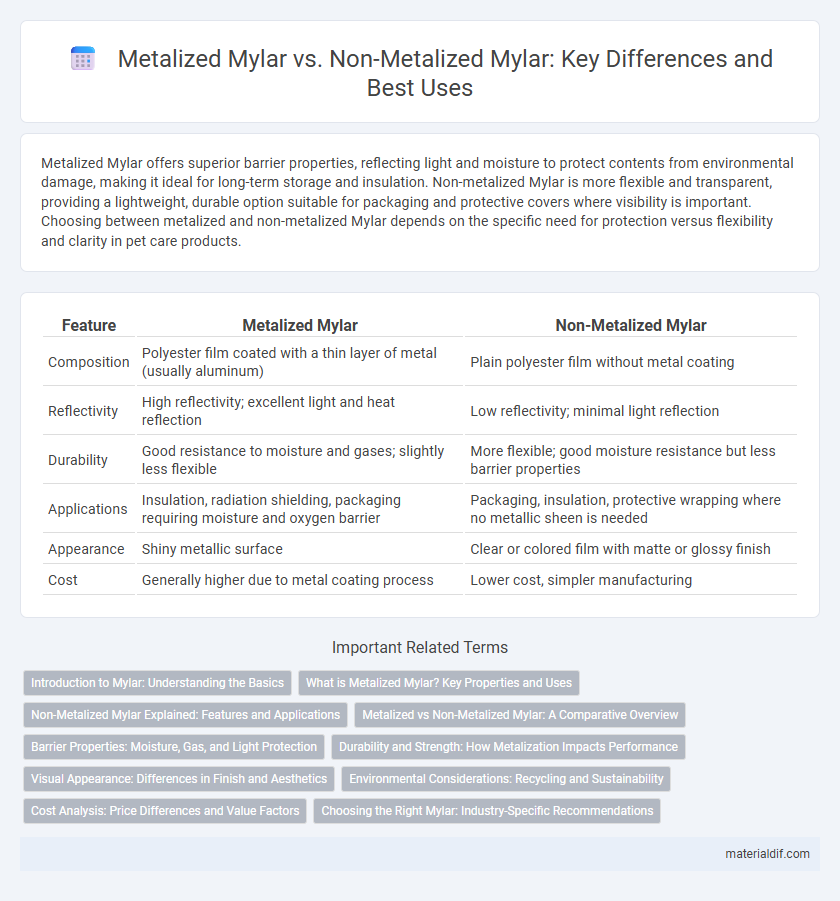

Metalized Mylar offers superior barrier properties, reflecting light and moisture to protect contents from environmental damage, making it ideal for long-term storage and insulation. Non-metalized Mylar is more flexible and transparent, providing a lightweight, durable option suitable for packaging and protective covers where visibility is important. Choosing between metalized and non-metalized Mylar depends on the specific need for protection versus flexibility and clarity in pet care products.

Table of Comparison

| Feature | Metalized Mylar | Non-Metalized Mylar |

|---|---|---|

| Composition | Polyester film coated with a thin layer of metal (usually aluminum) | Plain polyester film without metal coating |

| Reflectivity | High reflectivity; excellent light and heat reflection | Low reflectivity; minimal light reflection |

| Durability | Good resistance to moisture and gases; slightly less flexible | More flexible; good moisture resistance but less barrier properties |

| Applications | Insulation, radiation shielding, packaging requiring moisture and oxygen barrier | Packaging, insulation, protective wrapping where no metallic sheen is needed |

| Appearance | Shiny metallic surface | Clear or colored film with matte or glossy finish |

| Cost | Generally higher due to metal coating process | Lower cost, simpler manufacturing |

Introduction to Mylar: Understanding the Basics

Mylar is a polyester film known for its durability, flexibility, and chemical stability, commonly used in packaging, insulation, and electronics. Metalized Mylar features a thin layer of metal, typically aluminum, which enhances its reflective properties, moisture resistance, and barrier capabilities against gases and light. Non-metalized Mylar lacks this metal coating, offering transparency and high tensile strength while maintaining flexibility for diverse applications where reflectivity is not required.

What is Metalized Mylar? Key Properties and Uses

Metalized Mylar is a polyester film coated with a thin layer of metal, usually aluminum, enhancing its reflective properties, durability, and barrier resistance. Key properties include high tensile strength, excellent moisture and gas barrier, and superior light reflectivity, making it ideal for insulation, packaging, and emergency blankets. Common uses span thermal insulation in spacecraft, food packaging to extend shelf life, and decorative applications requiring a shiny, reflective surface.

Non-Metalized Mylar Explained: Features and Applications

Non-metalized Mylar, made from biaxially oriented polyethylene terephthalate (BoPET), offers transparent, flexible, and durable properties without the reflective metallic coating of metalized Mylar. Its high tensile strength, chemical stability, and excellent electrical insulation make it ideal for applications in packaging, insulation, and protective covers in electronics. Non-metalized Mylar is favored for scenarios requiring clear visibility or breathability, such as food packaging and graphic arts, where non-reflective, moisture-resistant materials are essential.

Metalized vs Non-Metalized Mylar: A Comparative Overview

Metalized Mylar features a thin layer of metal, usually aluminum, which enhances its reflective properties, making it ideal for insulation, emergency blankets, and decorative purposes. Non-metalized Mylar lacks this coating, offering greater transparency and flexibility but lower reflectivity, commonly used in packaging and protective coverings. The choice between metalized and non-metalized Mylar depends on specific application needs such as thermal insulation, moisture barrier effectiveness, or optical clarity.

Barrier Properties: Moisture, Gas, and Light Protection

Metalized Mylar offers superior barrier properties by effectively blocking moisture, gases like oxygen and nitrogen, and light, which extends product shelf life and preserves freshness. Non-metalized Mylar, while still providing moderate protection, is more permeable to moisture and gases, making it less effective for long-term preservation. The reflective metalized layer enhances light protection, preventing degradation caused by UV rays, unlike its non-metalized counterpart.

Durability and Strength: How Metalization Impacts Performance

Metalized Mylar exhibits enhanced durability and strength compared to non-metalized Mylar due to the reflective metal coating, which adds structural reinforcement and resistance to tearing. The metalized layer improves barrier properties against moisture, gases, and UV light, extending material lifespan in harsh environments. In contrast, non-metalized Mylar, while flexible and lightweight, lacks the additional protective and reinforcing benefits provided by metalization, resulting in lower overall performance in demanding applications.

Visual Appearance: Differences in Finish and Aesthetics

Metalized Mylar features a reflective, shiny surface that enhances brightness and creates a sleek, mirror-like finish, often used for decorative or insulating purposes. Non-metalized Mylar has a matte or translucent finish offering a more subdued and flexible aesthetic, suitable for applications requiring transparency or minimal glare. The choice between metalized and non-metalized Mylar directly affects the visual appeal and functionality in packaging, insulation, and artistic projects.

Environmental Considerations: Recycling and Sustainability

Metalized Mylar poses significant challenges for recycling due to its multi-layered structure, which complicates material separation and often leads to landfill disposal, raising environmental concerns. Non-metalized Mylar, made solely from polyethylene terephthalate (PET), is more easily recyclable and presents a more sustainable option by supporting circular material use. Choosing non-metalized Mylar reduces ecological impact through improved recyclability and decreased reliance on complex processing techniques.

Cost Analysis: Price Differences and Value Factors

Metalized Mylar typically costs 20-30% more than non-metalized Mylar due to the additional aluminum coating process, which enhances reflectivity and barrier properties but increases production complexity. Non-metalized Mylar offers a more economical option for applications where moisture resistance and durability are sufficient without the need for high reflectivity or enhanced insulation. Value factors for choosing between the two include specific application requirements, with metalized Mylar preferred in insulation, packaging, and reflective uses, justifying the higher price with extended functional benefits.

Choosing the Right Mylar: Industry-Specific Recommendations

Metalized Mylar offers superior reflectivity and moisture resistance, making it ideal for insulation in construction and high-performance packaging in the food industry. Non-metalized Mylar provides enhanced flexibility and clarity, preferred for applications like printing, labeling, and decorative uses in retail and marketing sectors. Selecting the right Mylar depends on specific industry requirements, balancing properties such as durability, barrier protection, and visual appeal.

Metalized Mylar vs Non-metalized Mylar Infographic

materialdif.com

materialdif.com