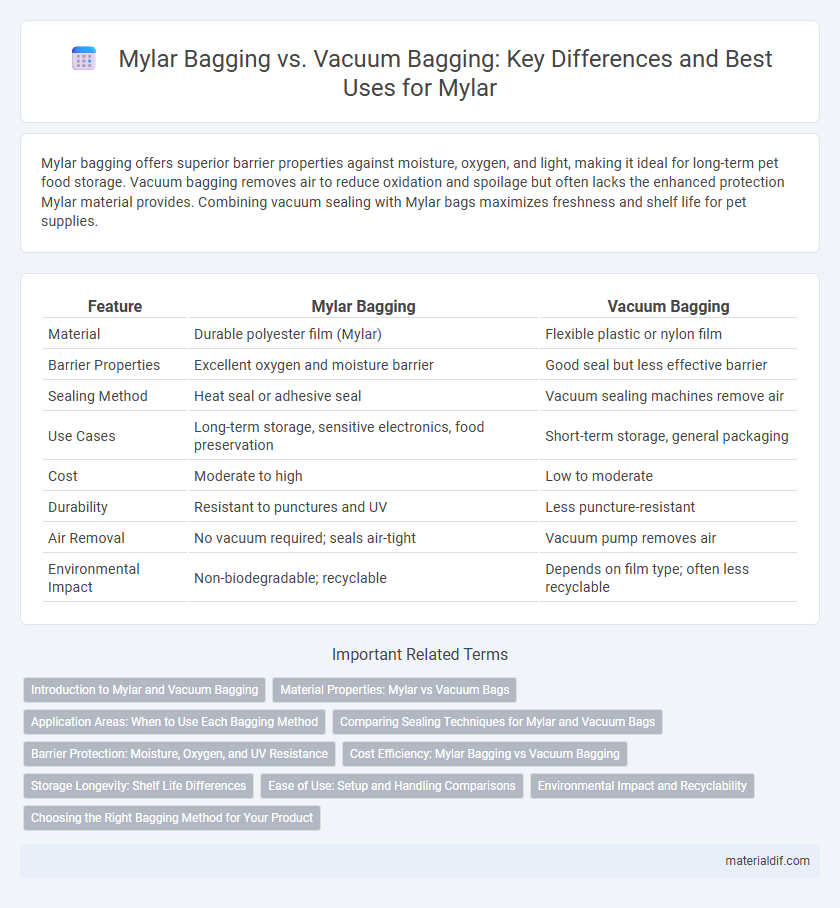

Mylar bagging offers superior barrier properties against moisture, oxygen, and light, making it ideal for long-term pet food storage. Vacuum bagging removes air to reduce oxidation and spoilage but often lacks the enhanced protection Mylar material provides. Combining vacuum sealing with Mylar bags maximizes freshness and shelf life for pet supplies.

Table of Comparison

| Feature | Mylar Bagging | Vacuum Bagging |

|---|---|---|

| Material | Durable polyester film (Mylar) | Flexible plastic or nylon film |

| Barrier Properties | Excellent oxygen and moisture barrier | Good seal but less effective barrier |

| Sealing Method | Heat seal or adhesive seal | Vacuum sealing machines remove air |

| Use Cases | Long-term storage, sensitive electronics, food preservation | Short-term storage, general packaging |

| Cost | Moderate to high | Low to moderate |

| Durability | Resistant to punctures and UV | Less puncture-resistant |

| Air Removal | No vacuum required; seals air-tight | Vacuum pump removes air |

| Environmental Impact | Non-biodegradable; recyclable | Depends on film type; often less recyclable |

Introduction to Mylar and Vacuum Bagging

Mylar bagging utilizes highly durable polyester film known for its moisture and oxygen barrier properties, crucial for long-term preservation of sensitive items. Vacuum bagging involves removing air from a bag, typically plastic or Mylar, to create a tight seal that extends the shelf life of products by minimizing exposure to environmental contaminants. Both methods are widely used in food storage and electronic component packaging, highlighting Mylar's superior puncture resistance and vacuum bagging's efficiency in reducing oxidation.

Material Properties: Mylar vs Vacuum Bags

Mylar bags are crafted from biaxially-oriented polyethylene terephthalate (BoPET), offering superior tensile strength, puncture resistance, and an exceptional moisture and oxygen barrier, making them ideal for long-term preservation. In contrast, traditional vacuum bags are typically made from multi-layered polyethylene or nylon blends, providing flexibility and effective air removal but with less durability and barrier protection compared to Mylar. The enhanced chemical inertness and temperature resistance of Mylar contribute to its preference in applications requiring extended shelf life and protection against environmental factors.

Application Areas: When to Use Each Bagging Method

Mylar bagging excels in preserving light-sensitive and moisture-sensitive products such as electronics, pharmaceuticals, and food items by providing a strong barrier against oxygen and UV exposure. Vacuum bagging is ideal for composite manufacturing, woodworking, and repair applications where removing air improves material consolidation and structural integrity. Choose Mylar bags for long-term storage requiring airtight protection and vacuum bags for processes demanding precise air evacuation and pressure control.

Comparing Sealing Techniques for Mylar and Vacuum Bags

Mylar bagging uses heat-sealed edges to create an airtight barrier, effectively preserving contents by preventing oxygen and moisture infiltration. Vacuum bagging removes air mechanically before sealing, ensuring a tighter fit around items and reducing oxidation but requiring specialized equipment. Comparing sealing techniques, Mylar's heat seal offers a simple, reliable method, while vacuum bagging delivers enhanced compression and protection but with increased complexity and cost.

Barrier Protection: Moisture, Oxygen, and UV Resistance

Mylar bagging provides superior barrier protection against moisture, oxygen, and UV light due to its polyethylene terephthalate (PET) film composition, ensuring extended preservation of contents. Vacuum bagging removes air to reduce oxygen exposure but relies on the bag material, which may lack the same high resistance to moisture and UV radiation as Mylar. Combining vacuum sealing with Mylar bags optimizes protection by minimizing oxygen and moisture ingress while blocking harmful UV rays.

Cost Efficiency: Mylar Bagging vs Vacuum Bagging

Mylar bagging offers cost efficiency by utilizing durable, reusable films that reduce long-term expenses compared to single-use vacuum bags. Vacuum bagging requires specialized equipment that can increase initial investment and maintenance costs, making Mylar bags more economical for bulk or frequent applications. The ability of Mylar bags to maintain airtight seals without constant suction further lowers operational costs versus vacuum bagging systems.

Storage Longevity: Shelf Life Differences

Mylar bagging extends storage longevity by providing a superior oxygen and moisture barrier compared to vacuum bagging, significantly reducing oxidation and spoilage over time. Vacuum bagging removes air but relies on the bag's material properties, which may allow gradual permeation of gases, potentially shortening shelf life. For long-term preservation, Mylar bags with oxygen absorbers offer a more effective solution, maintaining product freshness for several years beyond typical vacuum-sealed storage.

Ease of Use: Setup and Handling Comparisons

Mylar bagging offers a straightforward setup process with pre-sealed edges and heat-sealable materials, making it easier for beginners to handle without specialized equipment. Vacuum bagging requires a vacuum pump and airtight seals, adding complexity and time to the setup, which may challenge users without technical experience. The lightweight and flexible nature of Mylar bags enhances maneuverability during packaging compared to the rigid components often involved in vacuum bagging systems.

Environmental Impact and Recyclability

Mylar bagging offers superior environmental benefits due to its excellent barrier properties that extend product lifespan and reduce waste from spoilage, supporting sustainability. Vacuum bagging, while effective in preserving freshness, often uses multi-layer plastics that complicate recyclability and increase environmental impact. Choosing Mylar bags enhances recyclability efforts as they are typically made from polyethylene terephthalate (PET), a widely recycled material, unlike many vacuum-sealing films.

Choosing the Right Bagging Method for Your Product

Mylar bagging offers superior moisture and oxygen barrier properties, making it ideal for long-term storage of sensitive products like electronics and food. Vacuum bagging excels in removing air to prevent oxidation and mold, benefiting items requiring tight compression and freshness. Selecting the right bagging method depends on product sensitivity, storage duration, and environmental exposure to ensure optimal preservation.

Mylar Bagging vs Vacuum Bagging Infographic

materialdif.com

materialdif.com