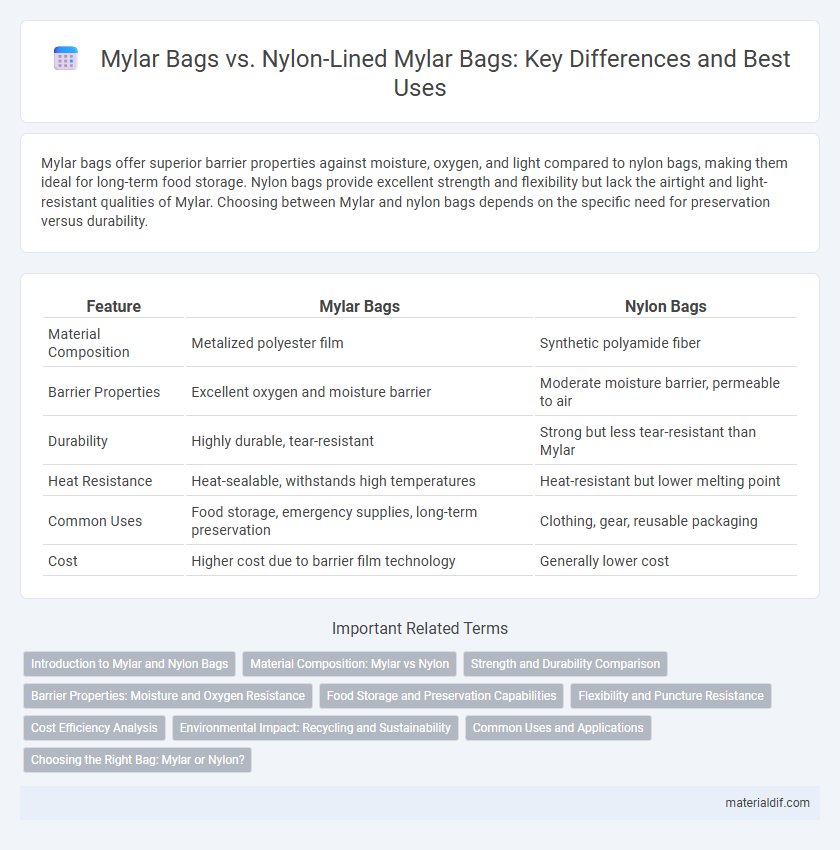

Mylar bags offer superior barrier properties against moisture, oxygen, and light compared to nylon bags, making them ideal for long-term food storage. Nylon bags provide excellent strength and flexibility but lack the airtight and light-resistant qualities of Mylar. Choosing between Mylar and nylon bags depends on the specific need for preservation versus durability.

Table of Comparison

| Feature | Mylar Bags | Nylon Bags |

|---|---|---|

| Material Composition | Metalized polyester film | Synthetic polyamide fiber |

| Barrier Properties | Excellent oxygen and moisture barrier | Moderate moisture barrier, permeable to air |

| Durability | Highly durable, tear-resistant | Strong but less tear-resistant than Mylar |

| Heat Resistance | Heat-sealable, withstands high temperatures | Heat-resistant but lower melting point |

| Common Uses | Food storage, emergency supplies, long-term preservation | Clothing, gear, reusable packaging |

| Cost | Higher cost due to barrier film technology | Generally lower cost |

Introduction to Mylar and Nylon Bags

Mylar bags, made from biaxially-oriented polyethylene terephthalate (BoPET), offer superior moisture, oxygen, and light barrier properties, making them ideal for long-term food storage and preservation. Nylon bags provide excellent puncture resistance and flexibility, commonly utilized in vacuum sealing applications where strength and durability are critical. Both materials serve distinct purposes, with Mylar excelling in airtight protection and Nylon in physical toughness.

Material Composition: Mylar vs Nylon

Mylar bags are composed of biaxially-oriented polyethylene terephthalate (BoPET), known for its high tensile strength, chemical stability, and excellent barrier properties against oxygen, moisture, and light. Nylon bags, made from polyamide fibers, offer superior flexibility and puncture resistance but have lower impermeability compared to Mylar's metallized layers. The unique multi-layer structure of Mylar combines polyester with aluminum coating, enhancing its protective qualities beyond the polymer-based composition of nylon bags.

Strength and Durability Comparison

Mylar bags exhibit superior strength and durability due to their multi-layer polyester film construction, which provides excellent puncture resistance and barrier protection against moisture and oxygen. Nylon bags offer high tensile strength and flexibility but are more prone to punctures and less effective at blocking environmental factors. For long-term storage and protection, Mylar bags outperform nylon bags by maintaining product integrity in harsh conditions.

Barrier Properties: Moisture and Oxygen Resistance

Mylar bags exhibit superior barrier properties compared to nylon bags, offering exceptional moisture and oxygen resistance that effectively preserves product freshness and extends shelf life. The metallized polyester film in Mylar provides a nearly impermeable barrier against gases and humidity, preventing contamination and degradation. Nylon bags, while strong and flexible, have higher permeability, making them less effective for applications requiring long-term protection from moisture and oxygen.

Food Storage and Preservation Capabilities

Mylar bags offer superior food storage and preservation due to their excellent barrier properties against oxygen, moisture, and light, which significantly extend shelf life. Nylon bags provide good durability and puncture resistance but lack the same level of airtight sealing and barrier protection, making them less effective for long-term food preservation. For optimal food storage, Mylar bags combined with oxygen absorbers create an environment that minimizes spoilage and maintains freshness.

Flexibility and Puncture Resistance

Mylar bags offer superior puncture resistance due to their multi-layered construction, making them ideal for long-term storage of sharp or heavy items. Nylon bags provide greater flexibility and durability in handling, bending more easily without tearing under stress. Choosing between Mylar and Nylon depends on the need for rigidity and puncture protection versus pliability and toughness in demanding environments.

Cost Efficiency Analysis

Mylar bags offer superior cost efficiency compared to nylon bags due to their lower material costs and enhanced barrier properties that reduce product spoilage and extend shelf life. The durability and moisture resistance of Mylar reduce the need for multiple packaging layers, lowering overall packaging expenses. Nylon bags, while durable, often incur higher production costs and may require additional treatments to match Mylar's protective qualities, making Mylar a more economically advantageous choice for long-term storage.

Environmental Impact: Recycling and Sustainability

Mylar bags offer superior barrier properties that extend product shelf life, reducing food waste and supporting sustainability efforts. They are often made from a combination of polyester and aluminum, which can be more challenging to recycle compared to nylon, but specialized recycling programs are emerging to handle Mylar materials. Nylon bags, while easier to recycle and biodegradable in some forms, typically provide less protection, potentially leading to increased packaging waste.

Common Uses and Applications

Mylar bags are commonly used for long-term food storage, vacuum sealing, and protecting sensitive electronics due to their high barrier properties against moisture, oxygen, and light. Nylon bags are favored in industrial and medical applications where durability, puncture resistance, and breathability are essential, such as in packaging pharmaceuticals and heavy-duty goods. Both materials serve packaging needs but differ significantly in their protective qualities and application environments.

Choosing the Right Bag: Mylar or Nylon?

Mylar bags offer superior moisture and oxygen barrier properties, making them ideal for long-term food storage and preservation of sensitive items. Nylon bags provide excellent durability and flexibility, with resistance to punctures and abrasion suited for heavy-duty or reusable applications. Selecting the right bag depends on whether the priority is airtight protection with Mylar or mechanical strength and reusability with nylon.

Mylar Bags vs Nylon Bags Infographic

materialdif.com

materialdif.com